Method for preparing bacillus subtilis lipopeptid biosurfactant

A Bacillus subtilis and biological surface technology, which is applied in the field of producing lipopeptide biosurfactant Surfactin, can solve the problems of low yield and can not reach commercial use, etc., and achieves the effects of efficient production and simple fermentation process operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

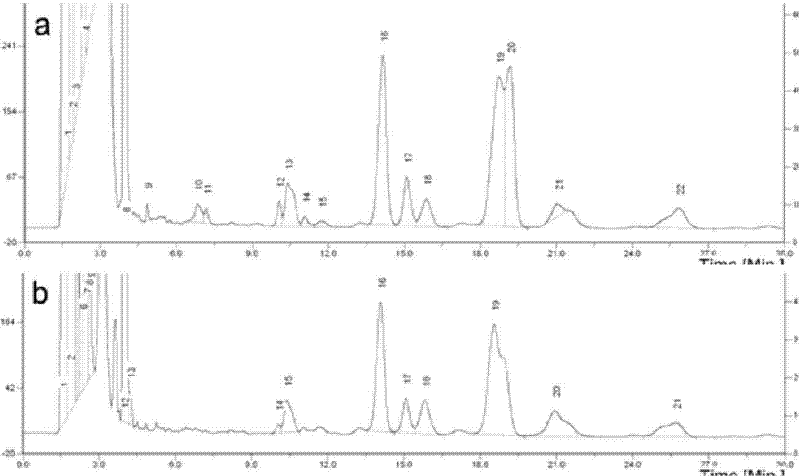

Embodiment 1

[0028] Take the strains BIT09S1, BIT09S2 and BIT09A2 preserved on the slant, inoculate them into 25mL / 250mL LB medium and cultivate them at 37°C for 36h; the obtained seed solution is inoculated into fermentation medium according to 5% inoculation amount: maltose (6.7%), soybean powder (4%), K 2 HPO 4 (0.5%), MgSO 4 ·7H 2 O (0.05%), CaCl 2 2H 2 O (0.018%), FeSO 4 ·7H 2 O(25ppm), MnCl 2 4H 2 O (22ppm), yeast powder (0.1%), water, pH 7.0, loading volume 100mL / 250mL, culture at 37°C for 72h. After the cultivation, take 40mL of the fermentation broth and centrifuge at 8000r / min for 10min to remove the bacteria. The obtained supernatant is used for the measurement of the surface tension. Acid precipitation. Dry at 60°C for 24 hours, take it out and add 0.6mL methanol to dissolve it, sonicate for 1 hour, take the supernatant and save it for HPLC analysis. The mensuration of surface tension first records the density of fermented liquid supernatant, measures the surface tens...

Embodiment 2

[0033] Take the strains preserved on the slant: BIT09S1, BIT09S2 and BIT09A2, inoculate them in 25mL / 250mL LB medium respectively, and cultivate them at 200rpm at 37°C for 36h. NH 4 NO 3 (0.2%), K 2 HPO 4 ·3H 2 O (0.3%), NaH 2 PO 4 2H 2 O (1%), MgSO 4 ·7H 2 O (0.02%), MnCl 2 4H 2 O (2ppm), yeast powder (0.02%), water, pH 7.2, cultured at 150rpm at 28°C for 72h. After the cultivation, take 30mL of the fermentation broth and centrifuge at 8000r / min for 10min to remove the bacteria. The obtained supernatant is used for the measurement of surface tension. After the measurement, adjust the pH to 2.0 with 6mol / L HCl, put it in the refrigerator at 4°C overnight, and centrifuge to obtain the acid precipitate. .Dry at 60°C for 24 hours, take it out and add 0.6mL of methanol to dissolve it, sonicate for 1 hour, take the supernatant and save it for HPLC analysis. The analysis of surface tension measures the density of fermented liquid supernatant earlier, then measures the su...

Embodiment 3

[0038] Get the bacterial strain BIT09S1 that slant preserves, inoculate in the LB medium of loading capacity 25mL / 250mL, cultivate 36h at 37 ℃ 200rpm, gained seed liquid is inoculated in fermentation medium by 5% inoculum size: guar gum gel breaker (20g guar Glue Enzyme GLZ-1 biological enzyme gel breaker), 0.5% NH 4 h 2 PO 4 , 0.3% (NH 4 ) 2 HPO 4 , K 2 HPO 4 ·3H 2 O (0.3%), MgSO 4 ·7H 2 O (0.02%), MnCl 2 4H 2O (2ppm), yeast extract (0.02%), water, pH 7.2, cultured at 37°C for 72h. After the cultivation, take 25 mL of the fermentation broth, centrifuge at 8000r / min for 10min to remove the bacteria, and the obtained supernatant is used for the measurement of the surface tension. Acid precipitation. Dry at 60°C for 24 hours, take it out and add 0.6mL methanol to dissolve it, sonicate for 1 hour, take the supernatant and save it for HPLC analysis. The measurement of surface tension first measures the density of the supernatant of the fermentation broth, and then...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com