Evaporation chamber of vacuum hot water boiler

A hot water boiler and evaporation chamber technology, applied in fluid heaters, lighting and heating equipment, etc., can solve the problems of affecting the heat exchange efficiency of vacuum hot water boilers, affecting the efficiency of vacuum hot water boilers, hindering the rise of water vapor, etc. The effect of overcoming the phenomenon of water vapor eddy current, improving the exchange efficiency and increasing the flow rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

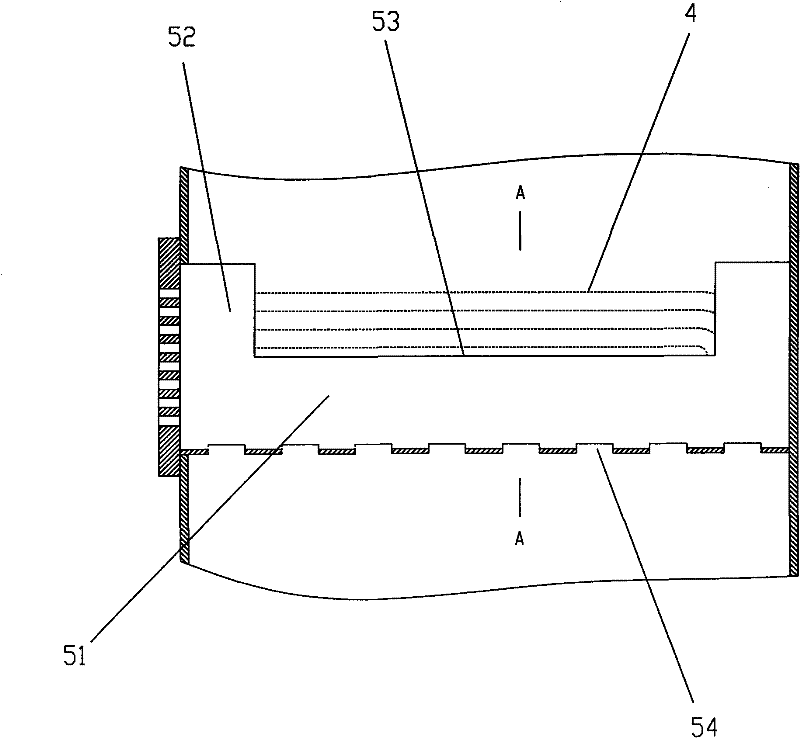

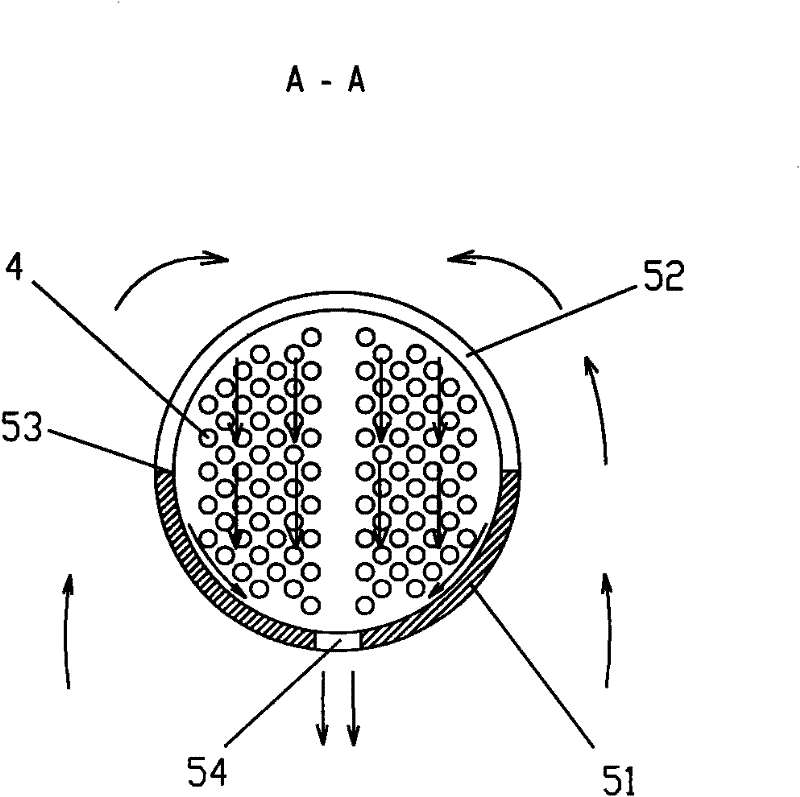

[0015] Such as figure 1 As shown, the present invention discloses an evaporation chamber of a vacuum hot water boiler, including a furnace chamber 1, the upper half of the furnace chamber 1 is a heat exchange chamber 11, and the lower half of the furnace chamber is an evaporation chamber 12, The evaporation chamber 12 is provided with a furnace 2 and a smoke pipe 3, and the evaporation chamber 12 is filled with heat medium water 6, and the heat medium water 6 submerges the furnace 2 and the smoke pipe 3; the heat exchange chamber 11 is provided with There is a heat exchange tube 4, and the furnace 2 communicates with the smoke tube 3. When the high-temperature gas generated when the fuel or gas is burned in the furnace 2 flows through the smoke tube 3, the outer wall of the furnace 2 and the smoke tube 3 and the heat medium water 6 Carry out heat exchange and heat the heat medium water 6 to boil and vaporize in the evaporation chamber 12 to generate negative pressure water vap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com