Integration method of steel tube inner wall and outer wall powder spraying, curing and film-forming and device thereof

A technology of inner and outer walls and steel pipes, which is applied in the field of epoxy resin powder spraying method and its device, can solve the problems of high probability of damage during handling of the cured film, inability to make epoxy resin anti-corrosion film, and great influence on the quality of the cured film. Simplified pre-treatment process, light weight, high powder concentration effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

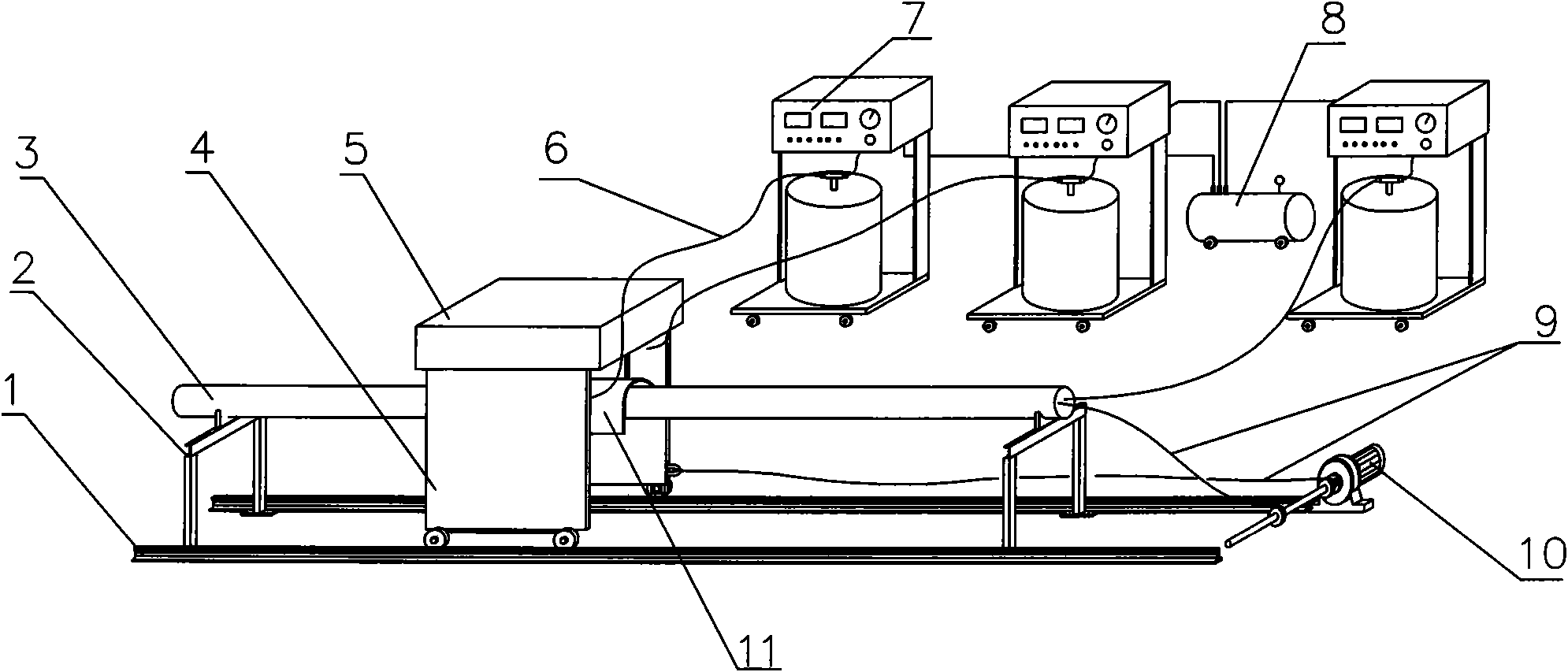

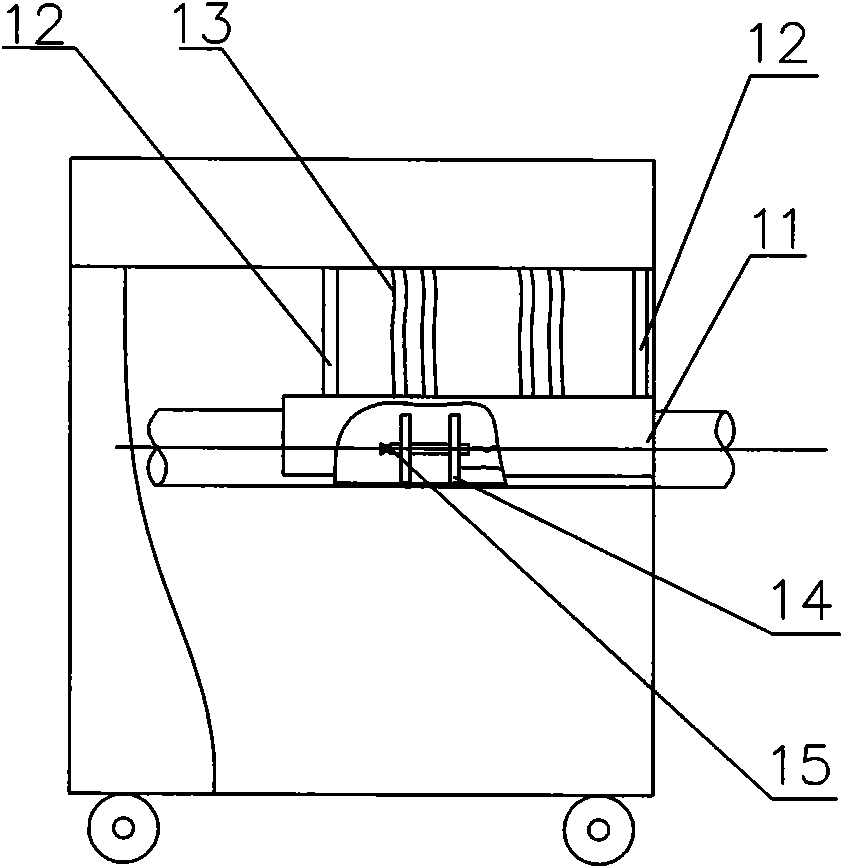

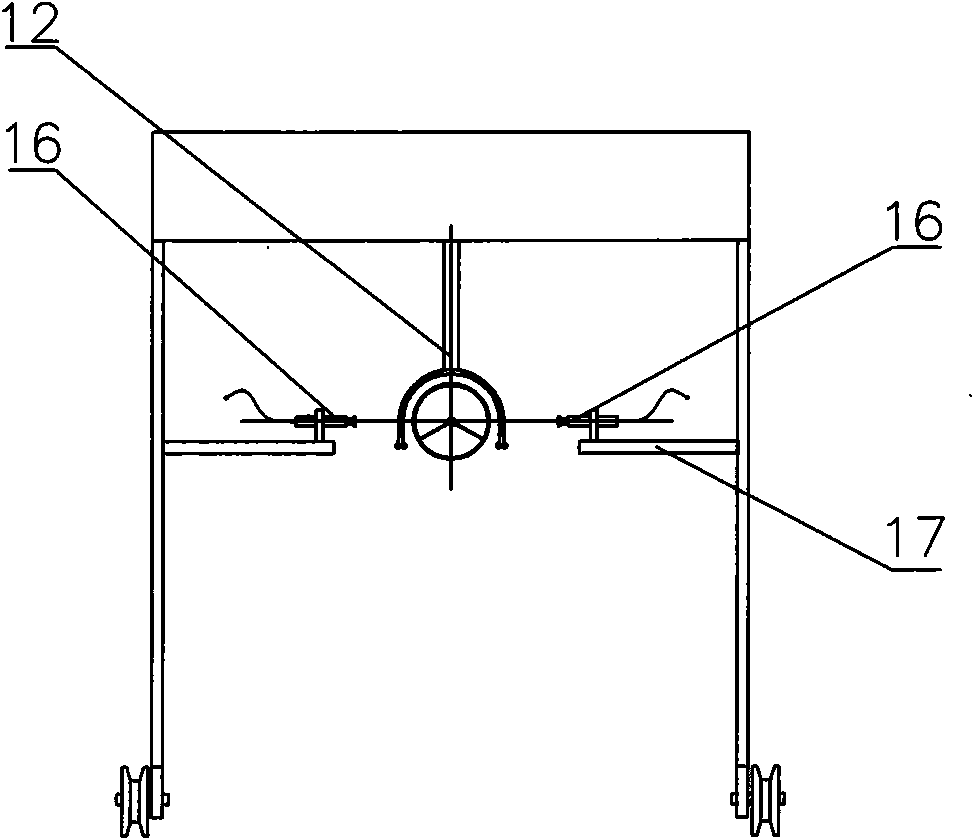

[0034] The integrated device for powder coating, solidification and film formation on the inner and outer walls of the steel pipe includes a track 1, a bracket 2 for placing the steel pipe 3 to be sprayed, a rail car 4, electrostatic spraying equipment 7 and an air pump 8. The steel pipe support 2 is two rectangular parallelepiped frames welded by 60mm angle steel, and two sections of 5mm long angle steel are welded side by side on the frame in the center of the top to place the steel pipe and play the role of fixing the steel pipe and preventing the steel pipe from moving . When in use, refer to the running track of the integrated rail car and the length of the steel pipe to be sprayed, and place the positions of the two steel pipe supports 2 so that the steel pipe 3 to be sprayed is in the center of the track; the steel pipe to be sprayed is 100-800 mm in diameter, Seamless steel pipes, straight seam welded pipes and spiral welded pipes with wall thickness less than 12mm; he...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com