Horizontal-array high-power semiconductor laser capable of replacing chip

A laser and high-power technology, applied in the direction of semiconductor lasers, semiconductor laser devices, lasers, etc., can solve the problems of laser output wavelength drift, long heat dissipation path, poor heat dissipation, etc., and achieve strong output wavelength selectivity and high power Requirements, improve the effect of wavelength consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention is described in further detail below in conjunction with accompanying drawing:

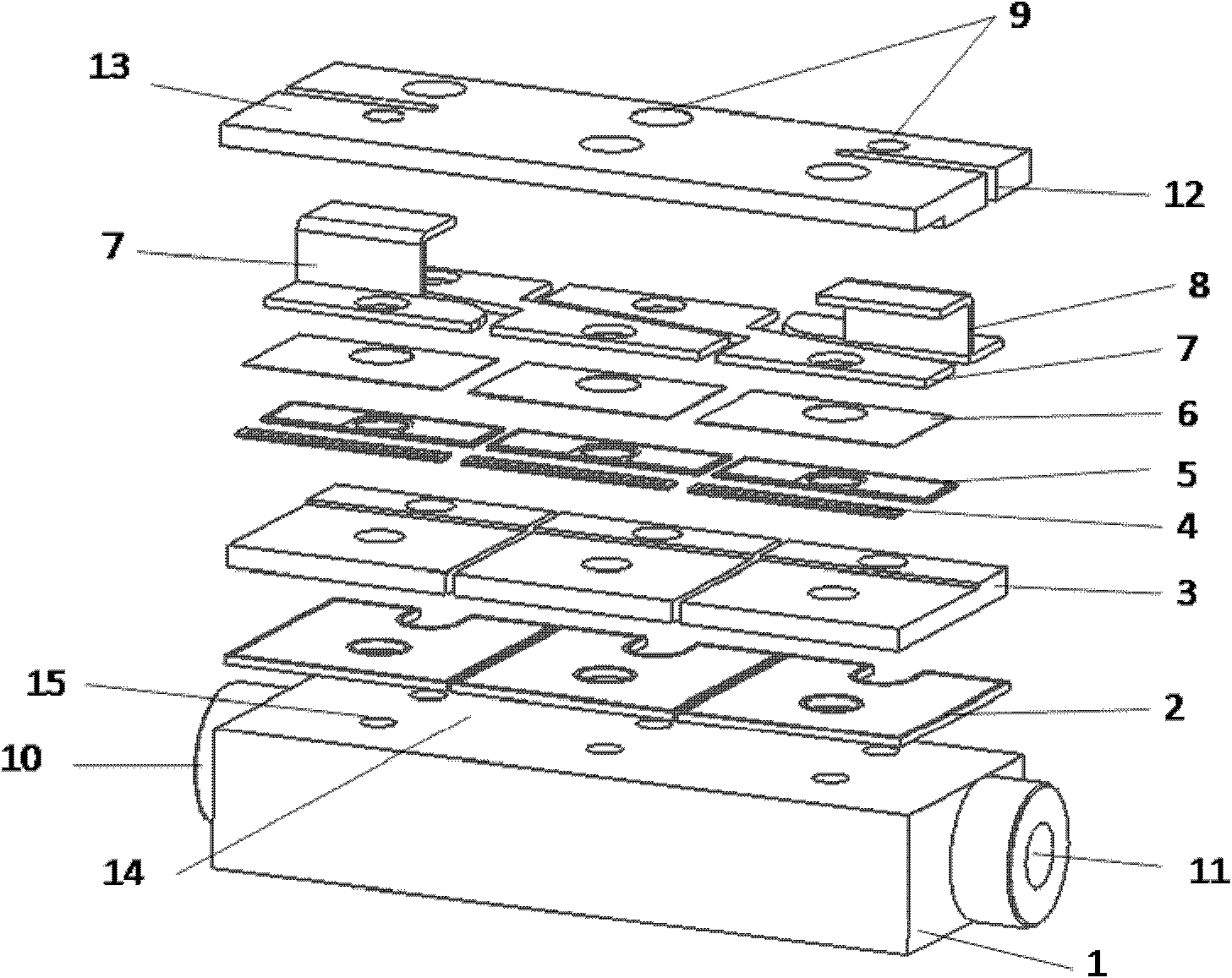

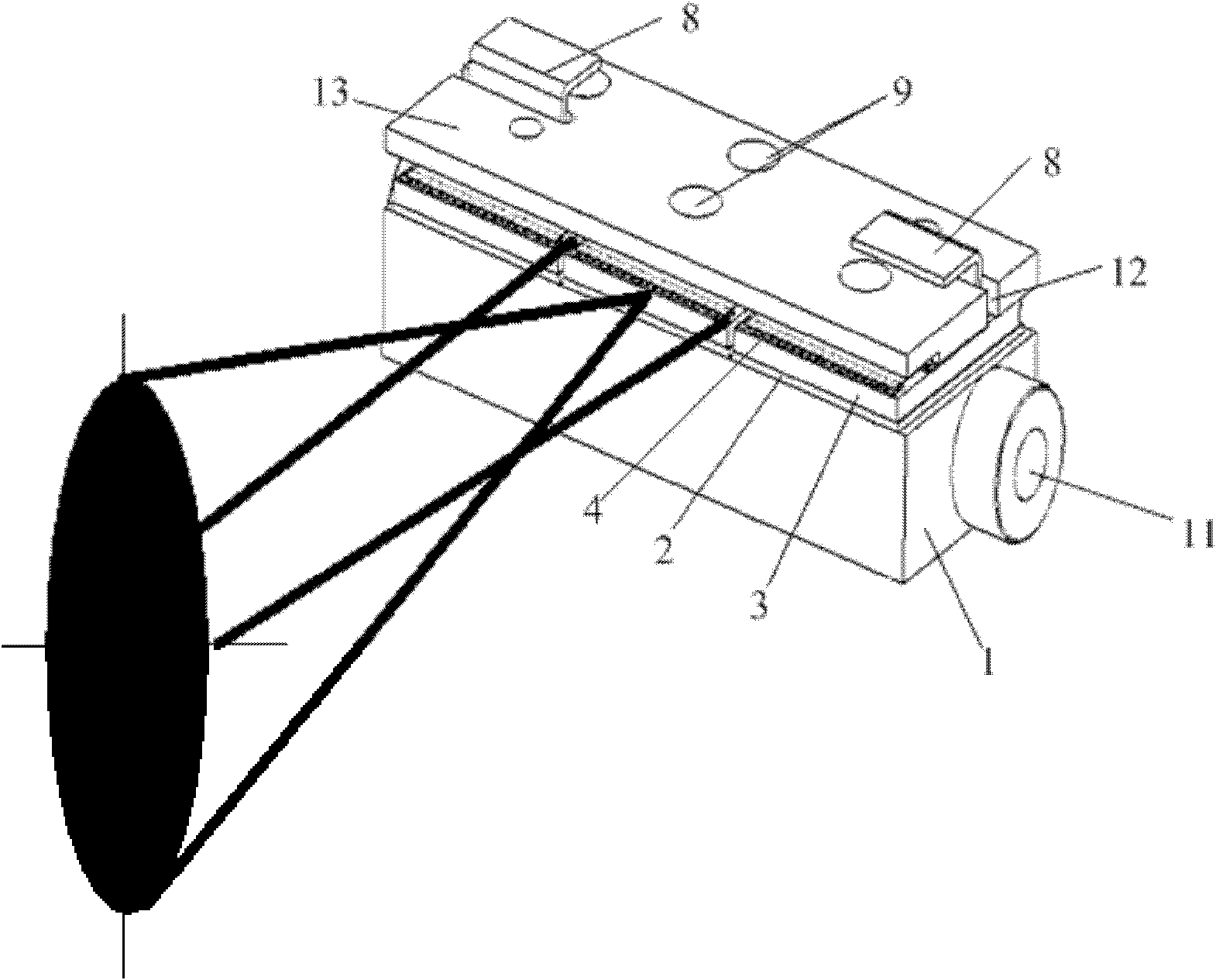

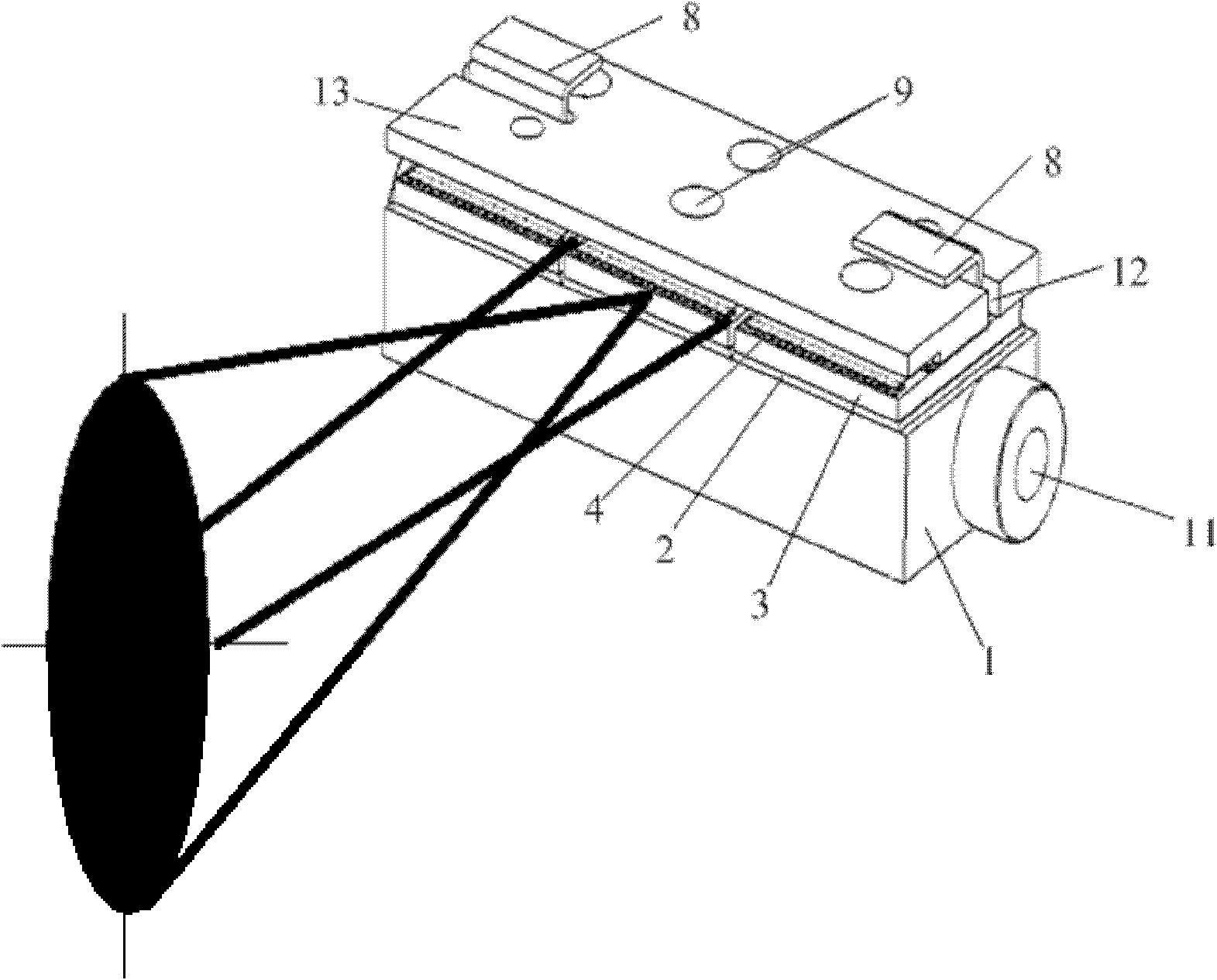

[0030] see figure 1 , the replaceable chip horizontal array high-power semiconductor laser of the present invention includes a refrigerator 1 made of a bar-shaped block, and the interior of the refrigerator 1 is provided with one or more parallel liquid channels in the axial direction, and the liquid channels are in the Both ends of the refrigerator 1 are provided with a refrigerator water inlet 11 and a refrigerator water outlet 10 respectively, and the cross-sectional shape of the liquid channel is rectangular, circular or elliptical. When multiple liquid passages are provided inside the refrigerator 1 , the multiple liquid passages may also share a set of water inlets and outlets, or multiple sets of water inlets and outlets may be provided at both ends of the refrigerator 1 . In order to improve the heat dissipation effect, the refrigerator 1 is made of materials ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com