BC febrifugal refreshment paste for auxiliary treatment of fever and emergent physical hypothermia and preparation thereof

A technology of physical cooling and adjuvant therapy, applied in the direction of microorganism-based methods, antipyretics, biochemical equipment and methods, etc., can solve the problem that the antipyretic Xingnao patch has no obvious antipyretic effect, and bacterial cellulose-based antipyretics have not yet been seen. Heat refreshment paste, take away skin heat and other problems, to achieve good application prospects, easy to operate, soft and light texture effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] 1. Preparation and treatment of BC membrane

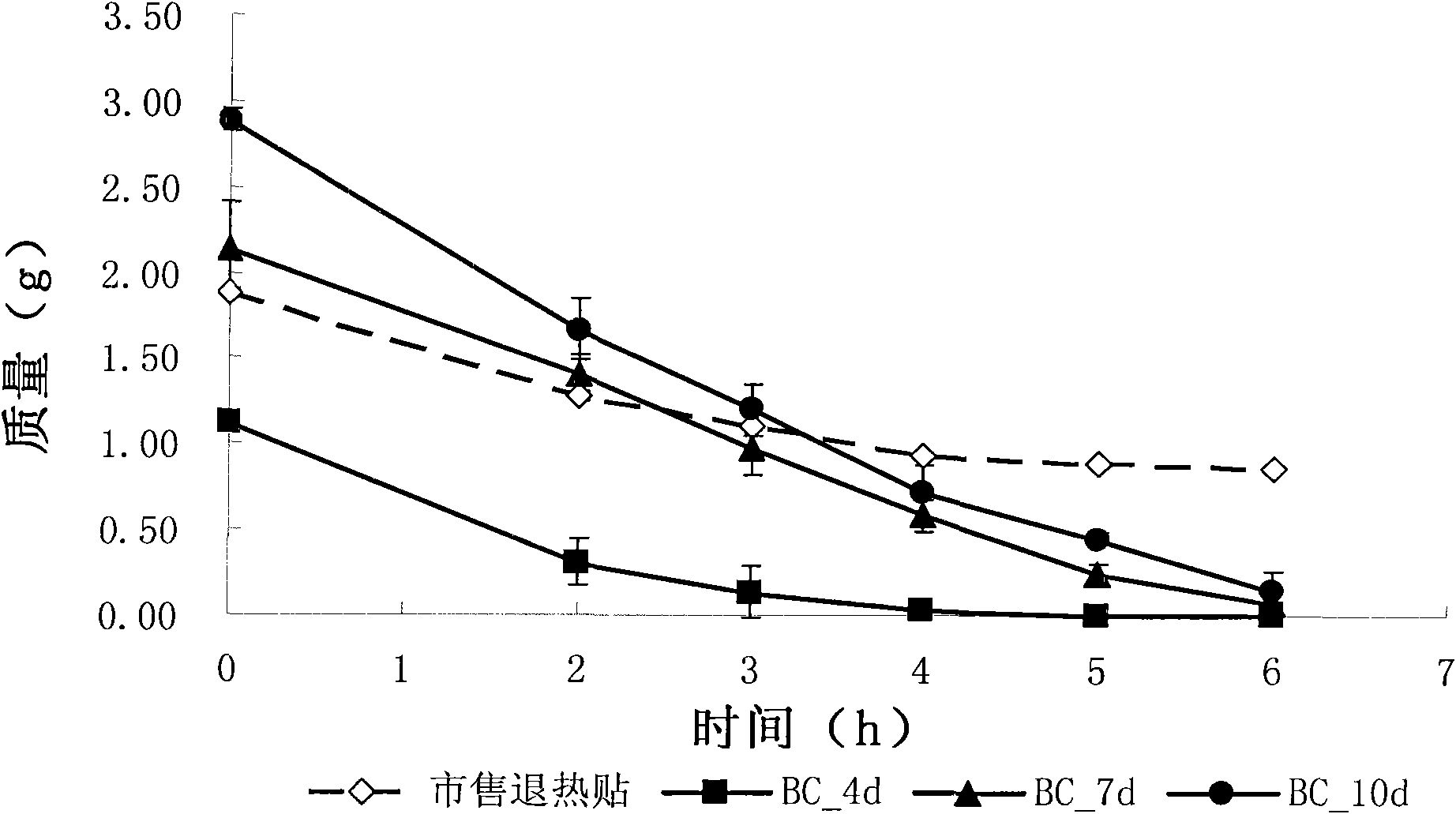

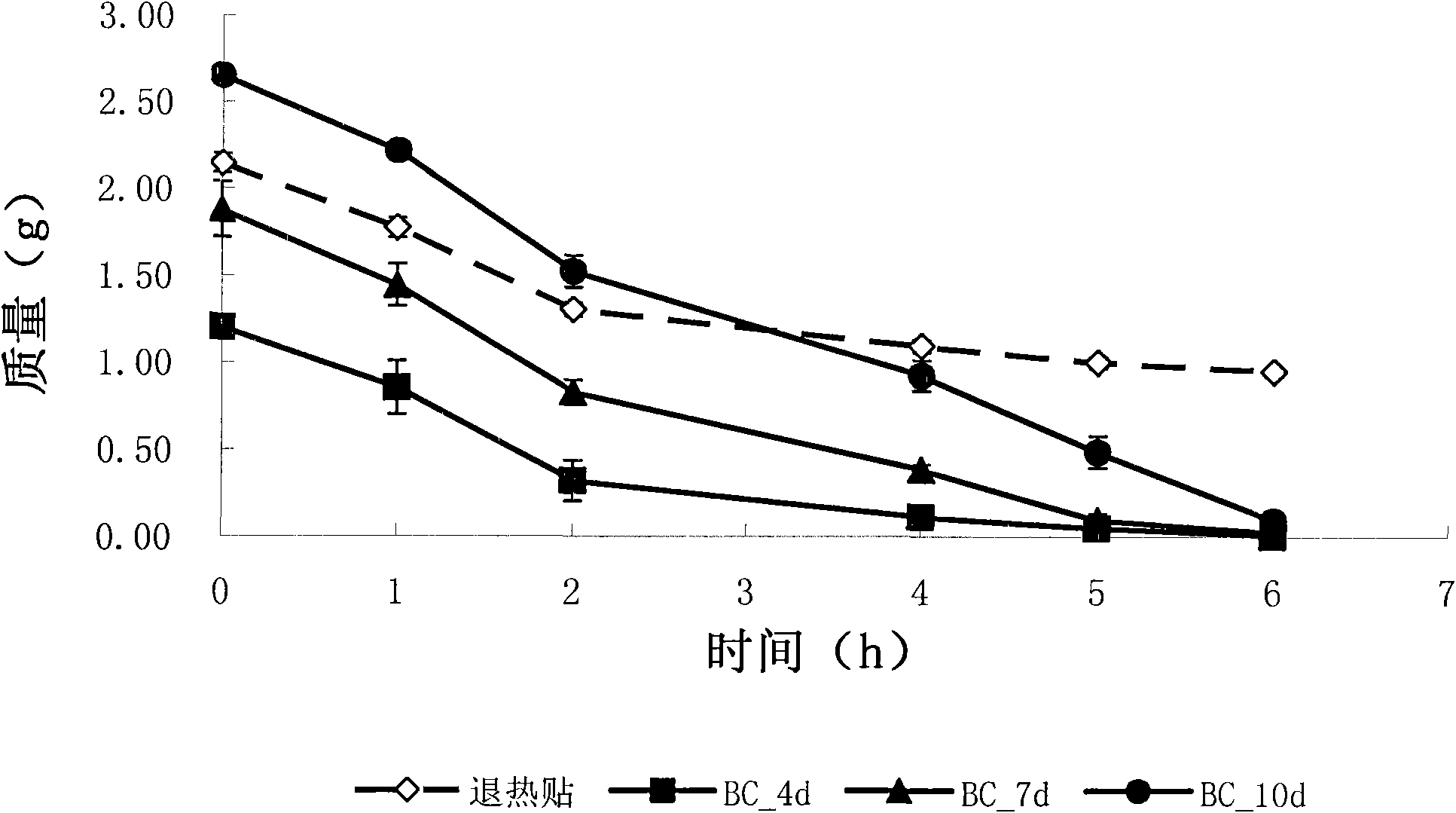

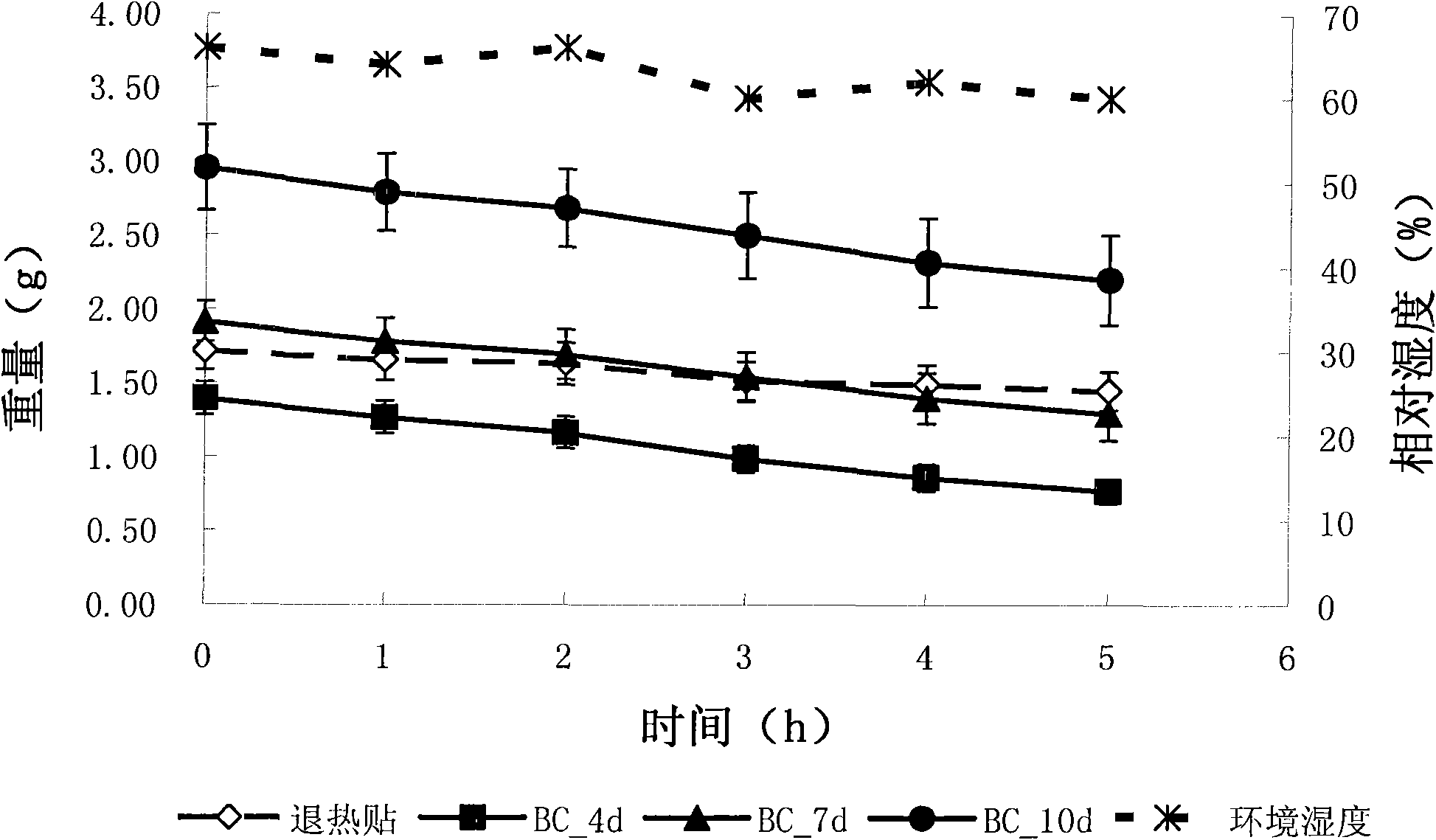

[0038]Acetobacter xylinum (Acetobacter xylinum) was expanded and cultivated in the seed medium at 30°C for 24 hours according to the inoculation amount of 2 to 3 inoculation loops, and then transferred to the fermentation medium according to the inoculum amount of 6% at 30°C for static culture respectively 4, 7,10 days, harvest bacterial cellulose (BC) wet film; The prepared BC film is soaked in 1% NaOH solution in 80 ℃ of water baths until BC film turns white and translucent, then the BC film that makes and commercially available Antipyretic patches were cut into rectangles with a diameter of 2cm×4.5cm for later use, among which the thickness of BC_4d was 1.61mm, the thickness of BC_7d was 2.78mm, the thickness of BC_10d was 3.44mm, and the thickness of commercially available antipyretic patches was 2.50mm;

[0039] Among them, the seed medium and the fermentation medium are: mannitol, glucose, sucrose or fructose 2.5g, pep...

Embodiment 2

[0048] 1. Preparation and treatment of BC membrane

[0049] Gluconacetobacter xylinus was cultured in the seed medium at 30°C for 24 hours according to the inoculum amount of 2-3 inoculation loops, and then transferred to the fermentation medium at 6% inoculum amount for static culture at 30°C. 4,7,10 days, harvest bacterial cellulose (BC) wet film; Prepared BC film is soaked in 2% NaOH solution in 90 ℃ of water baths until BC film becomes white and translucent, then the BC film that makes is mixed with Commercially available antipyretic patches are cut into rectangles with a diameter of 2cm×4.5cm for later use, among which the thickness of BC_4d is 1.62mm, the thickness of BC_7d is 2.74mm, the thickness of BC_10d is 3.47mm, and the thickness of commercially available antipyretic patches is 2.50mm ;

[0050] Among them, both the seed medium and the fermentation medium are: mannitol, glucose, sucrose or fructose 10g, yeast extract 0.5g, peptone 0.5g, citric acid 0.115g, Na 2 ...

Embodiment 3

[0059] 1. Preparation and treatment of BC membrane

[0060] Gluconobacter xylinum was expanded and cultivated in the seed medium at 30°C for 24 hours according to the inoculation amount of 2 to 3 inoculation loops, and then transferred to the fermentation medium at 30°C according to the inoculum amount of 6% for static culture respectively 4, 7,10 days, harvest bacterial cellulose (BC) wet film; The prepared BC film is soaked in 0.5% NaOH solution in 100 ℃ of water baths until the BC film turns white and translucent, then the prepared BC film is compared with commercially available The antipyretic patch is cut into a rectangle with a diameter of 2cm×4.5cm for later use. The thickness of BC_4d is 1.64mm, the thickness of BC_7d is 2.68mm, the thickness of BC_10d is 3.38mm, and the thickness of commercially available antipyretic patch is 2.50mm;

[0061] Among them, both the seed medium and the fermentation medium are: mannitol, glucose, sucrose or fructose 2g, yeast extract 0.5g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com