Refractory castable for desulfurizing spray gun for pretreating molten iron

A pretreatment technology for refractory castables and molten iron, applied in the field of refractory materials, can solve the problems of reduced service life of desulfurization spray guns, increase desulfurization powder, etc., achieve good thermal shock resistance, improve thermal shock resistance, and reduce cracks.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The substantive features and significant progress of the present invention will be further clarified below through specific examples and comparison with the characteristics of the currently used refractory castables.

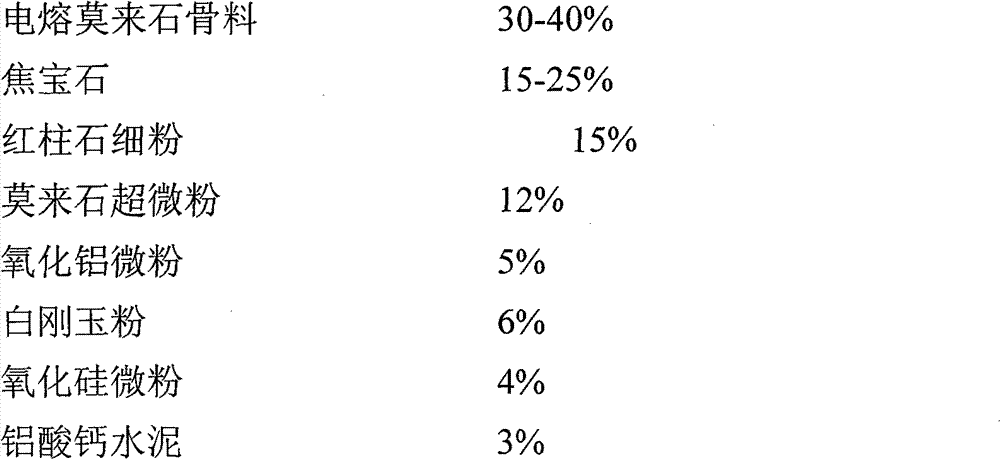

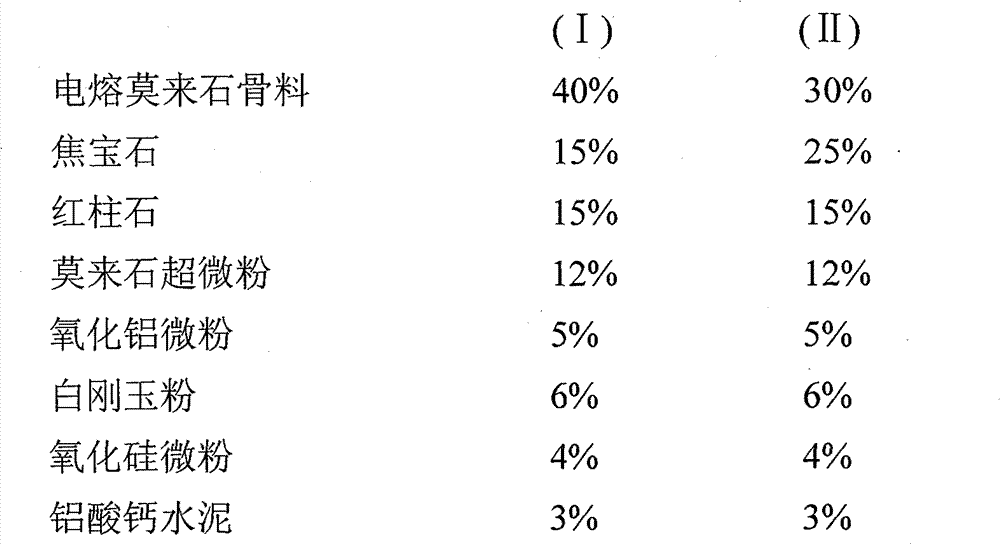

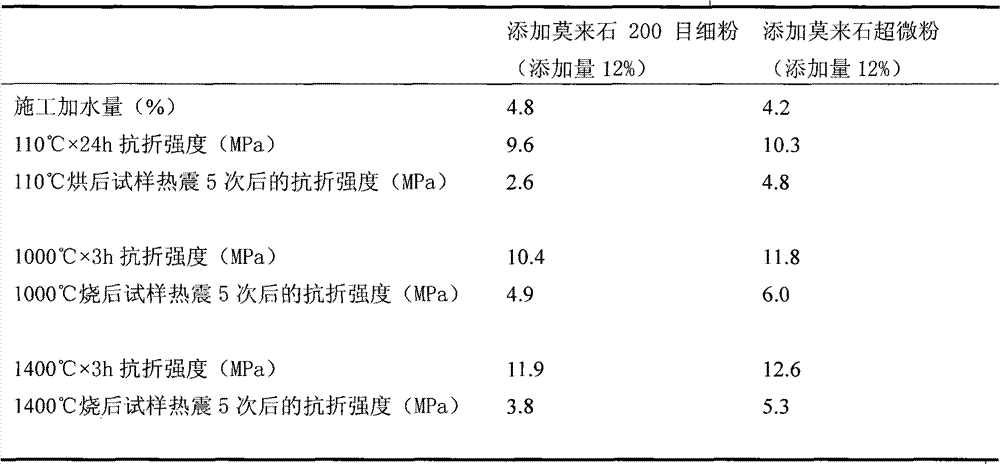

[0025] In the first column of Table 2, the original ratio means the thermal shock resistance of the refractory castable without adding coke gemstone, andalusite and mullite ultrafine powder and the actual furnace times. The original ratio is composed of 70% fused Mo Stone aggregate, 12% mullite fine powder (≤40μm), 5% alumina fine powder, 4% white corundum powder, 4% silica fine powder, 5% calcium aluminate cement, Examples 1 and 2 are to reduce electricity The amount of fused mullite aggregate is 30-40%, while increasing the amount of coke gemstone and andalusite, and substituting mullite ultrafine powder for mullite fine powder, achieved good thermal shock resistance and thermal conductivity, Thereby increasing the service life.

[0026] Table 2

[00...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com