Profiled inner pipe all-glass vacuum solar collector tube

An all-glass, heat-collecting tube technology, applied in solar collectors, solar thermal devices, solar thermal energy, etc., can solve the problem of low resistance to water pressure in the tube, resistance to axial bending, anti-sunburn and bursting, light-receiving surface area and heat transfer area Small, can not be fully utilized in time, etc., to achieve the effect of improving the resistance to water pressure in the pipe, improving thermal efficiency and effective heat utilization rate, and increasing strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Further explain in detail in conjunction with accompanying drawings;

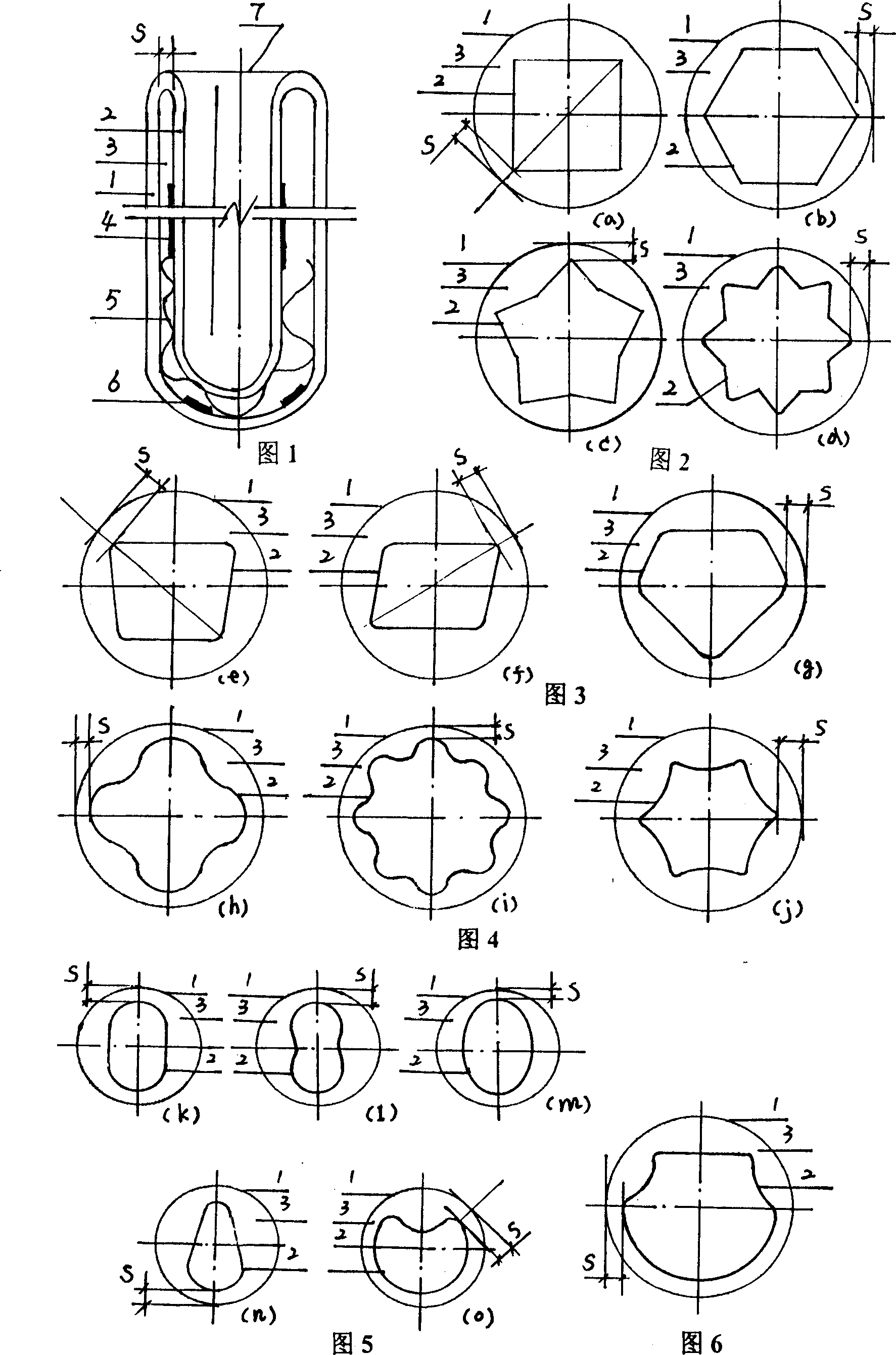

[0016] As shown in Figure 1, there is a vacuum chamber 3 between the outer pipe 1 and the inner pipe 2, the outer surface of the inner pipe 2 has an absorbing coating 4, the positioning steel bracket 5 of the inner pipe 2 is installed in the vacuum chamber 3, and there is The getter 6 has a connection opening 7 at the upper end; the wall of the inner tube 2 is in the shape of a polyhedron.

[0017] As shown in Figure 2, the face of the polyhedral cylinder that the wall of inner tube 2 is is plane, and the radial section of inner tube 2 is equilateral polygonal form, and the intersecting line of adjacent surface is arc transition; The number of faces is preferably more than four sides including four sides; the distance between the peak of the polyhedral cylinder and the inner wall of the outer tube 1 is S, and S must be greater than zero, generally 2 to 6mm. The radial section of the inner tube 2 It ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com