Gas bag polishing tool capable of initiatively distributing abrasive particles

An airbag polishing and active distribution technology, which is applied in the direction of grinding/polishing equipment, manufacturing tools, surface polishing machine tools, etc., can solve the problems of reducing the effective participation rate of abrasive grains, long polishing cloth time, and reducing polishing efficiency, etc. The effect of effective participation rate, improvement of polishing surface quality, and improvement of polishing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

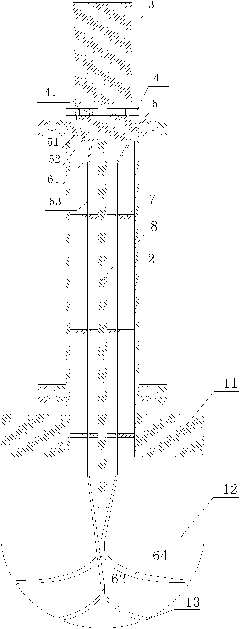

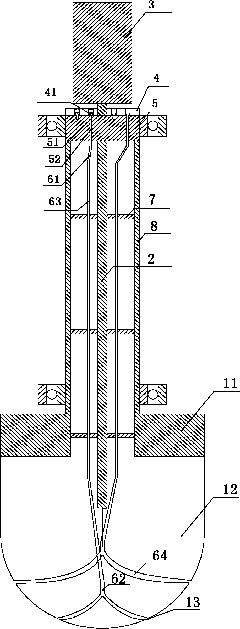

[0020] With reference to accompanying drawing, further illustrate the present invention:

[0021] The airbag polishing tool that can actively distribute abrasive grains includes an airbag, a gas transmission shaft 2 and an air pump. The airbag includes a cage 11 and an airbag cover 12, and the airbag cover 12 is sealed and installed on one end of the cage 11 , the cage 11 is a hollow structure; the gas transmission shaft 2 is a semi-hollow shaft, the hollow section of the gas transmission shaft 2 is connected with the other end of the cage 11, and the gas transmission The solid end of the shaft 2 is connected with a rotary drive mechanism 3; the gas transmission shaft 2 is set in a gas conduction sleeve, and the gas conduction sleeve is provided with a through hole, and the through hole is connected with the The air outlet of the air pump is connected, and the air guide sleeve is sealed with the air transmission shaft 2;

[0022] The polishing tool also includes a liquid inje...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com