Method for preparing 2,2,4-trimethyl-1,3-pentanediol single-isobutyrate

A technology of pentanediol monoisobutyrate and trimethyl, which is applied in the field of organic chemical industry, can solve the problems of non-conformity with the concept of green environmental protection, highly toxic substances, and large equipment corrosion, so as to achieve easy separation and recovery, and low equipment corrosion , the effect of simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] (1), preparation of KF / MgO catalyst

[0021] Step 1 Vector Pretreatment

[0022] 50g of MgAc 2 , in a muffle furnace at 500 ° C, under an air atmosphere, calcined for 5 hours under a temperature-programmed condition, and then cooled to room temperature and taken out to obtain MgO powder.

[0023] Step 2 Solid Phase Grinding

[0024] Take 6g MgO powder and a certain amount of KF·2H 2 O (the mass of converted KF is 30% of MgO), grind and mix in a mortar for 30min.

[0025] Step 3 Dry

[0026] Dry the KF / MgO obtained in the second step in an oven at 80° C. for 12 h. After cooling to room temperature, the catalyst KF / MgO-80 is obtained.

[0027] Step 4 Catalyst Treatment

[0028] Put the KF / MgO-80 obtained in the third step in a muffle furnace, and calcinate it under air atmosphere at 500°C for 5 hours under a temperature-programmed condition, then cool to room temperature and take it out to obtain the catalyst KF / MgO-500.

[0029] Other catalysts such as K 2 CO 3...

Embodiment 2

[0039] a, with stirring, in the 100mL tank reactor of condensing system and thermometer, add 30g of 2% NaOH solution, in N 2 Under the condition of protection and stirring, 30g of isobutyraldehyde was slowly added dropwise, and the aldol condensation reaction was carried out at 30°C; the reaction was stopped, washed with water, left standing for 8h, liquid separation, and the oil layer and the water layer were separated.

[0040] b, put the separated oil layer in a in N 2 Under protection, heat up to 90°C, add KF / γ-Al whose weight is 3% of oil layer weight 2 o 3 , magnetic stirring, continue to react 10h.

[0041] c., settle the reaction mixture obtained in b, filter and separate the catalyst, and distill the filtrate under reduced pressure to obtain the product 2,2,4-trimethyl-1,3-pentanediol monoisobutyrate, the product Yield = 50.8% by GC analysis.

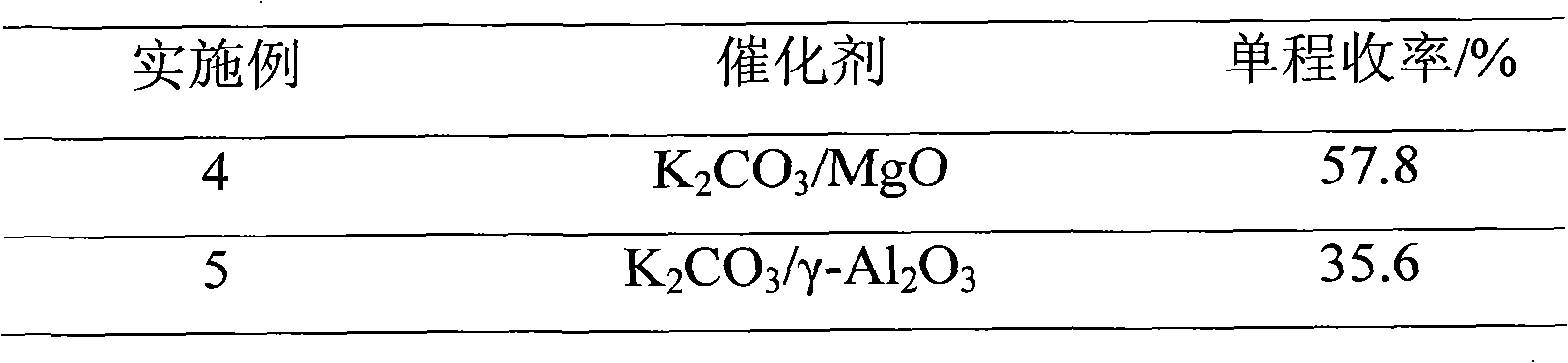

Embodiment 4-5

[0043] with K 2 CO 3 / MgO, K 2 CO 3 / γ-Al 2 o 3 Be catalyzer, other conditions are identical with embodiment 1, and reaction result is as follows:

[0044]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com