On-line high-precision fixed point side emitting type leak detection device and leak detection method for bag type dust remover

A bag-type dust collector, high-precision technology, applied in chemical instruments and methods, separation methods, application of light to test fluid tightness, etc., can solve problems such as online monitoring of difficult dust collectors, and achieve the goal of overcoming misjudgment and strong substitution Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

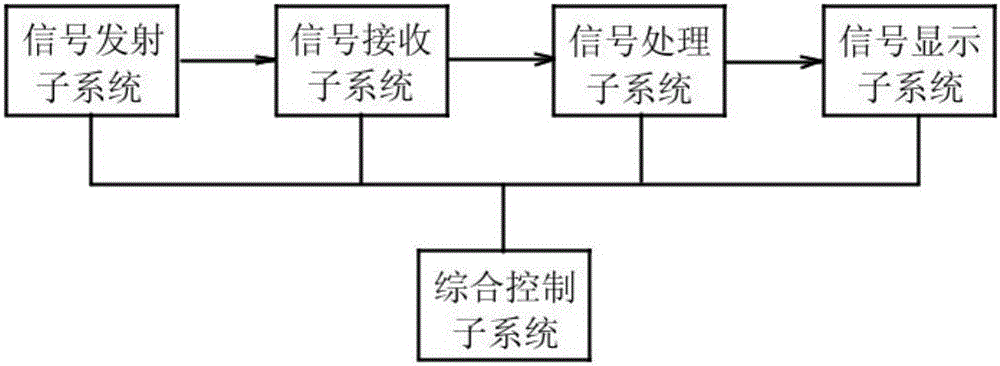

[0046] Such as figure 1 As shown, the bag filter (filter, dust collector) online high-precision fixed-point side-shooting type leak detection device of the present invention includes an optical signal transmitting subsystem, an optical signal receiving subsystem, a signal processing subsystem, and a signal display subsystem. system, and an integrated control subsystem, in which:

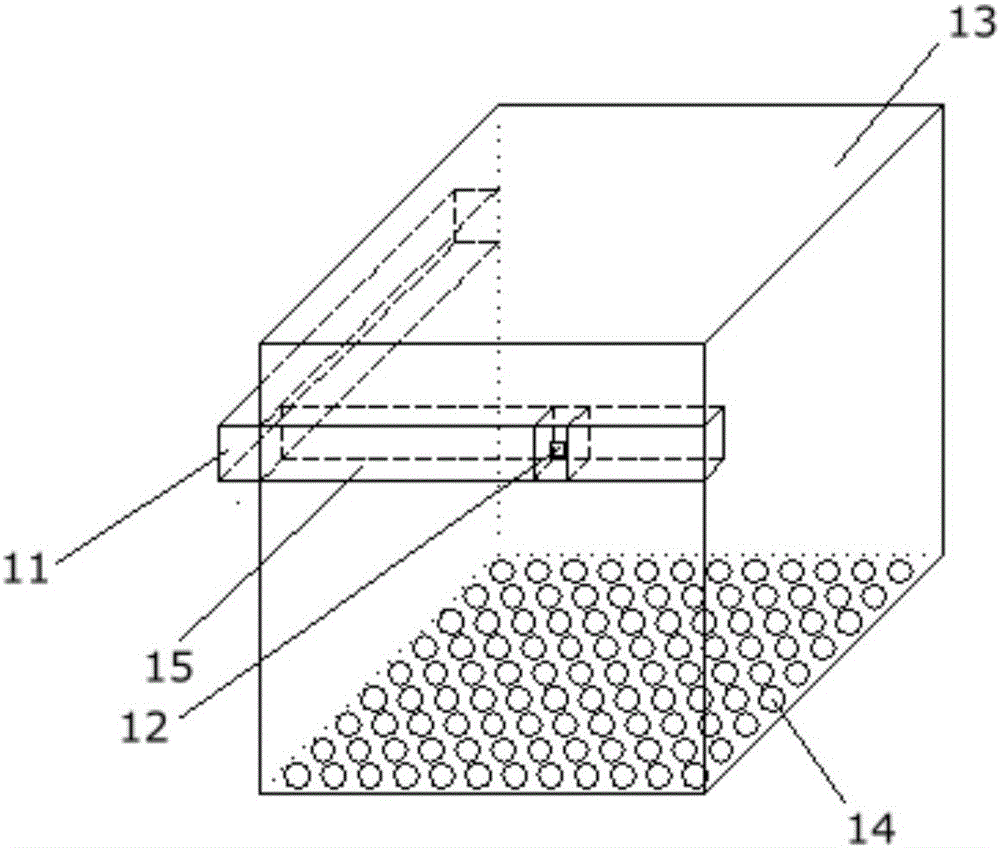

[0047] Such as figure 2 As shown, the optical signal transmitting subsystem 11 is installed on the side wall above the flower plate 14 (upper box) of the bag filter box 13 for sending out optical signals;

[0048] The optical signal receiving subsystem 12 is installed vertically on the adjacent side wall for receiving the optical signal sent by the optical signal transmitting subsystem 11;

[0049] The signal processing subsystem, signal display subsystem and signal control subsystem are all arranged outside the bag filter, wherein:

[0050] The signal processing subsystem is used to receive the ...

Embodiment 2

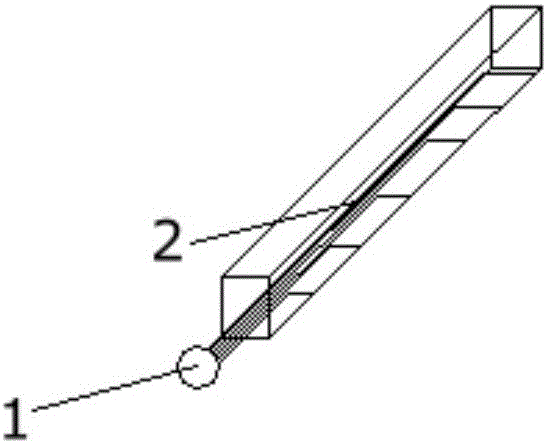

[0065] Such as image 3 Shown is the second embodiment of the bag filter (filter, dust collector) online high-precision fixed-point side-shooting type leak detection device of the present invention, and its difference from Embodiment 1 is: the signal transmitting subsystem 11 includes a light source 6 and an optical fiber 7 with an optional optical splitter, and the signal receiving subsystem 12 includes a sensor 8 and an optical fiber 9 with an optional optical splitter; the light source 6 uses near-infrared light.

[0066] When detecting the first row, the near-infrared light emitted by the light source 6 passes through the optional beam splitter to select the first row, and the light is totally reflected to the first row through the optical fiber 7, and emits near-infrared light, which is received by the sensor 8 of the corresponding optical fiber 9 Near-infrared light; when the second row is detected, the optical splitter selects the second row to open the optical path, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| dust removal efficiency | aaaaa | aaaaa |

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com