Method for simultaneously measuring heavy metals with different forms in coal-fired flue gas

A coal-burning flue gas and heavy metal technology, which is applied in the preparation of test samples, measuring devices, sampling devices, etc., can solve the problems of inability to distinguish different forms, cumbersome operations, and heavy workload, so as to reduce labor and large consumption of reagents , Improve the analysis accuracy, the effect of reliable data support

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

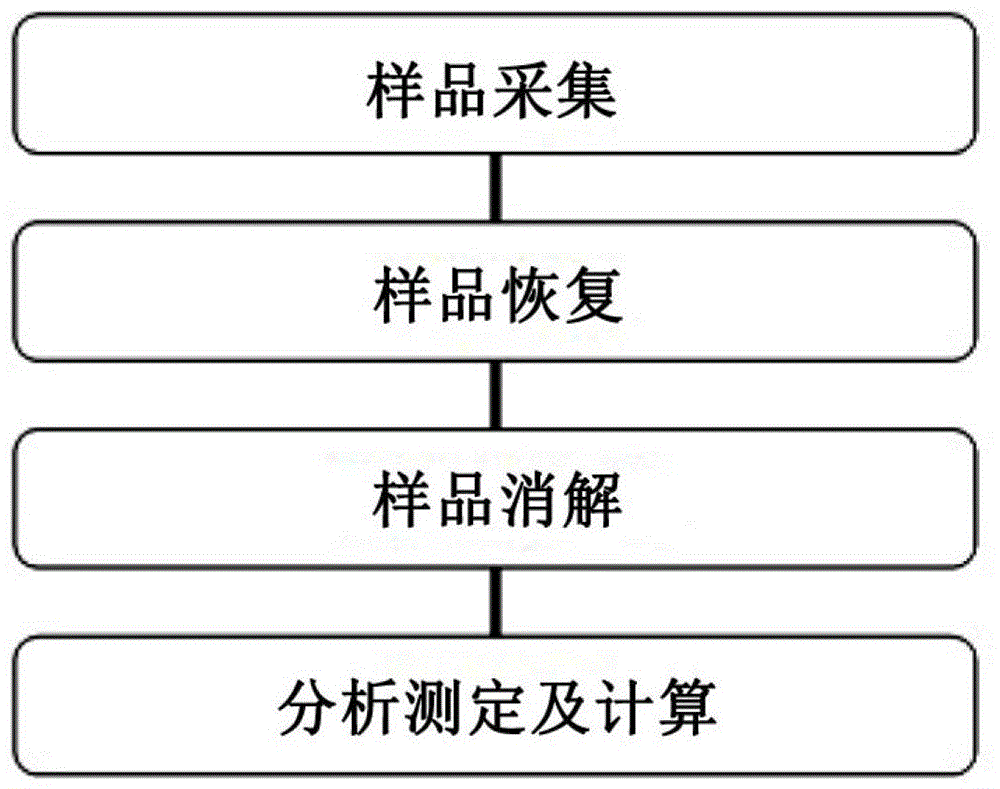

Method used

Image

Examples

Embodiment 1

[0045] At present, most coal-fired power plants in my country have installed flue gas purification devices such as desulfurization and dust removal or denitrification. The composition of flue gas in different locations is different, which may affect the concentration of heavy metals in flue gas. Therefore, choose different locations of typical power plants in my country to burn coal Experimental study of flue gas.

[0046] 1. Sample collection

[0047] A. Preparation before sampling

[0048] Weigh several 200 to 300 g portions of silica gel to the nearest 0.5 g in an airtight container. Record the total weight of the silica gel plus the container on each container; alternatively, weigh the silica gel directly in the 8 Absorber Vial immediately prior to assembling the sample collection system components.

[0049] Dry the filter holder at a temperature of 20 ± 5.6°C (68 ± 10°F) and ambient pressure for 24 to 36 h, weigh at least every 6 h until constant weight, and record the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com