Machine head and machine tail centralized lubricating system of belt conveyor

A belt conveyor, centralized lubrication technology, applied in the direction of conveyor objects, transportation and packaging, cleaning devices, etc., can solve the problems of low lubrication efficiency, uneven lubrication, discontinuous lubrication, etc., to improve lubrication efficiency and oil circuit layout And the effect of easy installation and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

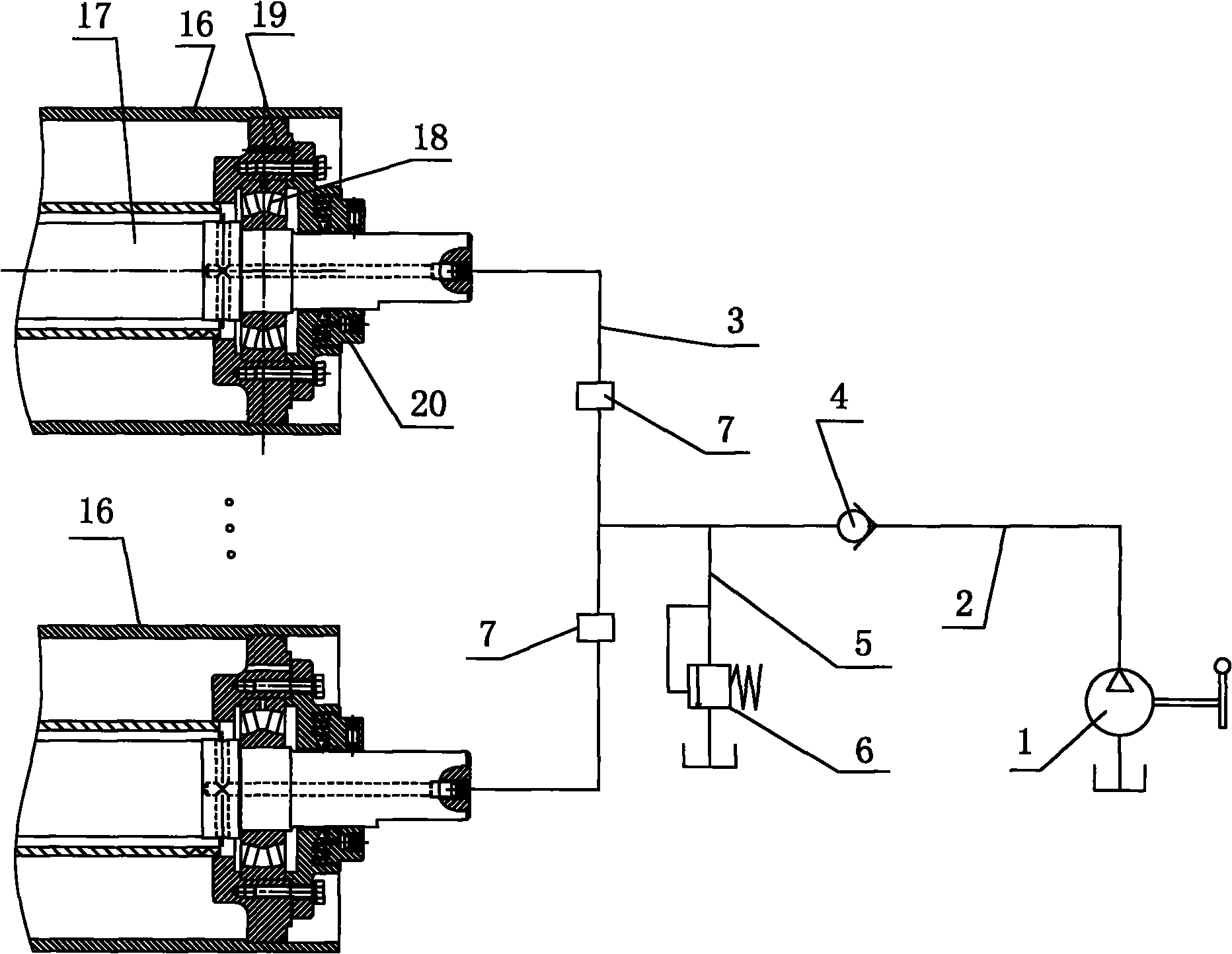

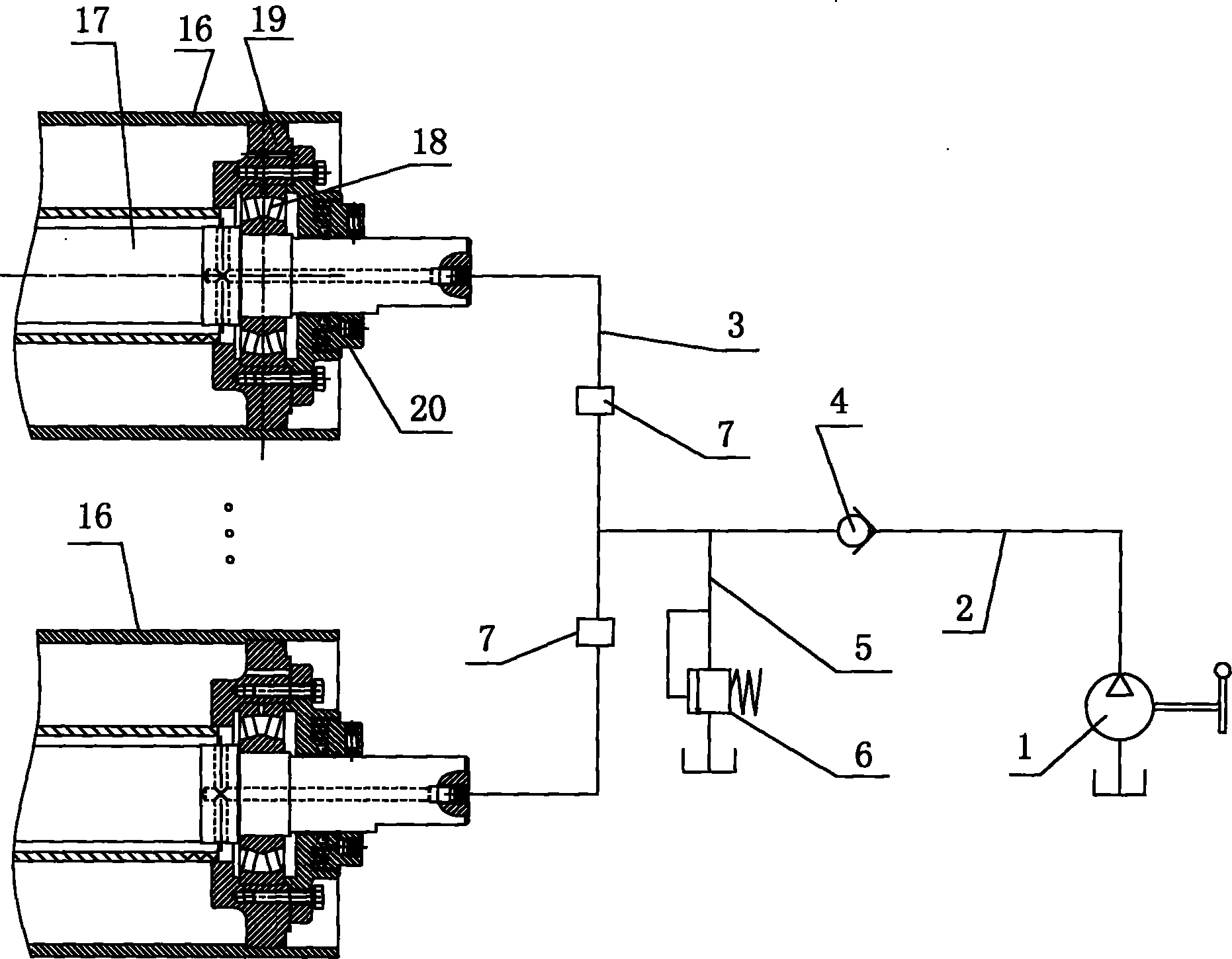

[0031] Such as figure 1 As shown, the present invention includes a main oil supply pipeline 2, a lubricating pump that continuously injects the lubricating grease in the oil storage tank into the main oil supply pipeline 2, a check valve 4 installed on the main oil supply pipeline 2, and respectively connected with the main oil supply pipeline. A plurality of oil supply branches 3 connected to the oil outlets of 2, a plurality of oil supply distributors 7 respectively installed on the plurality of oil supply branches 3, an oil return pipeline 5 communicated with the main oil supply pipeline 2 and installation The overflow valve 6 on the oil return line 5, the oil inlet of the main oil supply line 2 is connected to the oil filling port of the lubricating pump, and the oil outlets of a plurality of oil supply branches 3 are connected to the head of the belt conveyor. The lubricating parts required to be lubricated at the rear of the machine are connected, and the oil outlet of t...

Embodiment 2

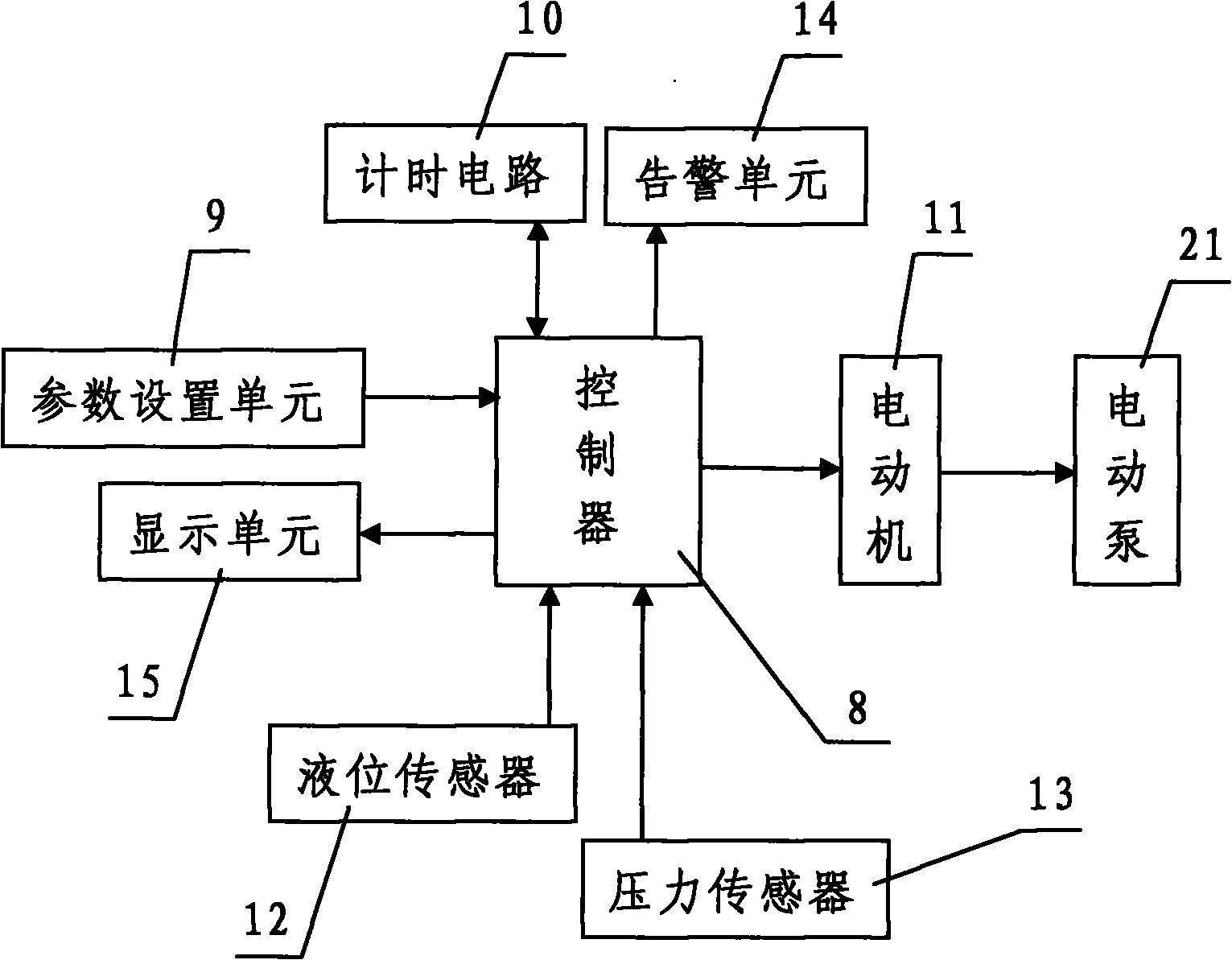

[0035] Such as figure 2 As shown, in this embodiment, the difference from Embodiment 1 is that the lubricating pump is an electric pump 21 driven by a motor 11, and also includes a controller 8 and a parameter setting unit 9 respectively connected to the controller 8 and timing circuit 10 , the controller 8 is connected to the motor 11 and the motor 11 is connected to the electric pump 21 . in addition. The present invention also includes a liquid level sensor 12 for real-time detection of the oil level in the oil storage tank, a pressure sensor 13 for real-time detection of the oil supply pressure inside the main oil supply pipeline 2, and a sensor connected to the controller 8. The alarm unit 14 , the liquid level sensor 12 and the pressure sensor 13 are both connected to the controller 8 , and also includes a display unit 15 connected to the controller 8 . In this embodiment, the structures, connections and working principles of other parts are the same as those in Embod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com