Collapsible mold and method of manufacturing the same

A collapsible, casting mold technology, applied in the direction of manufacturing tools, casting molding equipment, casting molds, etc., can solve the problems of rough surface, insufficient to inhibit the mold from absorbing moisture, unable to store the core for a long time, etc., to improve the surface characteristics , the effect of inhibiting water absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

[0019] Embodiment 1: Manufacturing method of salt core

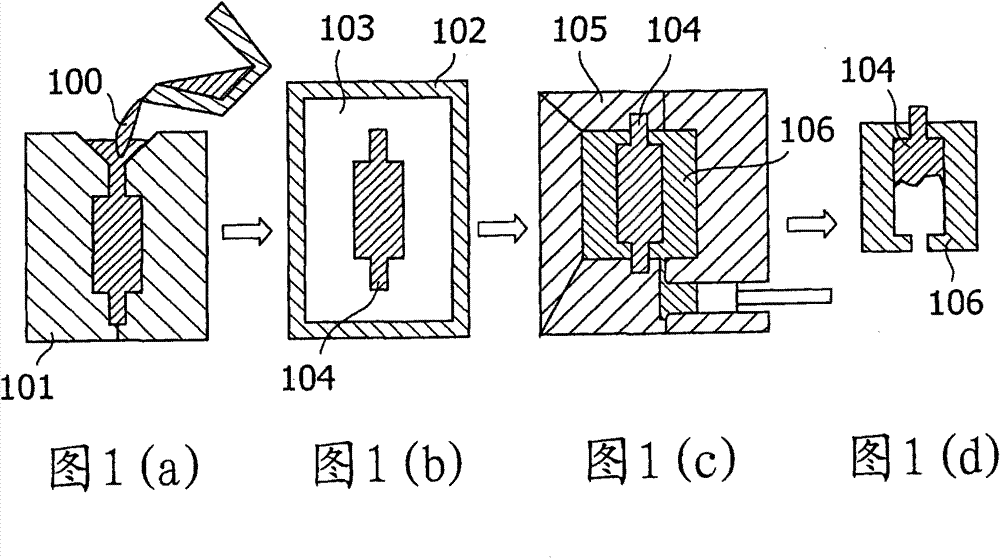

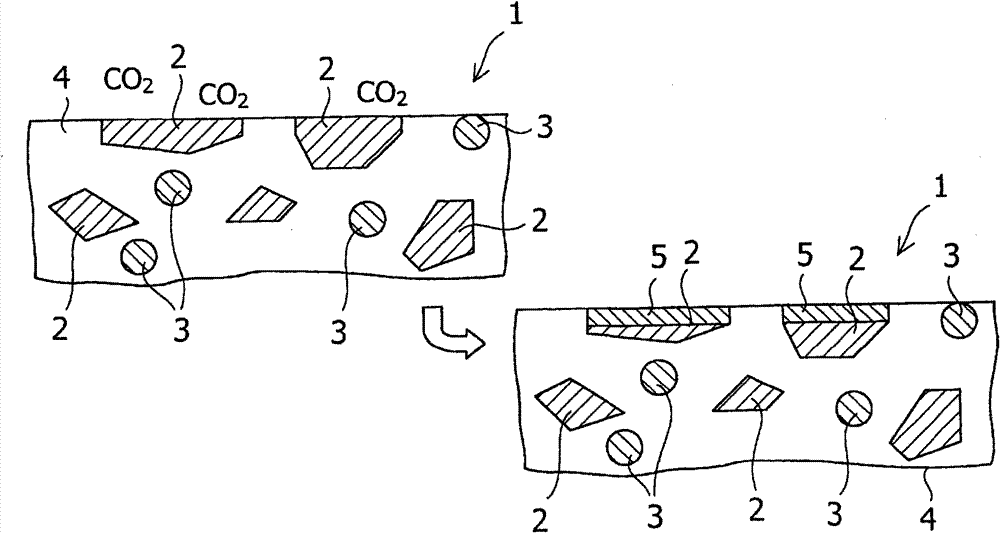

[0020] Next, a method of manufacturing the collapsible mold according to the present invention in the case where the collapsible mold according to the present invention is a salt core will be explained. The method of making the salt core includes the steps of: melting and making a mold composition; casting the salt core; and contacting the salt core with carbon dioxide. The salt core is cast by: melting and making a mold composition; and casting the mold composition.

[0021] Steps to Melt and Make Mold Composition

[0022] In the step of melting and manufacturing the mold composition for the salt core, materials including the salt to be melted, the alkaline earth metal compound and the refractory are mixed. As the alkaline earth metal compound, calcium hydroxide, magnesium hydroxide, calcium oxide, and magnesium oxide are preferable.

[0023] As the salt, salts such as sodium chloride, potassium chloride, sodium sulf...

Embodiment approach 2

[0038] Embodiment 2; Lost wax casting mold

[0039] Next, a method of manufacturing a collapsible mold according to Embodiment 2 of the present invention in the case where the collapsible mold is a lost wax casting mold will be described. The manufacturing method according to this embodiment comprises the steps of: preparing a mold composition; shaping the mold composition; sintering the shape; and treating the formed shape with carbon dioxide.

[0040] Steps to prepare mold composition

[0041] In the step of preparing the mold composition, a material including a refractory material, a binder, and at least one of calcium carbonate and magnesium carbonate is mixed.

[0042] For calcium carbonate and magnesium carbonate, one of these substances or a mixture of these substances can be used. Calcium carbonate and magnesium carbonate are preferably mixed at 5% to 75% by weight of the molding composition. When the content of these substances is less than 5% by weight, sufficient...

Embodiment

[0066] casting core; salt core

[0067] A mold composition was prepared by mixing 27.8% by weight NaCl, 34.7% by weight KCl, 11.2% by weight mullite, and 26.3% by weight slaked lime. The mold composition is melted by being heated to 750° C., and then poured into a mold for forming a core. The cores were removed from the mold and exposed to carbon dioxide atmospheres at temperatures of 500°C, 400°C and 300°C, respectively. Then, the core in this environment was naturally cooled to room temperature. Also, another core cast at the same time was naturally cooled in the atmosphere and then exposed to a carbon dioxide environment at room temperature. The cores were stored in a low humidity container (room temperature, 40% humidity) for 2 days or 30 days. After that, the surface states of the cores were compared by using a stereo microscope.

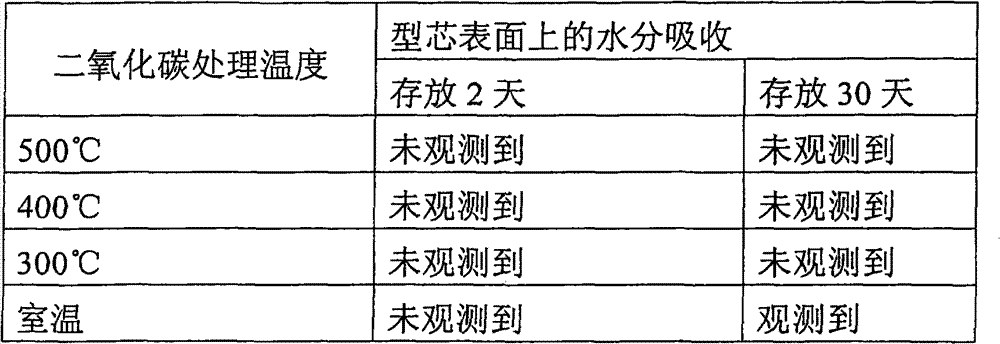

[0068] Table 1 shows the comparison results. In the case where the carbon dioxide treatment was performed at room temperature, a change i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com