Chelate resin immobilized with dendrimer and preparation method thereof

A dendrimer, chelating resin technology, applied in chemical instruments and methods, other chemical processes, water/sludge/sewage treatment, etc., can solve problems such as unfavorable reuse, difficult product purification, excessive raw materials, etc. Selectivity and adsorption capacity, simplify separation and purification process, improve adsorption performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

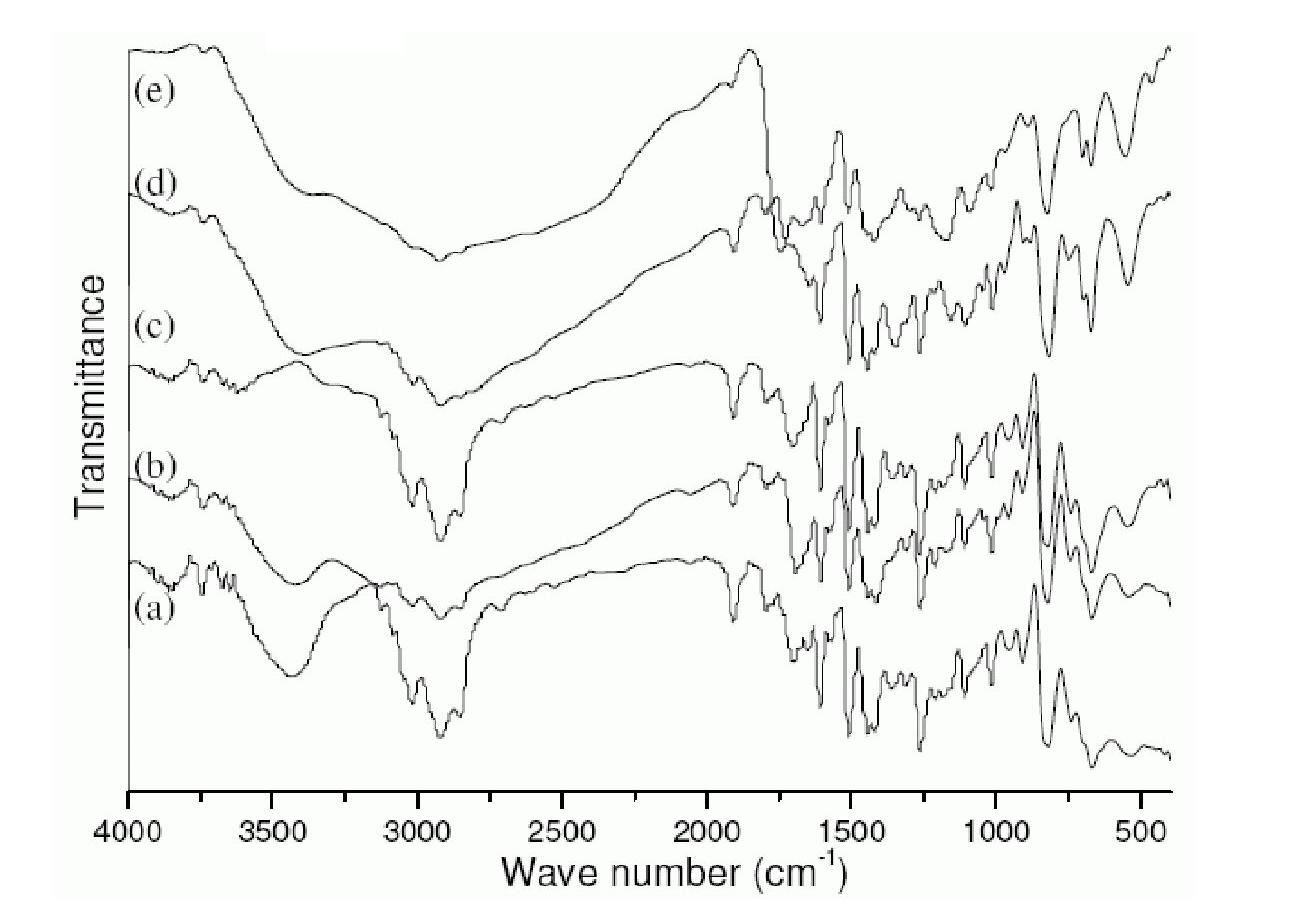

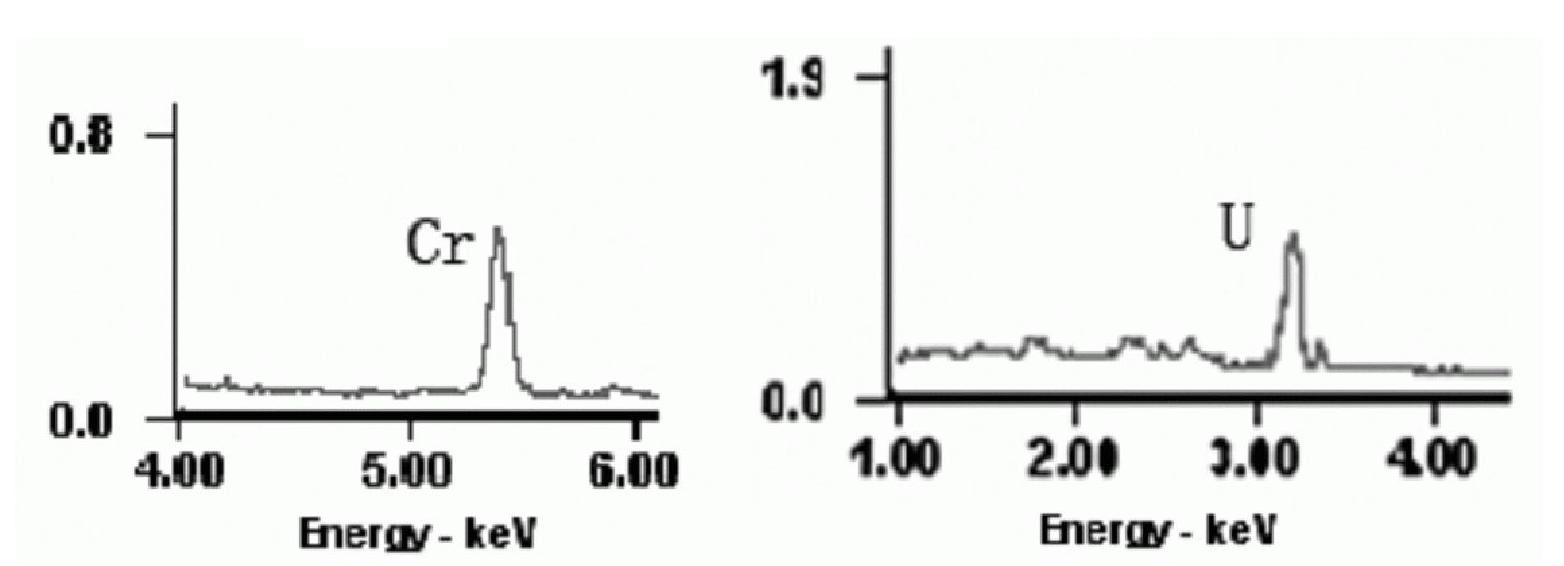

[0030] Chelating resin preparation steps of dendrimers containing amide groups (-COOH or -COONa group modification).

[0031] (1) Select 40-60 mesh commercial chlorine balls, wash with deionized water, 5% hydrochloric acid, deionized water, and 5% sodium hydroxide for more than 3 times, then wash with deionized water until neutral, and extract with ethanol Remove the impurities in it more than 5 times, and then swell for 12-60h.

[0032] (2) Add 50g of pretreated chlorine balls into a three-necked flask, use methanol as a solvent, and add 15- Add 70% hexamethylenetetramine dropwise within 60 minutes, use 20-55% sodium hydroxide solution to adjust pH > 9.5, react at temperature > 15°C for more than 5 hours, remove the mother liquor, and use concentrated hydrochloric acid The resin was treated with alcohol solution, then washed with water and extracted with ethanol for more than 1 hour.

[0033] (3) Put 20g of the product obtained in "step (2)" into a three-necked flask, add 2...

Embodiment 2

[0037] The preparation step of the chelating resin containing amide group dendrimers (containing P group modification).

[0038] (1), (2) are the same as Example 1, step (3) obtains G3.0 product.

[0039] (4) Add the product obtained in "step (3)" into a three-necked flask, add alcohol 150ml, according to the amino group content on the product: vinyl phosphonate = 1: (1.5-3.0) material ratio, at 5 Add vinyl phosphonate under stirring conditions at -100°C, react for 5-40 hours, then filter and wash to obtain chelating resin.

Embodiment 3

[0041] Preparation of Chelating Resin Containing Imino Dendrimers (Alkyl Arsine Modification).

[0042] (1), (2) are the same as Example 1.

[0043] (3) Put 20g of the product obtained in "step (2)" into a three-necked flask, add 20-100ml of alcohol, add 2-30g of acetonitrile dropwise at 3-55°C under stirring conditions, and react for 6-30h to get The half-generation product G0.5; the half-generation resin is hydrogenated under the catalysis of Raney Co (or reduced by tetrahydrolithium aluminum) to obtain the G1.0 product whose terminal group is an amine group. Repeat the preceding steps until the G4.0 product is obtained.

[0044] (4) The product obtained in "step (3)" is added in a three-necked flask, and haloalkyl arsine is added by 0.9-1.8 times of the amount of the amine-based substance, then filtered and washed to obtain a chelating resin.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com