Keyboard structure

A keyboard and keycap technology, applied in the direction of electrical components, electric switches, user/computer interaction input/output, etc., can solve the problems of product quality and pass rate reduction, difficulty, poor smoothness, etc., to reduce the inconvenience of use and difficulty, improve the overall use function, improve the effect of quality and pass rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to achieve the above-mentioned purpose and effect, the technical means and structure adopted by the present invention, the features and functions of the preferred embodiments of the present invention will be described in detail as follows, so as to facilitate a complete understanding.

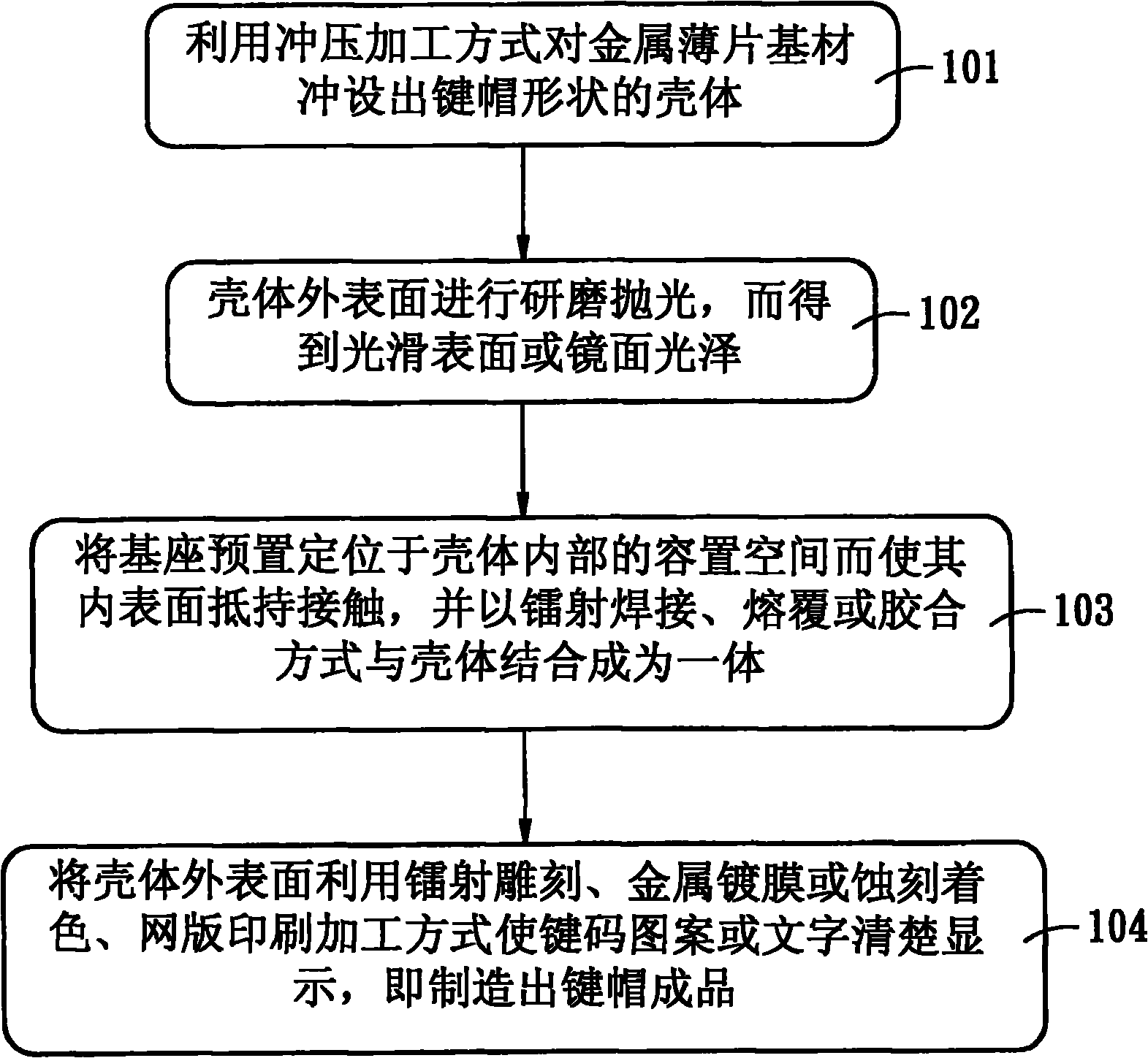

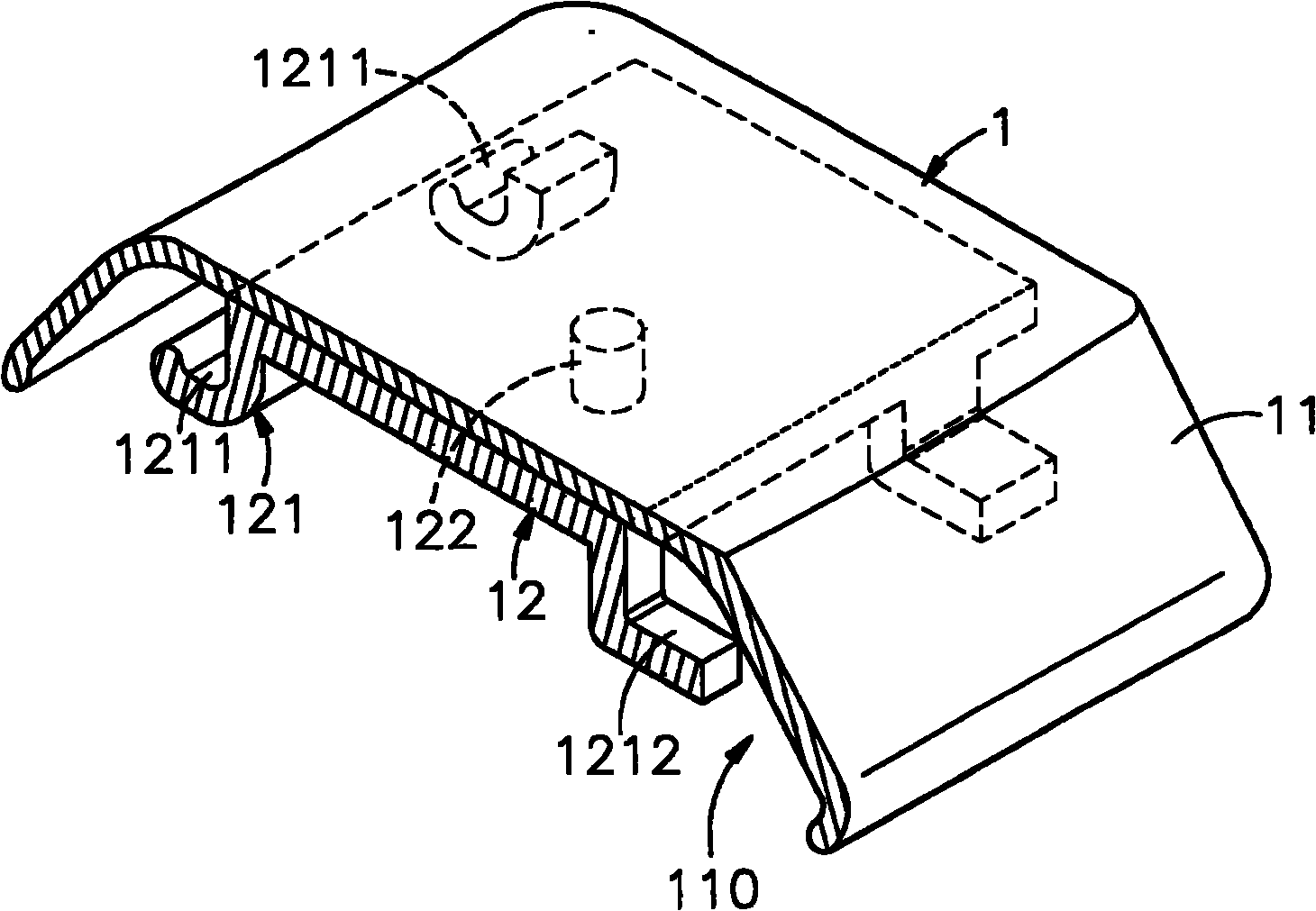

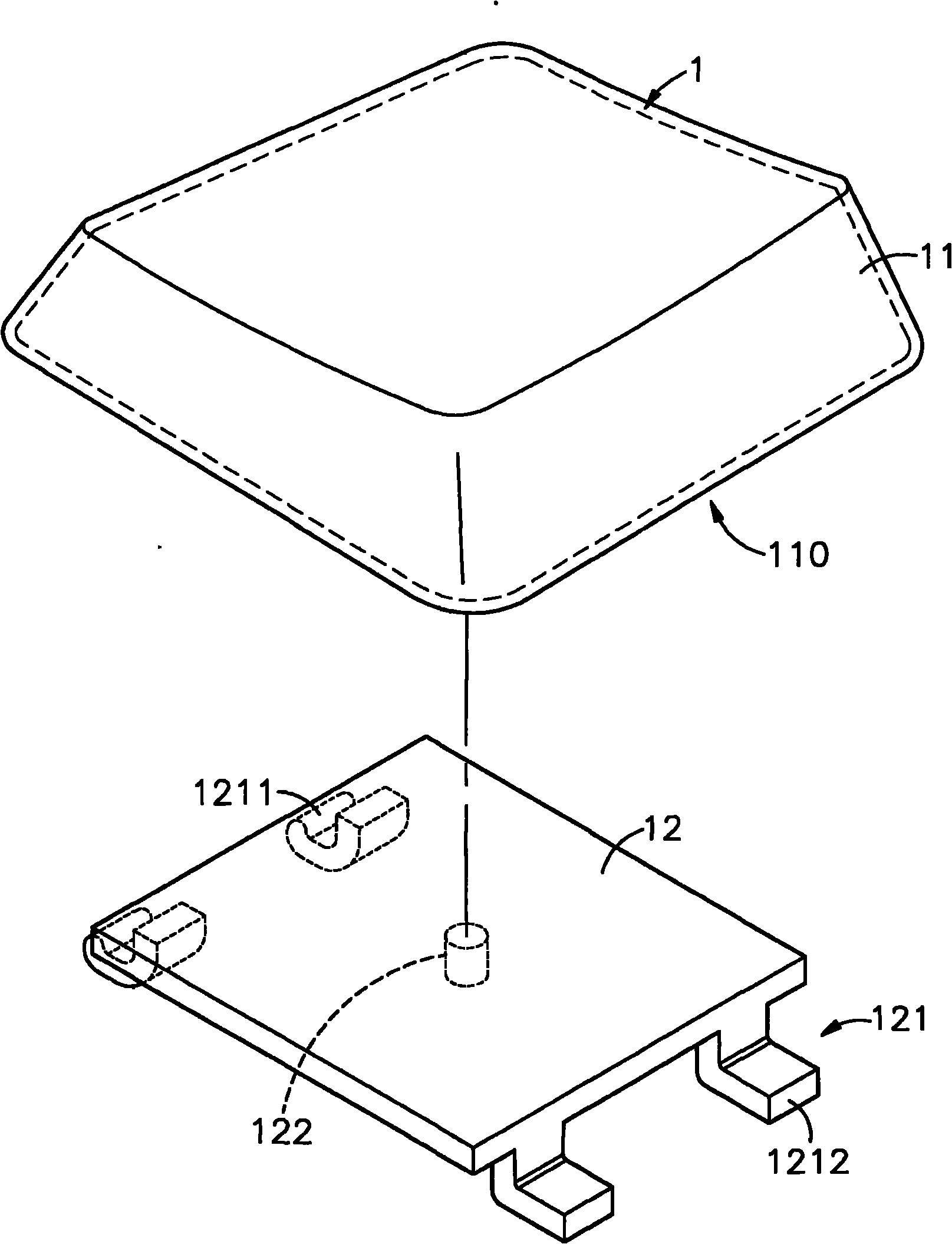

[0027] see figure 1 , figure 2 , image 3 Shown are respectively the manufacturing flow chart, structural diagram and three-dimensional exploded view of the present invention. It can be clearly seen from the figure that the manufacturing method of the keyboard of the present invention is processed according to the following process steps:

[0028] (101) punch out a keycap-shaped housing 11 on the sheet metal base material by means of a stamping process;

[0029] (102) Grinding and polishing the outer surface of the housing 11 to obtain a smooth surface or mirror luster;

[0030] (103) Pre-positioning the base 12 in the accommodating space 110 inside the housing 11 so that it...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com