Micro flow supply measuring device

A measuring device and flow rate technology, applied in mass flow measuring device, measuring device, liquid/fluid solid measurement, etc., can solve the problems of limited storage tank volume, low cost, large range, etc., achieve intuitive flow measurement, reduce errors, The effect of small external interference factors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

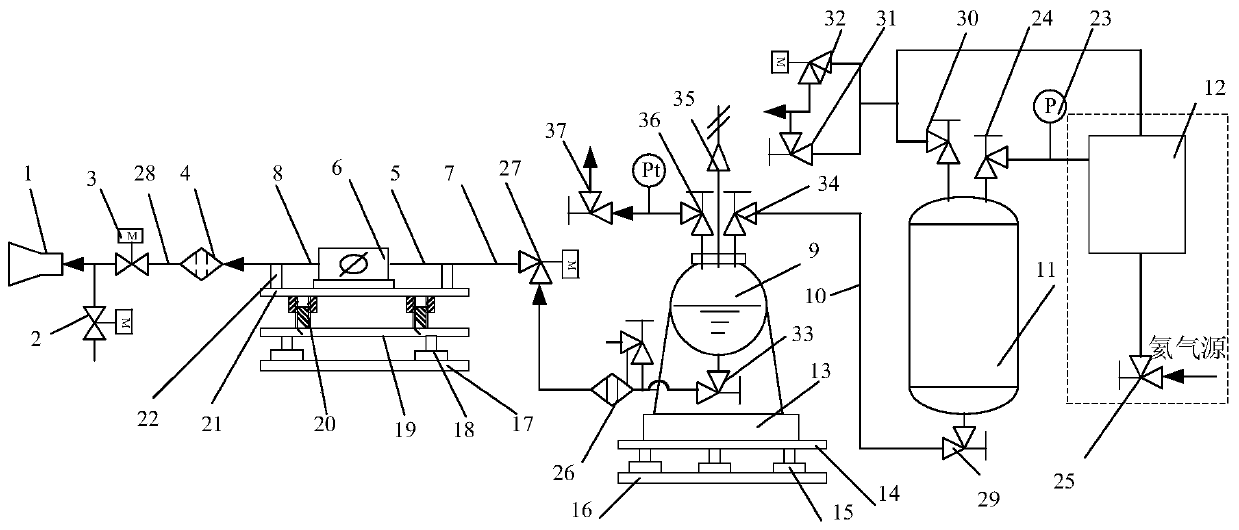

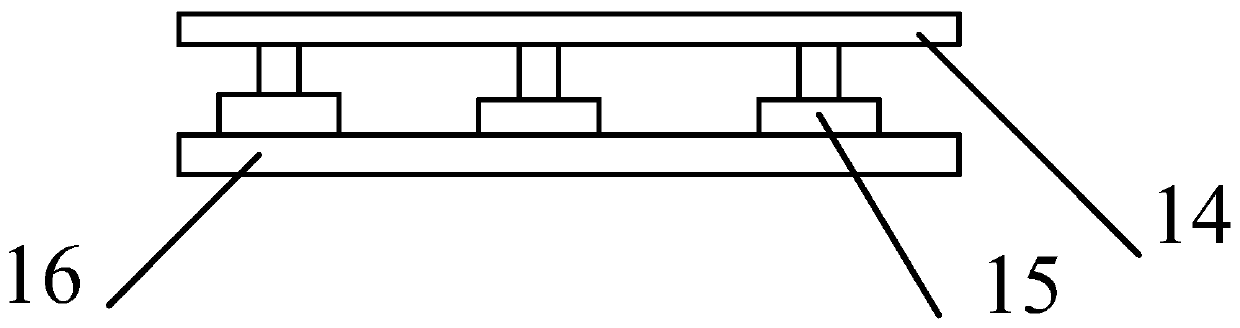

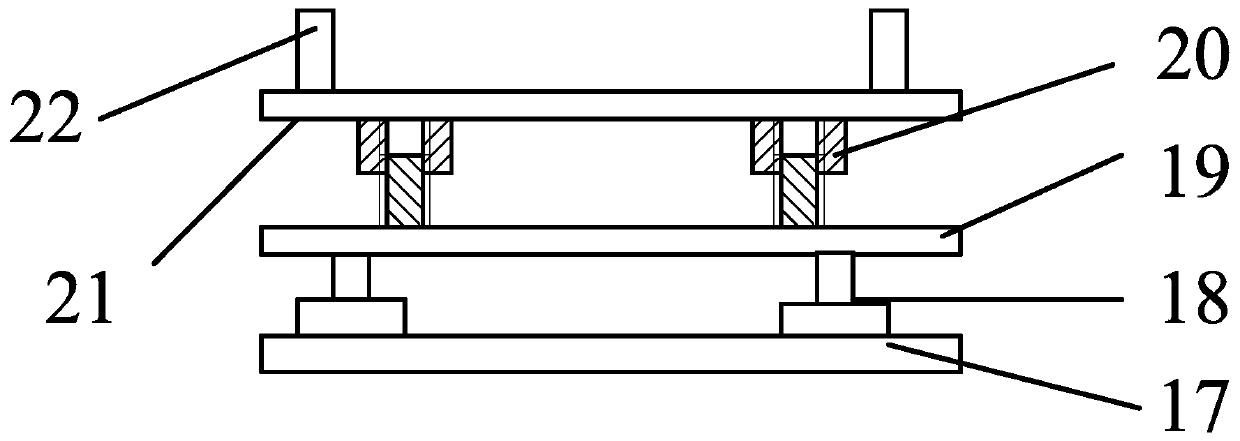

[0029] The content of the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0030] The invention provides a flow supply measuring device for a long-time test of an anhydrous hydrazine engine heated by a low-power electric arc. The device maintains the constant pressure and balances the pressure in the container through the automatic pressure regulating device, so as to realize the stable supply of small flow, and measures the flow data through the mass flow meter, and the data is easy to obtain intuitively; The isolation of flowmeter measurement accuracy interference factors ensures the accuracy of flowmeter measurement. At the same time, the flow measurement does not depend on the electronic scale, which reduces the requirement for the accuracy of the electronic scale, improves the storage capacity of the storage tank, and thus realizes the long-term supply ability.

[0031] Such as Figures...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com