Disinfection machine for bottle cap

A technology for sterilizers and bottle caps, which is applied in chemistry and other fields, can solve problems such as increased production costs, increased equipment complexity, and short-circuited bottle caps, and achieves the effects of reducing the length and size of the equipment, facilitating observation and maintenance, and thoroughly sterilizing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

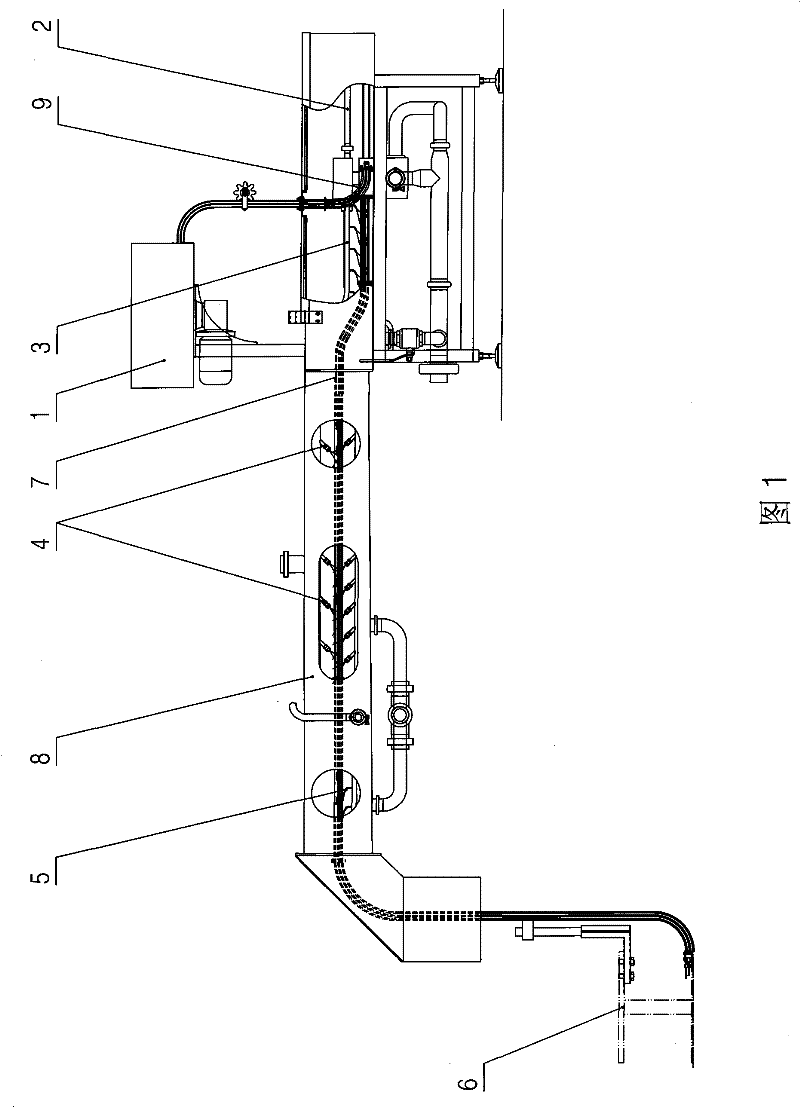

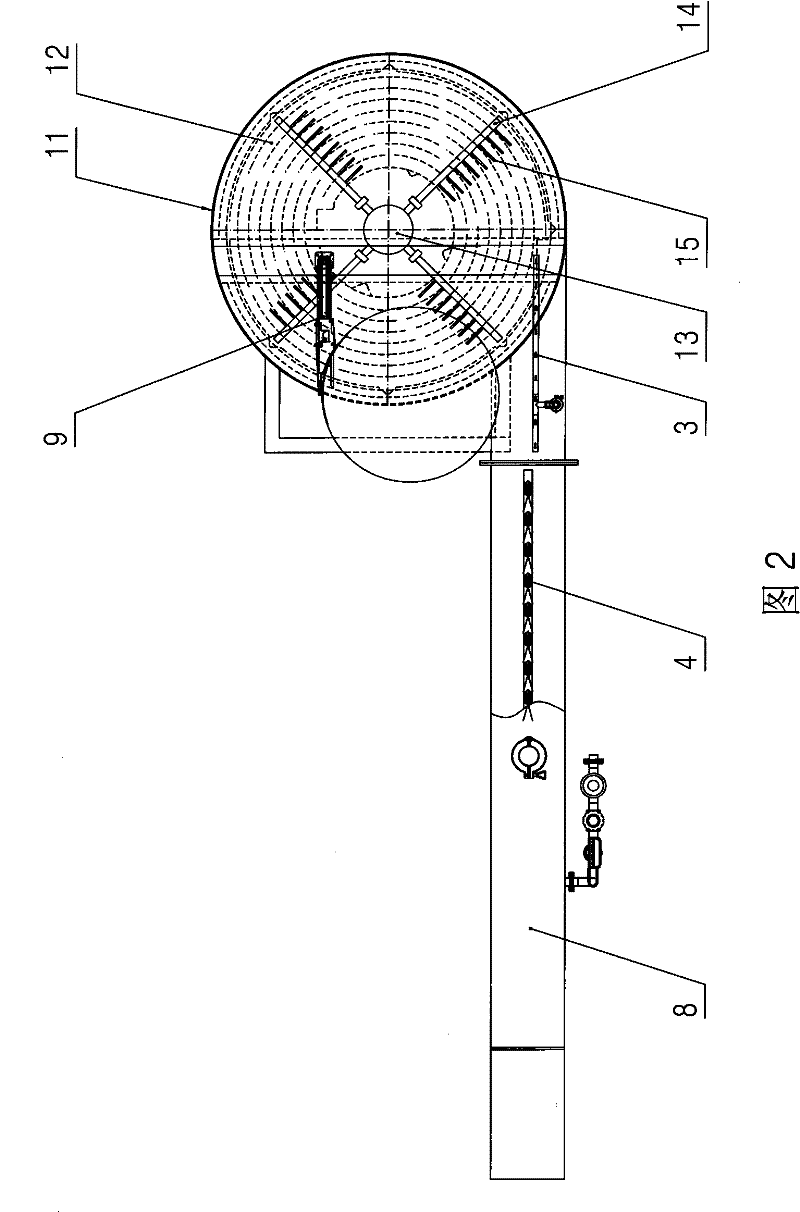

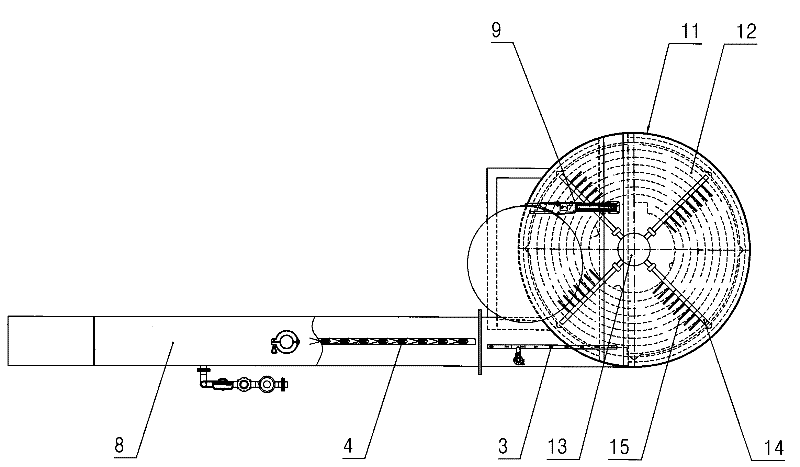

[0015] Such as figure 1 As shown, the bottle cap sterilizer of the present invention includes: a closed conveying channel 8 and a sterilizing device 2 connected thereto, the conveying channel 8 is sequentially provided with an aseptic air blowing turning device 3 and a sterile water spraying device 4 and aseptic gas drying device 5, also be provided with the bottle cap conveying device 7 that runs through conveying channel 8, as figure 2 As shown, the disinfection device 2 includes: a disc-shaped immersion tank 11, the center of the immersion tank 11 is provided with a tube base 13, and the immersion tank 11 is surrounded by a tube base 13 formed by eight circles of involute rails 12. Disinfection track, the pipe seat 13 is provided with four disinfectant spray assemblies, these four disinfectant spray assemblies are evenly distributed above...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com