Color ring-decorating wheel hub and manufacture method thereof

A technology of wheel hub and color ring, which is applied in the direction of wheel hub, transportation and packaging, and device for coating liquid on the surface, etc. It can solve the problems of wheel hub that cannot make colorful decorative rings, and achieve the effect of bright color, firm adsorption and uniform thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

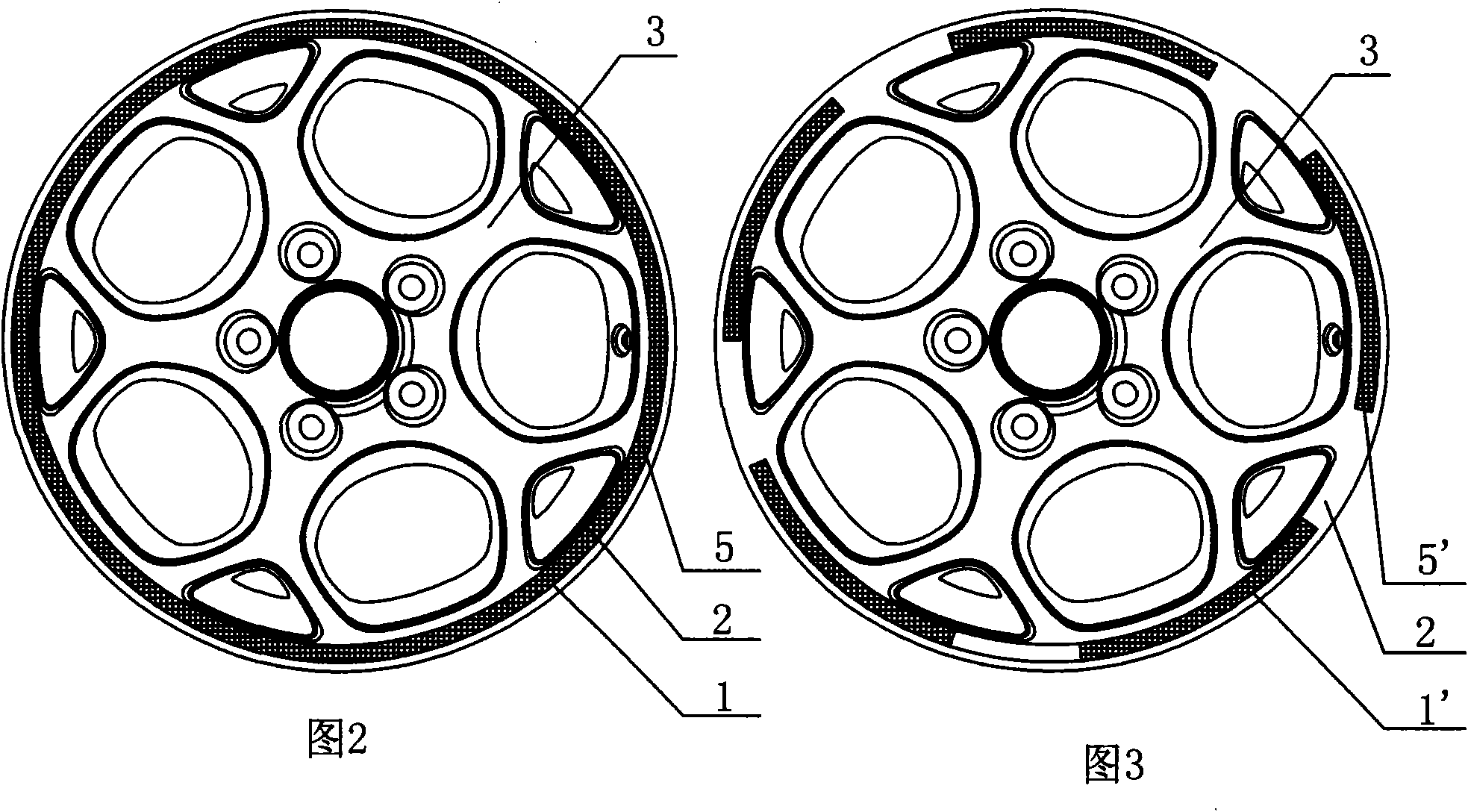

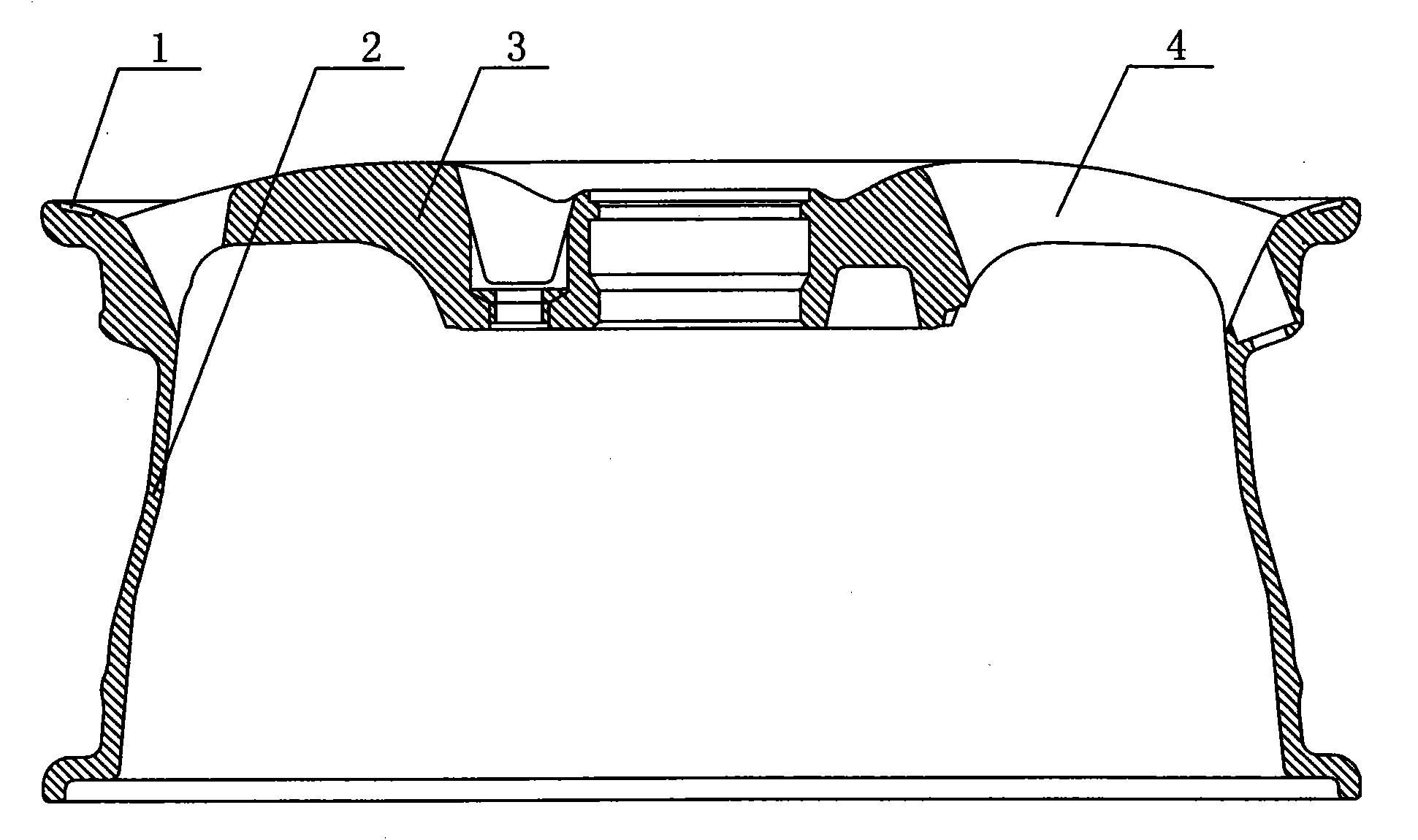

[0058] Example: such as Figure 1 ~ Figure 3 , the black wheel hub 4 processed by the above method is processed, and then the outer edge of the rim 2 is turned to expose the continuous ring groove 1 or the intermittent ring groove 1' of the aluminum alloy, and the ring groove 1 or the ring groove Spray red transparent paint or green, blue, yellow, etc. required colored transparent paint in groove 1' and the entire black wheel hub, and then bake to make the coating solidify and adhere to the ring groove. Put the red circle, green circle, The wheel hubs decorated with blue circles, yellow circles, etc. are installed on the car tires, and the car will see a circle of bright silvery red color circles 5 or red color circles 5′ or green, blue, and yellow color circles, making the vehicle with different personalities.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com