Method and device based on coal gasification for preparing hydrogen and separating CO2

A CO2, coal gasification technology, applied in the field of coal gasification, can solve the problems of disappearance, large quantity, negative impact on the ecological environment, etc., and achieve the effects of long residence time, high flow rate, and sufficient chemical reaction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

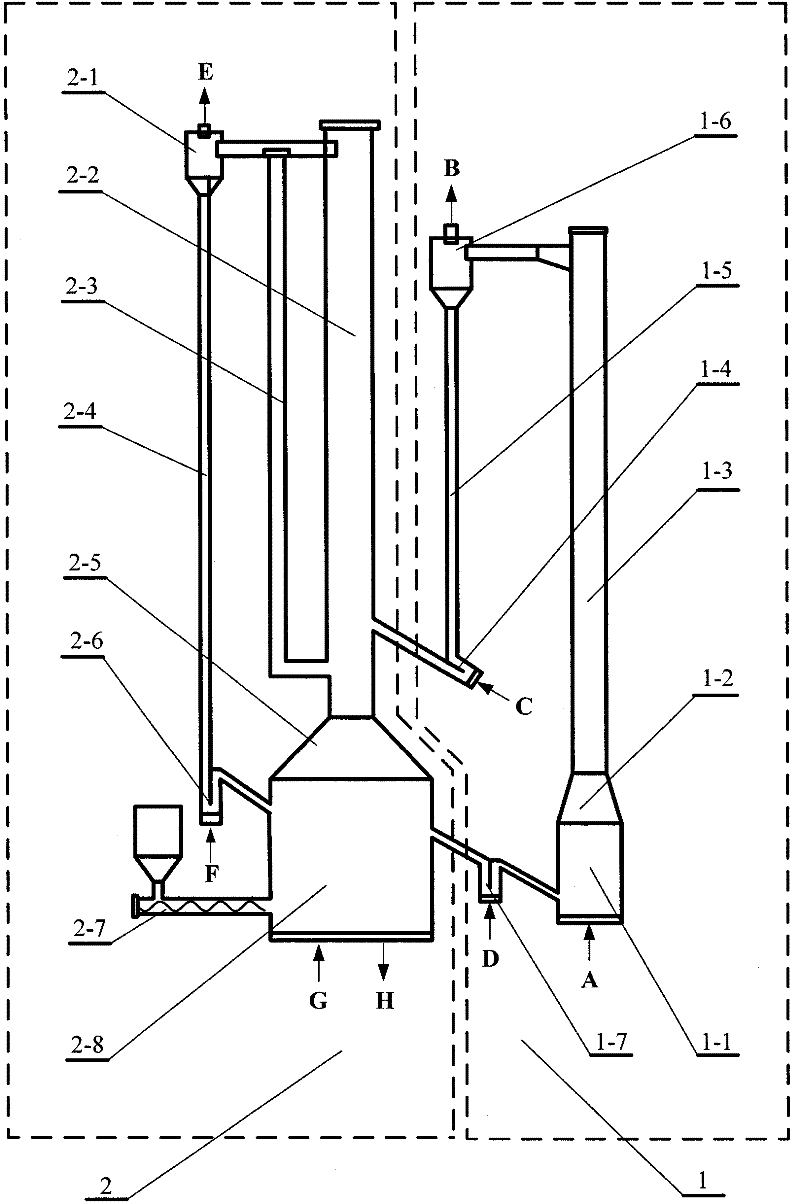

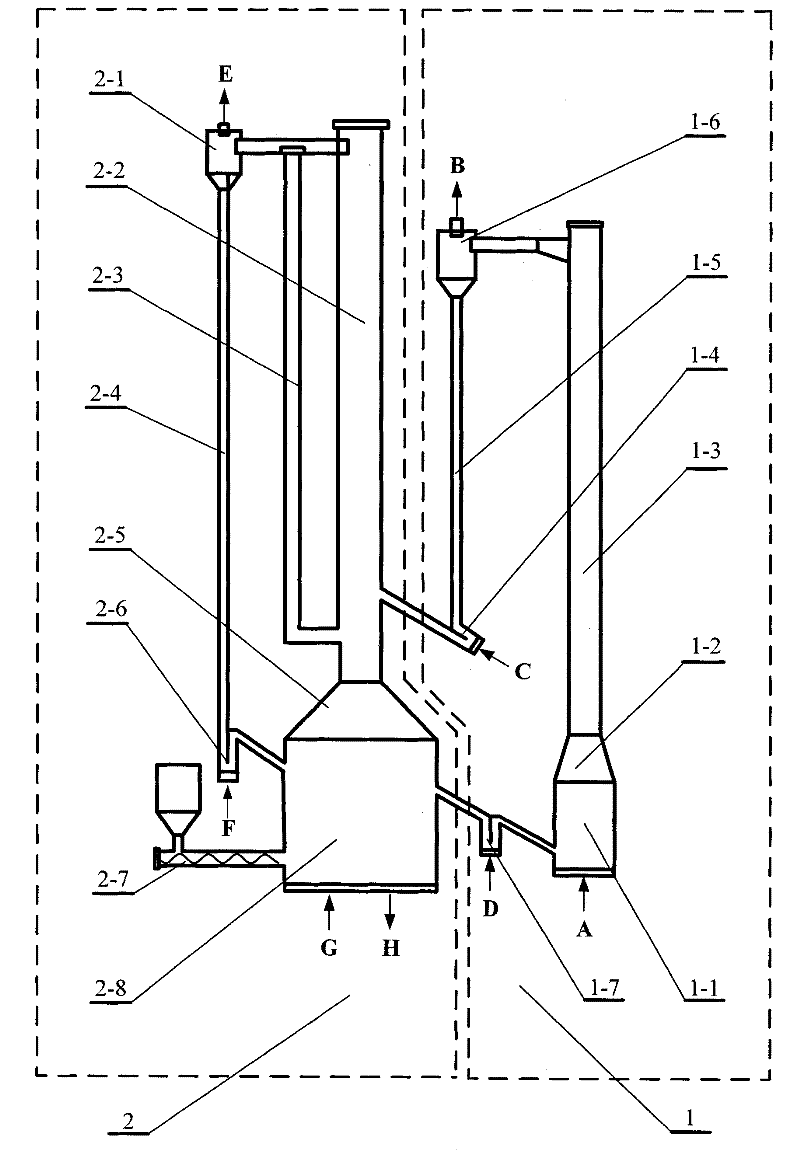

[0015] A method based on coal gasification to produce hydrogen and separate CO 2 method, the coal powder is fed into the mixed gasification reaction chamber 2-8 through the feeder 2-7, water vapor is passed into the lower end G of the mixed gasification reaction chamber, and the temperature of the mixed gasification reaction chamber 2-8 is controlled at 650 ℃ or so. Coal is pyrolyzed to form coke, which reacts with water vapor to generate H 2 , CO and CO 2 , where CO 2 Absorbed by CaO to generate CaCO 3 , due to CO 2 Can be absorbed and solidified by CaO, transformation reaction The equilibrium shifts to the right, and CO is continuously converted to CO by this reaction 2 , CO 2 Then it is absorbed and solidified by CaO; the gas leaving the mixed gasification reaction chamber 2-8 is H 2 and residual CO 2 , which enters the gasification bed riser 2-2 through the transition section 2-5 of the gasification reaction chamber. CaCO generated in mixed gasification reaction ...

Embodiment 2

[0017] A method for realizing the production of hydrogen and separation of CO based on coal gasification described in claim 1 2 The device is composed of gasification reaction fluidized bed 2 and calcium oxide regeneration reaction fluidized bed 1. Gasification reaction fluidized bed 2 is composed of mixed gasification reaction chamber 2-8, gasification reaction chamber transition section 2-5, gasification bed riser 2-2, hydrogen recirculation pipe 2-3, hydrogen separator 2-1 , feeding pipe 2-4, return chute 2-6 and feeder 2-7. The lower end of the gasification bed riser 2-2 is connected to the mixed gasification reaction chamber 2-8 through the mixed gasification reaction chamber transition section 2-5, and the upper end of the gasification bed riser 2-2 is connected to the hydrogen separator 2-1. The upper end is connected to the upper end of the hydrogen recirculation pipe 2-3, the lower end of the hydrogen recirculation pipe 2-3 is connected to the lower end of the gasifi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com