Reduction gear for natural energy recovery system

A technology of recovery system and reduction gear, applied in the direction of transmission, transmission parts, gear transmission, etc., can solve the problems of damage of the third reduction mechanism 530, etc., and achieve the effect of increasing impact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

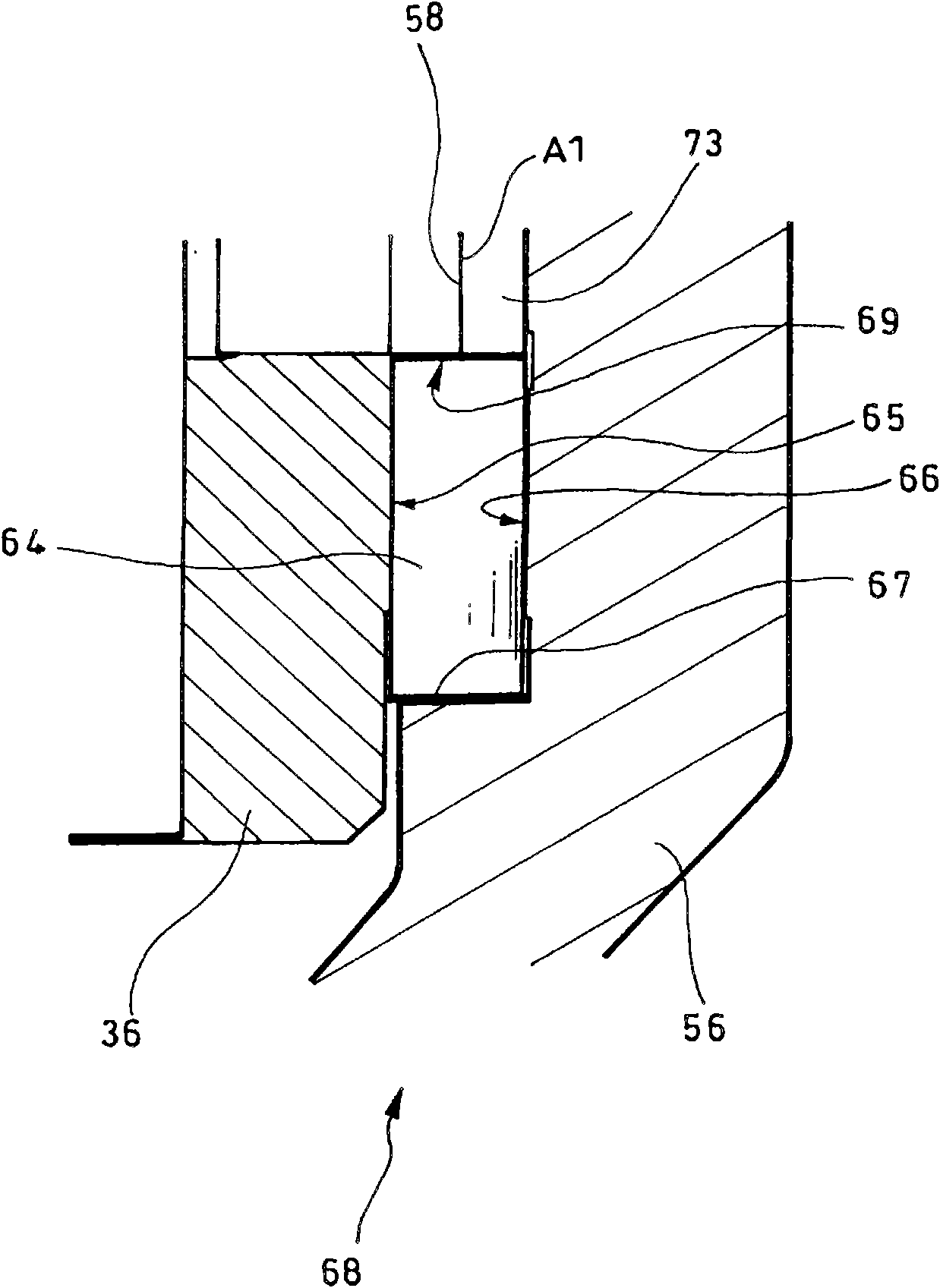

[0023] In order to clarify the use of the reduction gear G1, for convenience, first, a yaw drive device for a wind power generator, which is an example of a natural energy recovery system, will be described. The yaw drive is shown in Figure 6 , Figure 7 .

[0024] In this embodiment, the present invention is applied to the speed reduction device G1 of the yaw drive device 14 . The yaw driving device 14 includes an electric motor Mo, a reduction gear G1 with an output pinion 24 , and a revolving internal gear 28 meshing with the output pinion 24 . Figure 7 In the example of , four reduction gears G1 are depicted, which are respectively fixed on the main body side of the power generating unit 12 . On the other hand, each output pinion 24 of the four reduction gears G1 (refer to figure 1 ) is fixed to the side of the cylindrical support 11, and constitutes an inner ring of a yaw bearing not shown. The outer ring (not shown) of the yaw bearing is fixed to the main body si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com