Selective hydrogenation catalyst and application thereof

A technology of selective hydrogenation and catalyst, applied in the direction of selective hydrogenation, physical/chemical process catalyst, metal/metal oxide/metal hydroxide catalyst, etc., which can solve the problem of easy loss of catalyst active components and difficult regeneration. , high price and other problems, to achieve the effect of excellent hydrogenation activity and selectivity, reducing content and highlighting selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

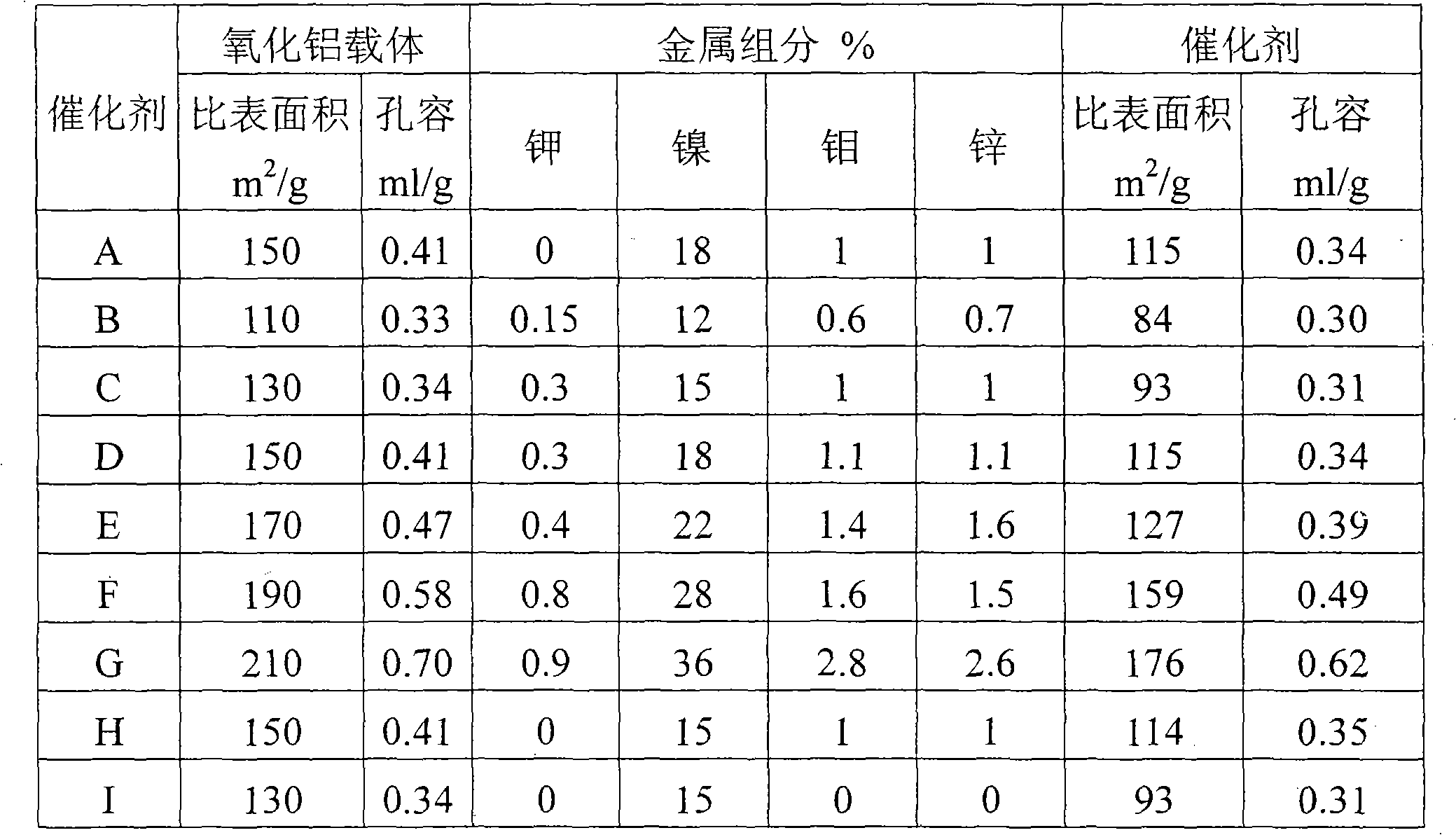

[0038] The alumina carrier formed by pseudo-boehmite produced by Beijing Research Institute of Chemical Industry was used. The specific surface area and pore volume of the carrier are listed in Table 1. The alumina carrier was impregnated with an aqueous solution containing nickel nitrate, ammonium heptamolybdate and zinc nitrate. Then dry, roast at 400° C., and then reduce with hydrogen at 400° C. for 4 hours to obtain different catalysts A. The metal component content of the catalyst is listed in Table 1.

Embodiment 2

[0040] The alumina carrier formed by pseudo-boehmite produced by Beijing Research Institute of Chemical Industry is used. The specific surface area and pore volume of the carrier are listed in Table 1. First, the alumina carrier is impregnated with an aqueous solution of potassium bicarbonate, then dried, and then washed with An aqueous solution of nickel, ammonium heptamolybdate and zinc nitrate impregnated the alumina support treated with potassium bicarbonate, then dried, calcined at 400 °C, and then reduced with hydrogen at 400 °C for 4 hours to obtain different catalysts B, C and D, the metal component content of each catalyst is listed in Table 1.

Embodiment 3

[0042] The alumina carrier formed by pseudoboehmite produced by Beijing Research Institute of Chemical Industry is used. The specific surface area and pore volume of the carrier are listed in Table 1. First, the alumina carrier is impregnated with an aqueous solution of potassium hydroxide, then dried, and then washed with acetic acid containing An aqueous solution of nickel, ammonium heptamolybdate and zinc acetate was spray-coated on an alumina support treated with potassium hydroxide, then dried, calcined at 400°C, and reduced with hydrogen at 400°C for 4 hours to obtain different catalysts E, F and G, the metal component content of each catalyst is listed in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com