One-step method for synthesizing styrene/ N-benzyl maleimide/ maleic anhydride terpolymer

A technology of maleic anhydride terpolymer and maleimide is applied in the field of polymer heat-resistant and shock-resistant modifiers, which can solve the problems of complex process, unstable quality, complex equipment, etc., and achieve simplified process and reaction time. Short, small equipment investment effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Add 15g N-PMI, 34g St, 1g MAH and 136mL xylene solvent into a 500mL reaction kettle, blow in nitrogen, blow out the residual air in the reaction kettle, raise the temperature to about 76°C, stir for 40-60min to form a homogeneous solution, Then rapidly raise the temperature to about 95°C, put in 0.25g of dibutyl peroxide o-(tere)phthalate, raise the temperature to about 125°C while reacting, and keep the pressure constant for 4 hours. After the reaction, the temperature was raised to boiling to evaporate the residual solvent and monomer, and then filtered and dried to obtain a light yellow powder product.

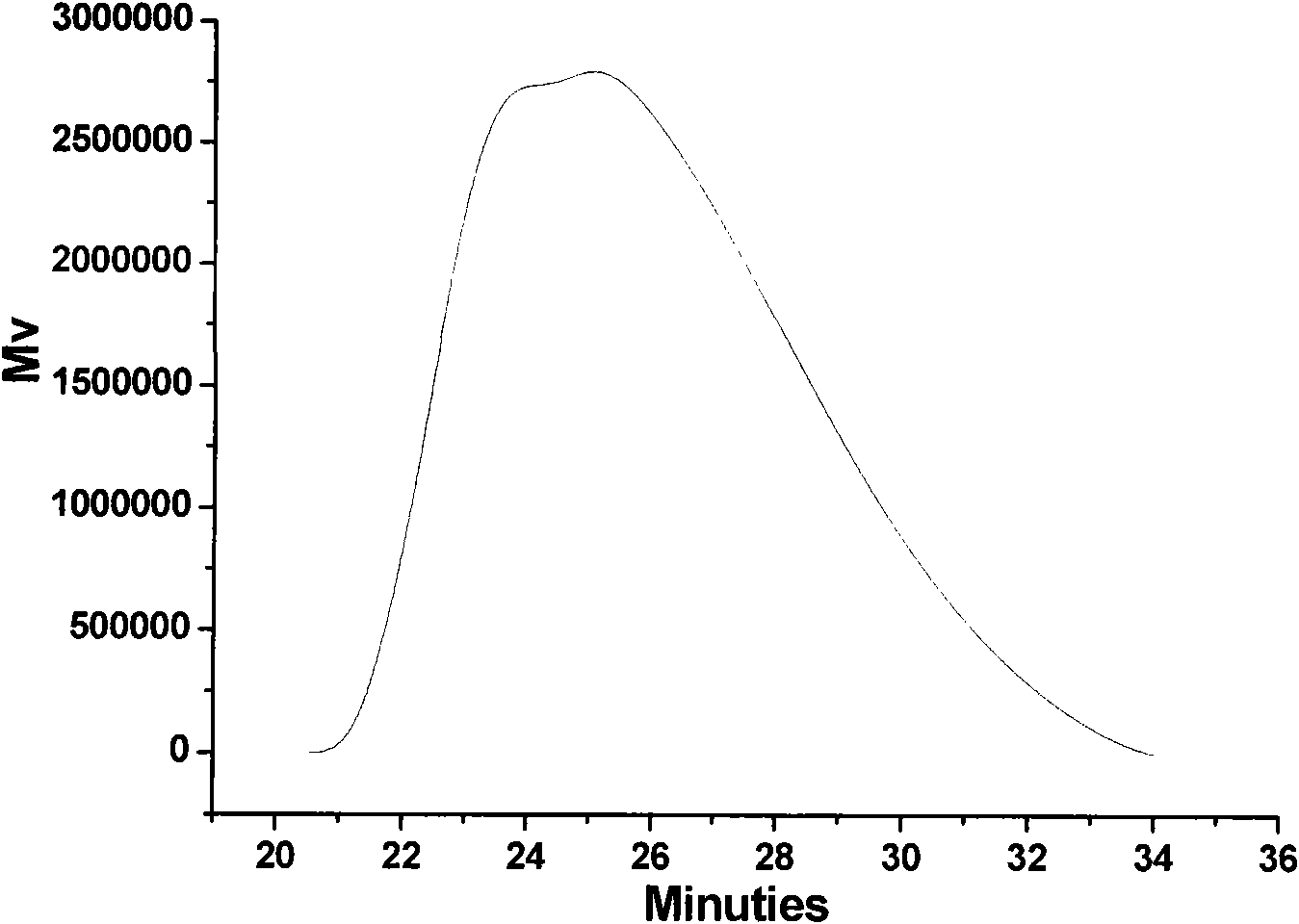

[0019] from figure 1 The following conclusions can be drawn from the comparison of polystyrene and styrene / N-PMI / MAH spectral lines in the infrared spectrum of styrene / N-PMI / MAH ternary copolymerization: 1777cm -1 and 1712cm -1 The carboxyl characteristic absorption peaks of maleic anhydride and N-phenylmaleimide respectively, 1454cm -1 , 1495cm -1 Benzene ring a...

Embodiment 2

[0026] Add 20g N-PMI, 29g St, 1g MAH and 136mL xylene solvent into a 500mL reaction kettle, blow in nitrogen, blow out the residual air in the reaction kettle, raise the temperature to about 76°C, stir for 40-60min to form a homogeneous solution, Then rapidly raise the temperature to about 95°C, put in 0.25g of dibutyl peroxide o-(tere)phthalate, raise the temperature to about 125°C while reacting, and keep the pressure constant for 4 hours. After the reaction, the temperature was raised to boiling to evaporate the residual solvent and monomer, and then filtered and dried to obtain a light yellow powder product.

Embodiment 3

[0028] Add 25g N-PMI, 24g St, 1g MAH and 136mL xylene solvent into a 500mL reaction kettle, blow in nitrogen, blow out the residual air in the reaction kettle, raise the temperature to about 76°C, stir for 40-60min to form a homogeneous solution, Then rapidly raise the temperature to about 95°C, put in 0.25g of dibutyl peroxide o-(tere)phthalate, raise the temperature to about 125°C while reacting, and keep the pressure constant for 4 hours. After the reaction, the temperature was raised to boiling to evaporate the residual solvent and monomer, and then filtered and dried to obtain a light yellow powder product.

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com