Fat blend for heat-resistant chocolate

A chocolate and mixture technology, applied in the fields of application, food science, cocoa, etc., can solve the problems of easy blooming and unsatisfactory effect of CBS fat.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

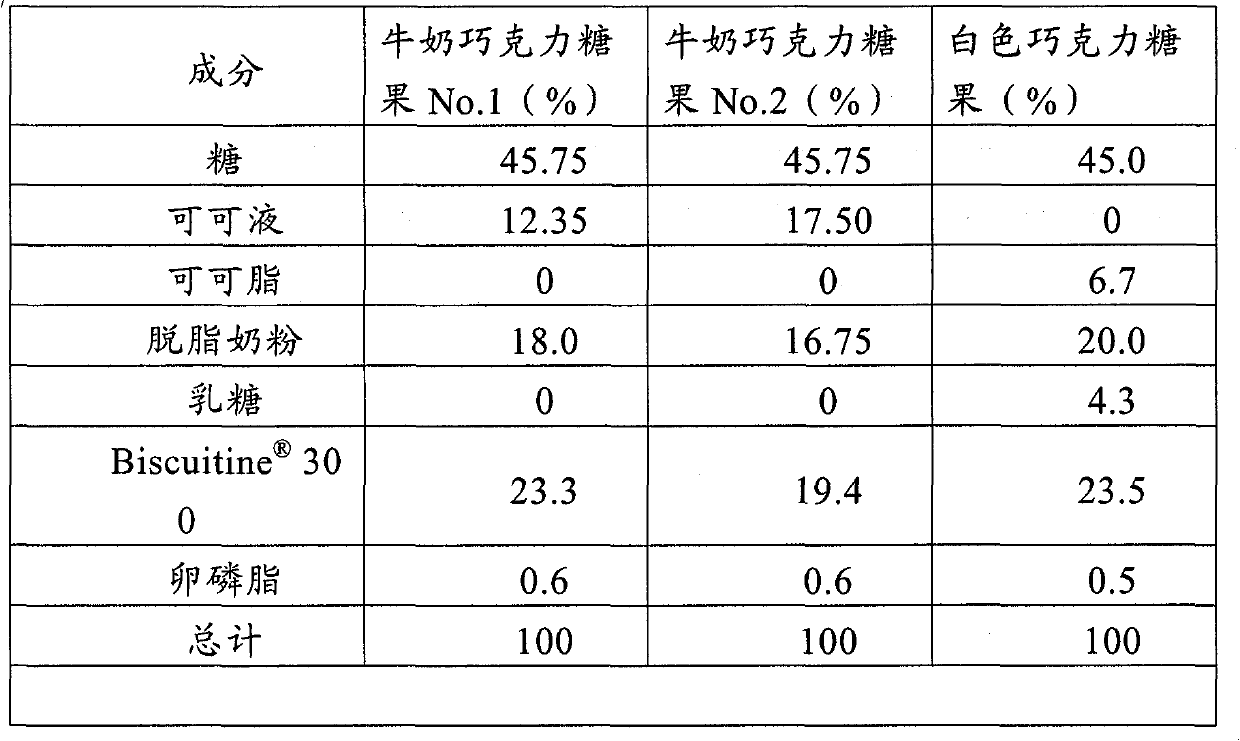

[0075] Example 1. Chocolate base with baking fat. The ingredients for the "milk" No. 1 and No. 2 and "white" type chocolate bonbons were mixed and refined according to Table 1. In double jacket mixer ( Mixer, Hameln, Germany) at 50 ° C (15 minutes, 1000 rpm) to mix all ingredients (except lecithin and a part 300); the total fat content is 24%. Refined to a particle size of d90 < 30 microns using a pilot scale three roll refiner (laser diffraction, Malvern). The base was kneaded with a pilot scale chocolate mixer kneader with a capacity of 60 kg. Add lecithin and the rest of the liquid fat during stirring and kneading. Prepare the following samples:

[0076]

[0077]

[0078] An example of calculating the cocoa butter to liquid fat ratio is provided in the table below using a 100 gram sample of milk chocolate candy No. 1. This calculation requires summing the entire composition to determine the total fat from the cocoa butter component and the total fat from the li...

Embodiment 2

[0081] Example 2. This example illustrates the manufacture of heat resistant chocolate chips. Preparation contains 5.88% cocoa butter and 20.52% 300, 70.6% sorbitol solution (ie 30% moisture content ) and 3.1% PGPR (polyglycerol-polyricinoleate (E 476)) water-in-oil emulsion. The emulsion was mixed with tempered chocolate at a ratio of 9.7% emulsion to 90.3% chocolate. Approximately 100 grams of this mixture was poured into sheet molds and processed on a vibrating table until the mass was evenly distributed. Prior to cooling, the mold was placed in a conventional 3.3 kilowatt microwave oven for 50 seconds to provide heat resistance to the chocolate chips. After sufficient cooling (eg, 20 minutes at 5-10° C.), the sheets are demolded and packaged.

[0082] The heat resistant chocolate chips had a weight ratio of cocoa butter to liquid fat of 22:78. The tablet passed the high temperature anti-frost test; the flavor was advantageously comparable to conventional chocolate. ...

Embodiment 3

[0083] Example 3. This example illustrates a milk chocolate product using skim milk powder as liquid fat with two different cocoa / liquid fat ratios. The composition of these samples is given in the table below:

[0084]

[0085] Combine all ingredients except lecithin, part of the milk fat, PGPR and Sorbidex in a double jacket mixer ( Mixer, Hameln, Germany) at 50° C. (15 minutes, 1000 rpm). Refined to a particle size of d90 < 30 microns using a pilot scale three roll refiner (laser diffraction, Malvern). The base was kneaded with a pilot scale chocolate mixer kneader (60 kg capacity). Add lecithin and remaining fat during stirring and kneading. To make the HRC, PGPR (0.2%, at room temperature) and Sorbidex (7%, at room temperature) were gradually and manually mixed with the base at 50°C. The mixture is then deposited in a mold, followed by microwave treatment under conditions sufficient to provide a product surface temperature of 80 to 95°C and the desired heat resist...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com