Preparation method for improving hydrogen storage performance of AB2C9 La-Mg-Ni-based alloy

A base alloy and alloy technology, applied in the field of metal hydride batteries, can solve the problems of electrochemical capacity decay hindering application, and achieve the effects of good electrochemical performance, guaranteed uniformity and easy activation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

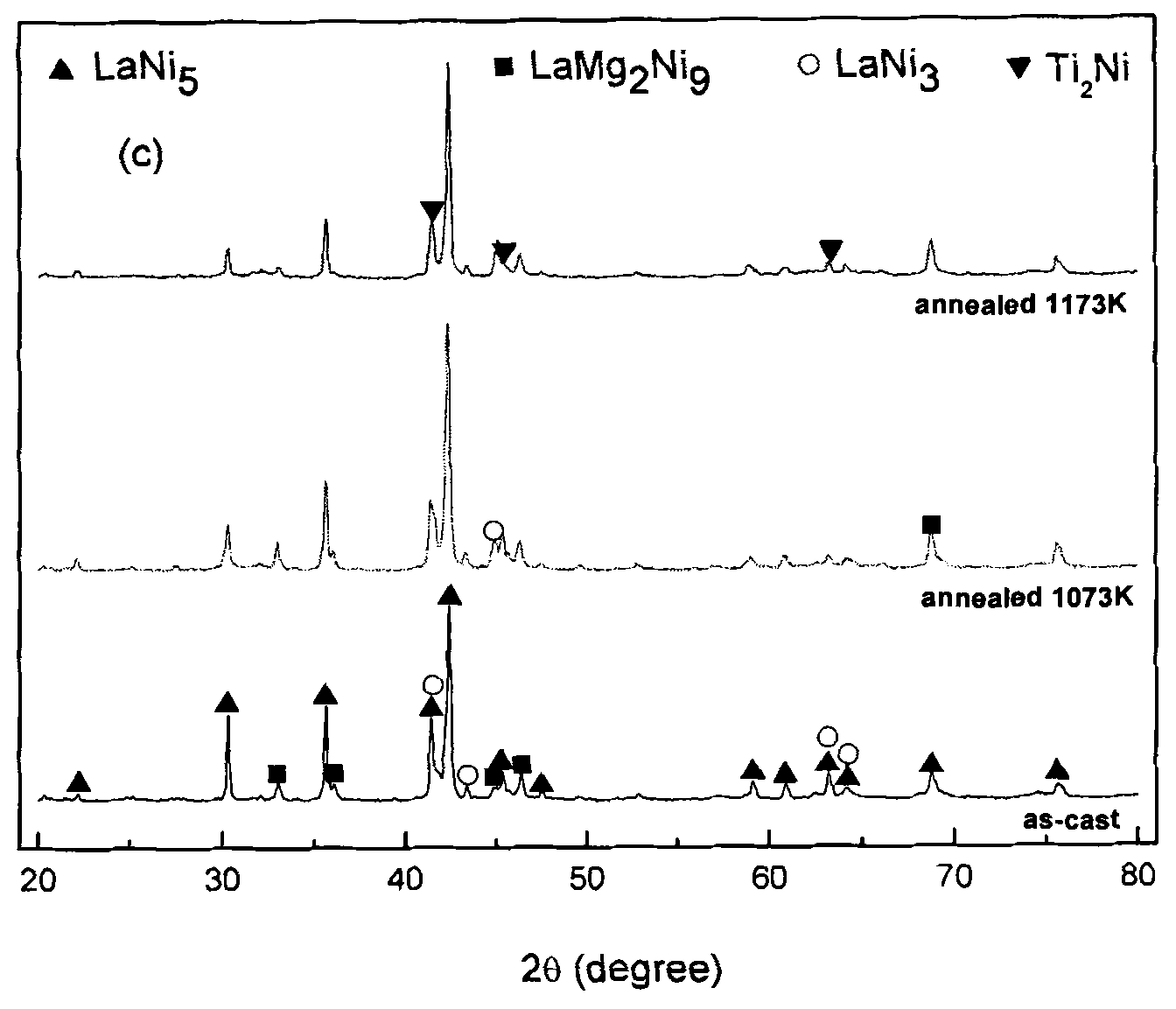

[0034] La 2-x Ti x MgNi 9 (x=0.1, 0.2 or 0.3) alloy according to the atomic ratio of La:Ti:Mg:Ni=(2-x):x:1:9 (x=0.1, 0.2 or 0.3) with a good sample (considering Mg in volatilization during the smelting process, Mg mass excess 10%), then first put Ti and Ni with similar melting points in the sample into the reactor of the magnetic levitation induction melting furnace, and after 3 times of vacuuming and argon cleaning, in about 1atm argon Under the protection of air, gradually increase the frequency from zero until the alloy is completely suspended. At this time, the frequency value is the highest frequency for smelting. The alloy is left at the highest frequency for 60 seconds, and then the frequency value is quickly adjusted back to zero to stop heating. After cooling down to room temperature naturally, it was taken out from the reactor, and smelted into Ti-Ni alloy repeatedly in this way twice. According to the above smelting method, La and Ti-Ni are repeatedly melted into...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com