A fabric scouring and bleaching device

A fabric, scouring and bleaching technology, applied in the treatment of textile material containers, spraying/jetting textile materials, etc., can solve the problems of short circuit of liquid flow, affecting the uniformity of scouring and bleaching, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

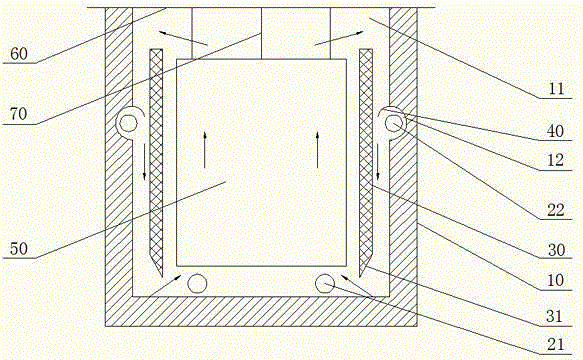

[0016] The present invention will now be further described in detail in conjunction with the accompanying drawings and embodiments. These drawings are all simplified schematic diagrams, only illustrating the basic structure of the present invention in a schematic manner, so it only shows the composition related to the present invention.

[0017] Such as figure 1 As shown, a fabric scouring and bleaching device comprises a cuboid-shaped barrel body 10 with one end being a fabric 50 inlet 11, the fabric 50 can be hoisted by a loop rope 70, the loop rope 70 is hung on the hanging rod 60, and the hanging rod 60 is left to rest. On the inlet 11 of the barrel 10 , the fabric 50 can be hung in the barrel 10 . The inner bottom of barrel body 10 of the present invention is provided with first steam pipe 21, directly heats first steam pipe 21, and steam is ejected upwards, makes practice liquid pour into the center of barrel body 10 first, makes practice liquid mix evenly; A baffle pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com