Method for preparing aluminum titanate nano powder by non-hydrolytic sol-gel process

A technology of nano-powder and aluminum titanate, which is applied in the direction of nanotechnology, nanotechnology, nanostructure manufacturing, etc., can solve the problems of coarsening, aluminum titanate powder agglomeration, and coarse powder particles, and achieve high synthesis rate, Agglomeration inhibition and good dispersibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

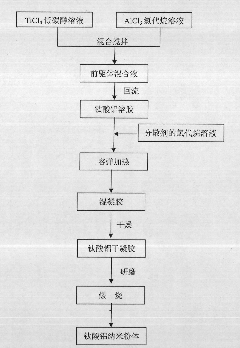

Method used

Image

Examples

Embodiment 1

[0031] Aluminum titanate sol was prepared according to the molar ratio of aluminum to titanium: 2:1, and 9.707g of anhydrous aluminum trichloride (analytical pure) was dissolved in 5.0ml of chloroform (chemically pure), sealed for use; 4.0ml of tetrachloromethane Titanium chloride (chemically pure) was added dropwise into 17.0 ml of n-butanol (chemically pure), and after sufficient magnetic stirring, a n-butanol solution of titanium tetrachloride was obtained. Then slowly add the n-butanol solution of titanium tetrachloride into the chloroform solution of anhydrous aluminum trichloride, and after magnetic stirring is sufficient, put the mixed solution in an oil bath at 80°C for 8 hours to form titanic acid. Aluminum sol. Dissolve 0.06g PEG1000 (analytical pure) in 5.0ml dichloromethane (chemically pure), add the dichloromethane solution of PEG1000 dropwise in aluminum titanate sol, carry out magnetic stirring, put into auxiliary pressure field reaction vessel, A wet gel was o...

Embodiment 2

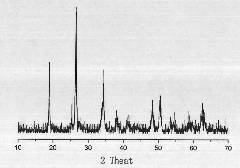

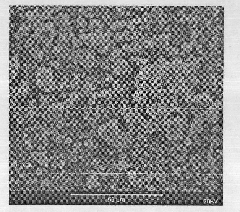

[0033] In Example 1, 17.0ml of n-butanol (chemically pure) was changed to 11.0ml of ethanol (chemically pure), PEG1000 was changed to glycerin, and the precursor mixed solution was refluxed for 10 hours under 90°C oil bath heating condition to form aluminum titanate sol, and other The conditions remain unchanged, and aluminum titanate nanopowder with good dispersibility is obtained. The XRD analysis of product shows that the powder synthesized is aluminum titanate (see Figure 9 ); Figure 10 The TEM photos in the above show that the powder has good dispersion and the average particle size is less than 30nm.

Embodiment 3

[0035] Change PEG1000 in Example 1 to polyvinylpyrrolidone, change chloroform to carbon tetrachloride, change 17.0ml n-butanol (chemically pure) to 14.0ml isopropanol (chemically pure), and put aluminum titanate sol into auxiliary pressure After the field reaction container, the aluminum titanate wet gel was obtained by heating at 130° C. for 20 h, and the aluminum titanate nanopowder with good dispersibility was obtained under the same other conditions. The XRD analysis of product shows that the powder synthesized is aluminum titanate (see Figure 11 ); Figure 12 The TEM photos in the above show that the powder has good dispersion and the average particle size is less than 30nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com