Production method of cellosilk enhanced compound hollow fiber membrane

A technology for enhancing compounding and manufacturing methods, applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc., can solve the problems of weak interface binding force, poor hydrophilicity, easy pollution, etc. Strong stain resistance and reproducible results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

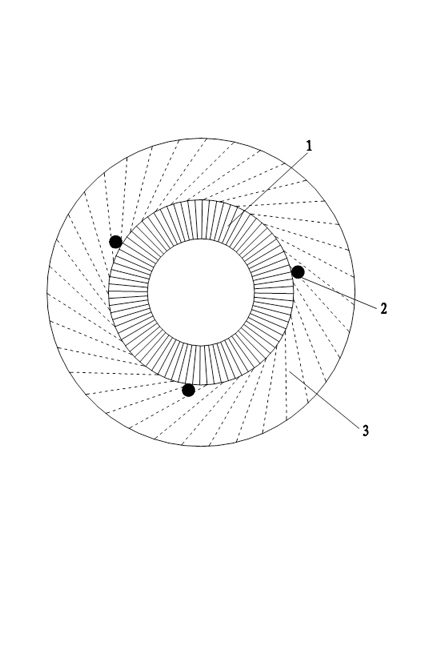

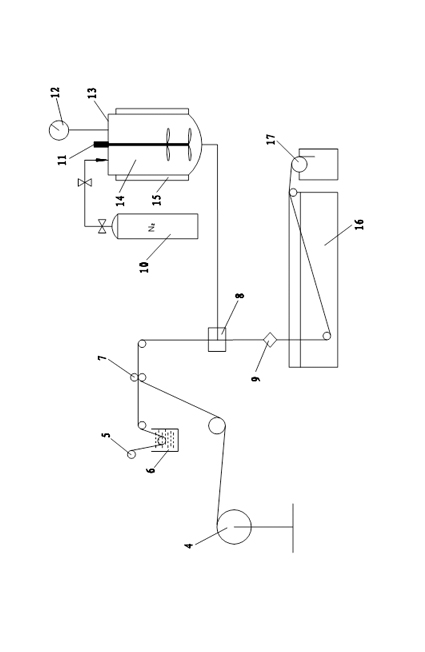

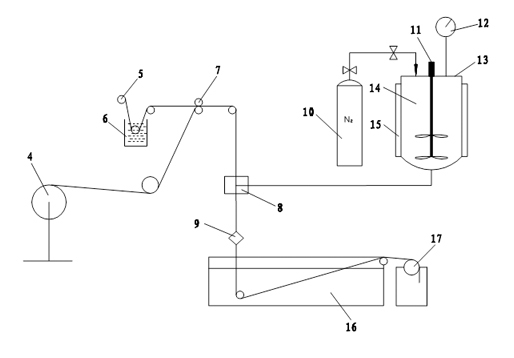

[0056] Example 1: See figure 1 and figure 2 , 7 kg of dimethylacetamide, 2 kg of polyethersulfone polymer, 0.5 kg of polyethylene glycol, and 100 g of lithium chloride were stirred and dissolved evenly to make a fiber filament reinforced composite hollow fiber membrane inner membrane casting solution , using the dry-wet hollow fiber spinning process, the casting liquid and the core liquid (the core liquid is pure water) are extruded through the spinning head, passed through the external coagulation bath water tank (the coagulant is pure water), and drawn in the winding On the wheel, the inner layer membrane 1 of the fiber reinforced composite hollow fiber membrane is formed. Stir and dissolve 100 grams of polyurethane and 900 grams of dimethylformamide evenly to prepare a bonding solution for fiber reinforced composite hollow fiber membranes. 7 kg of dimethylacetamide, 2 kg of PVDF polymer, 0.5 kg of polyethylene glycol, 100 g of lithium chloride, and 100 g of Tween-80 were...

Embodiment 2

[0057] Example 2: 7 kilograms of dimethylacetamide, 2 kilograms of polyethersulfone polymer, 0.5 kilogram of polyethylene glycol, and 100 grams of lithium nitrate were stirred and dissolved evenly to make a fiber filament reinforced composite hollow fiber membrane inner membrane casting Membrane liquid, using dry-wet hollow fiber spinning process, the casting liquid and core liquid (the core liquid is pure water) are extruded through the spinning head, and the external coagulation bath tank (the coagulant is pure water) is drawn in the On the winding wheel, the inner membrane of the fiber reinforced composite hollow fiber membrane is formed. Stir and dissolve 100 grams of polyurethane and 900 grams of dimethylformamide evenly to prepare a bonding solution for fiber reinforced composite hollow fiber membranes. Mix 7 kg of dimethylacetamide, 2 kg of PVDF polymer, 0.5 kg of polyvinylpyrrolidone, 100 g of lithium chloride, 100 g of Tween-80, and 100 g of Span-80, stir and dissolve...

Embodiment 3

[0058] Example 3: 7 kilograms of dimethylacetamide, 2 kilograms of polyethersulfone polymer, 0.5 kilogram of polyethylene glycol, and 100 grams of lithium chloride were stirred and dissolved evenly, and the inner layer membrane of the fiber reinforced composite hollow fiber membrane was made Casting liquid, using dry-wet hollow fiber spinning process, the casting liquid and core liquid (core liquid is pure water) are extruded through the spinning head, passed through the external coagulation bath (coagulant is pure water), and drawn On the winding wheel, the inner layer of the fiber reinforced composite hollow fiber membrane is formed. Stir and dissolve 100 grams of polyurethane and 900 grams of dimethylformamide evenly to prepare a bonding solution for fiber reinforced composite hollow fiber membranes. 7 kg of dimethylacetamide, 2 kg of PVDF polymer, 0.5 kg of polyethylene glycol, 100 g of lithium chloride, and 400 g of Tween-80 were stirred and dissolved evenly to form the o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Separation aperture | aaaaa | aaaaa |

| Porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com