Method for preparing titania film by using gas flow reaction sputtering under middle gas pressure and method for preparing solar cell

A solar cell and titanium dioxide technology, which is applied in sputtering plating, ion implantation plating, metal material coating process, etc., can solve the problem of poor process repeatability and difficulty in obtaining stable and high-quality transparent conductive titanium dioxide film, etc. Problems, achieve the effect of reducing crystal defects, increasing the probability of collision, and improving conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described below in conjunction with accompanying drawing and embodiment:

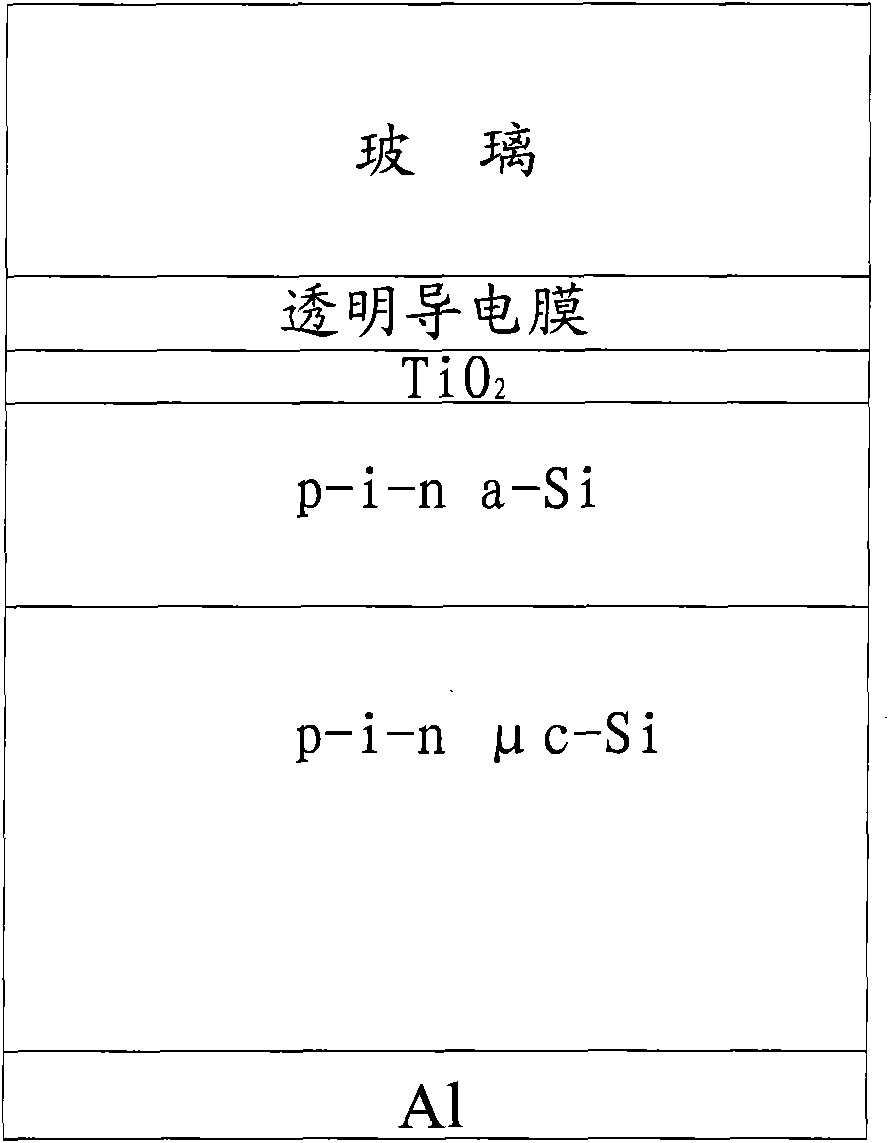

[0036] The invention discloses a method for preparing titanium dioxide nano-films by using medium-pressure gas flow reaction sputtering, which uses a hollow cathode and high-flow high-speed argon to prevent the reaction gas from contacting the target surface and increase the pressure of the working gas in the sputtering reaction. This is achieved by reducing the energy of the particles. Therefore, when oxygen ions and neutral particles hit the substrate, they will not affect the TiO 2 film growth.

[0037] Specifically, it includes the following steps:

[0038] A), the glass substrate that is coated with transparent conductive film is put into the reaction chamber of vacuum sputter coating equipment, and the vacuum degree of reaction chamber is pumped to 10 -1 Pa, usually the transparent conductive film is SnO 2 or ZnO or InSnO thin film;

[0039]B), the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com