Method for generating hydrogen through lithium borohydride-porous carbon hydrolysis and reaction system

A lithium borohydride and hydrolysis reaction technology, applied in the field of LiBH4 hydrolysis hydrogen production materials and its hydrolysis reaction device, can solve the problems of fast and uncontrollable hydrogen generation speed, and achieve beneficial performance, small size, and high hydrogen release efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

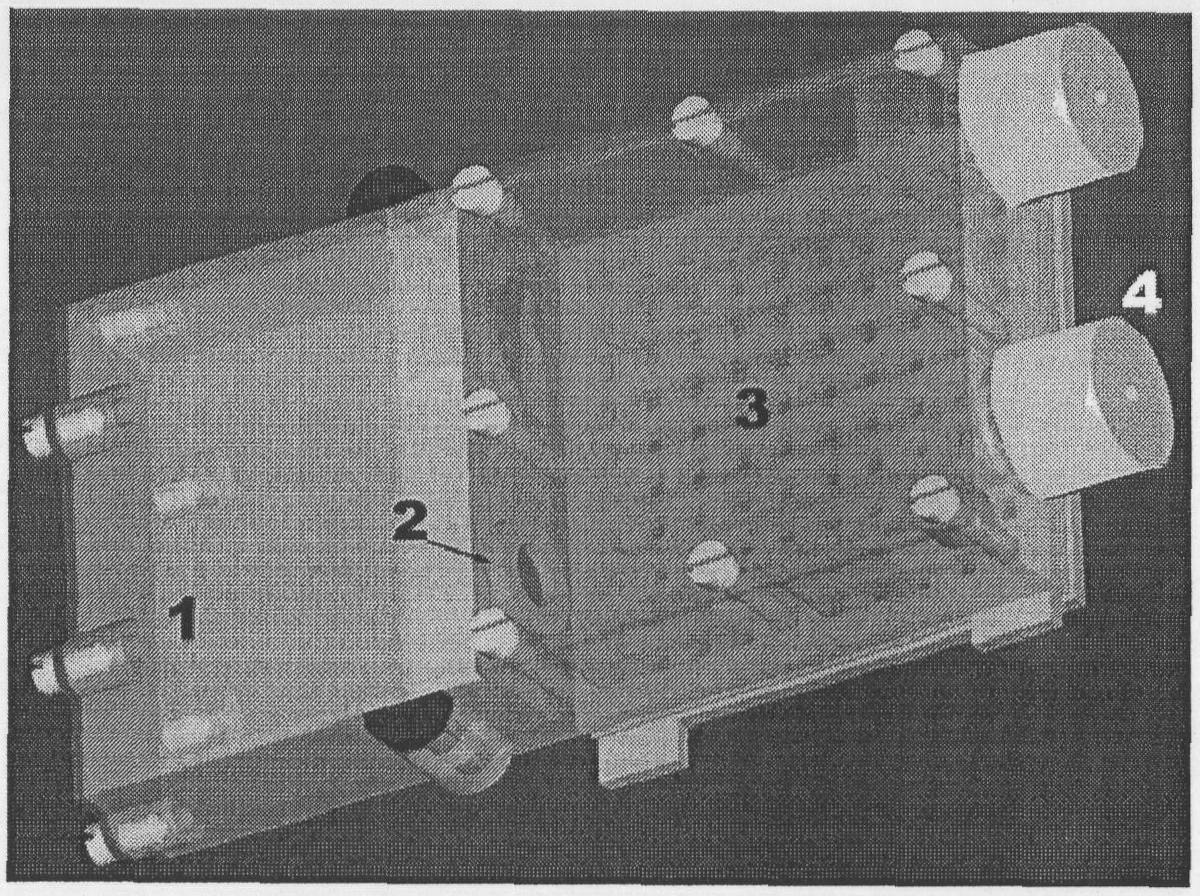

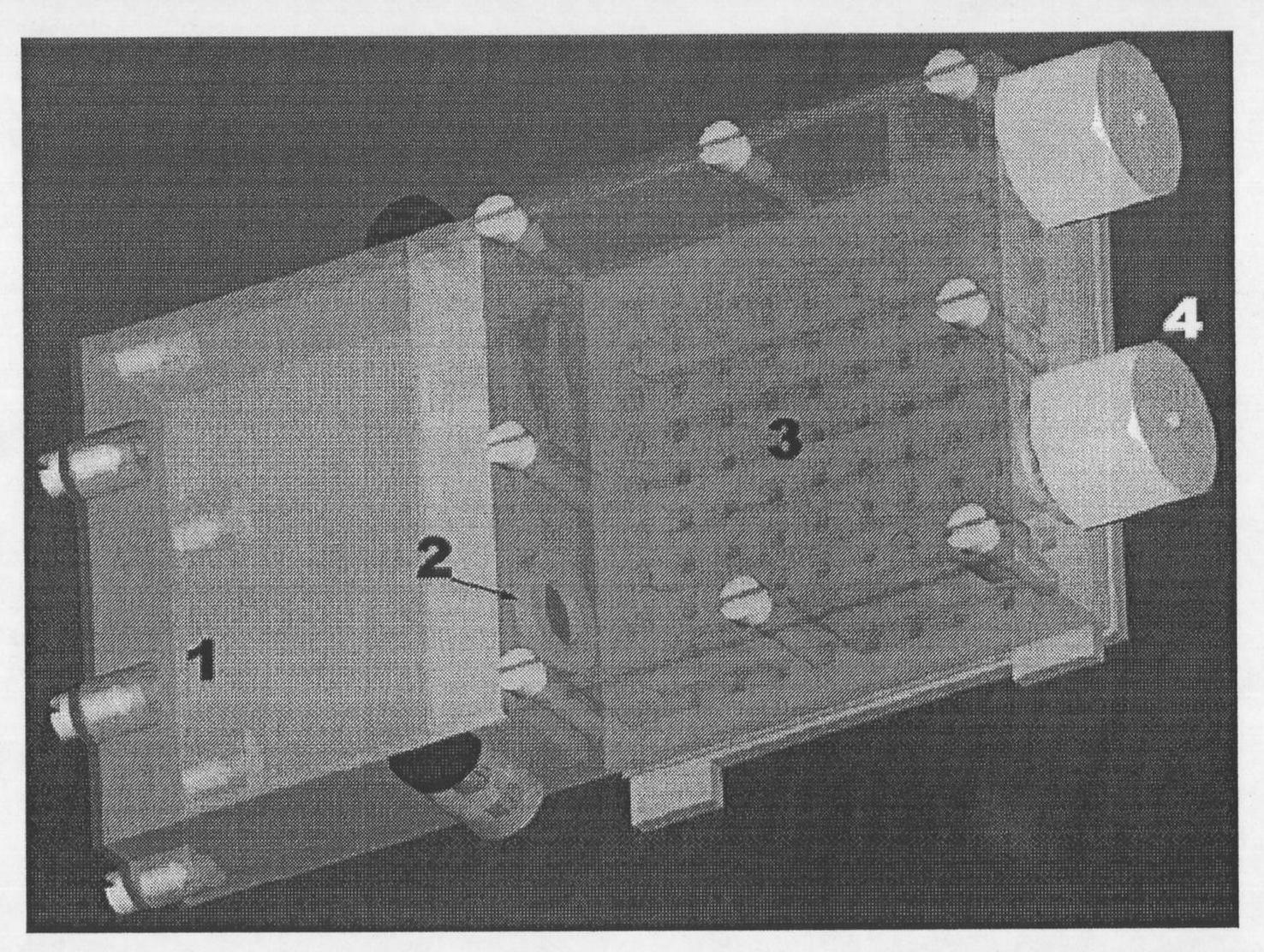

[0027] 93wt%LiBH 4 and 7wt% single-walled carbon nanotubes, 0.1g in total, put into a ball mill jar, and ball mill for 30 minutes at a speed of 100rpm. After taking it out, put it into figure 1 In the hydrolysis reaction chamber of the hydrolysis reaction system, first open the gas outlet valve 4 to connect with the micro fuel cell, then open the water inlet valve 2, and inject 4.48 μL / min liquid water into the hydrolysis reaction chamber through the micro pump, the rate of hydrogen generated by the system is The temperature is 10ml / min, and the temperature of hydrogen is 95°C.

Embodiment 2

[0029] 93wt%LiBH 4 and 7wt% single-walled carbon nanotubes, 0.1g in total, put into a ball mill jar, and ball mill for 30 minutes at a speed of 150rpm. After taking it out, put it into figure 1 In the hydrolysis reaction chamber of the reaction system shown in the hydrolysis, first open the gas outlet valve 4 to connect with the micro fuel cell, then open the water inlet valve, inject 0.48ml / min liquid water into the device through the micro pump, the rate of hydrogen produced by the system is 100ml / min, and the temperature of hydrogen is 95°C.

Embodiment 3

[0031] 93wt%LiBH 4and a total of 0.7g of 7wt% carbon nanotubes, put into a ball mill jar, and ball mill for 60 minutes at a speed of 100rpm. After taking it out, put it into figure 1 In the hydrolysis reaction chamber of the reaction system shown, first open the outlet valve to connect with the micro fuel cell, then open the water inlet valve, inject 0.48ml / min liquid water into the device through the micro pump, and the rate of hydrogen generated by the system is 100ml / min, the temperature of hydrogen is 90°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com