Process for producing sterilizing agent of medical high concentrition ozone and equipment thereof

A disinfectant, high-concentration technology, applied in ozone preparation, oxidized water/sewage treatment, chemistry, etc., can solve the problems of increasing cycle time, only cooling, and increasing equipment cost, achieving good temperature control effect, convenient operation, Equipment simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

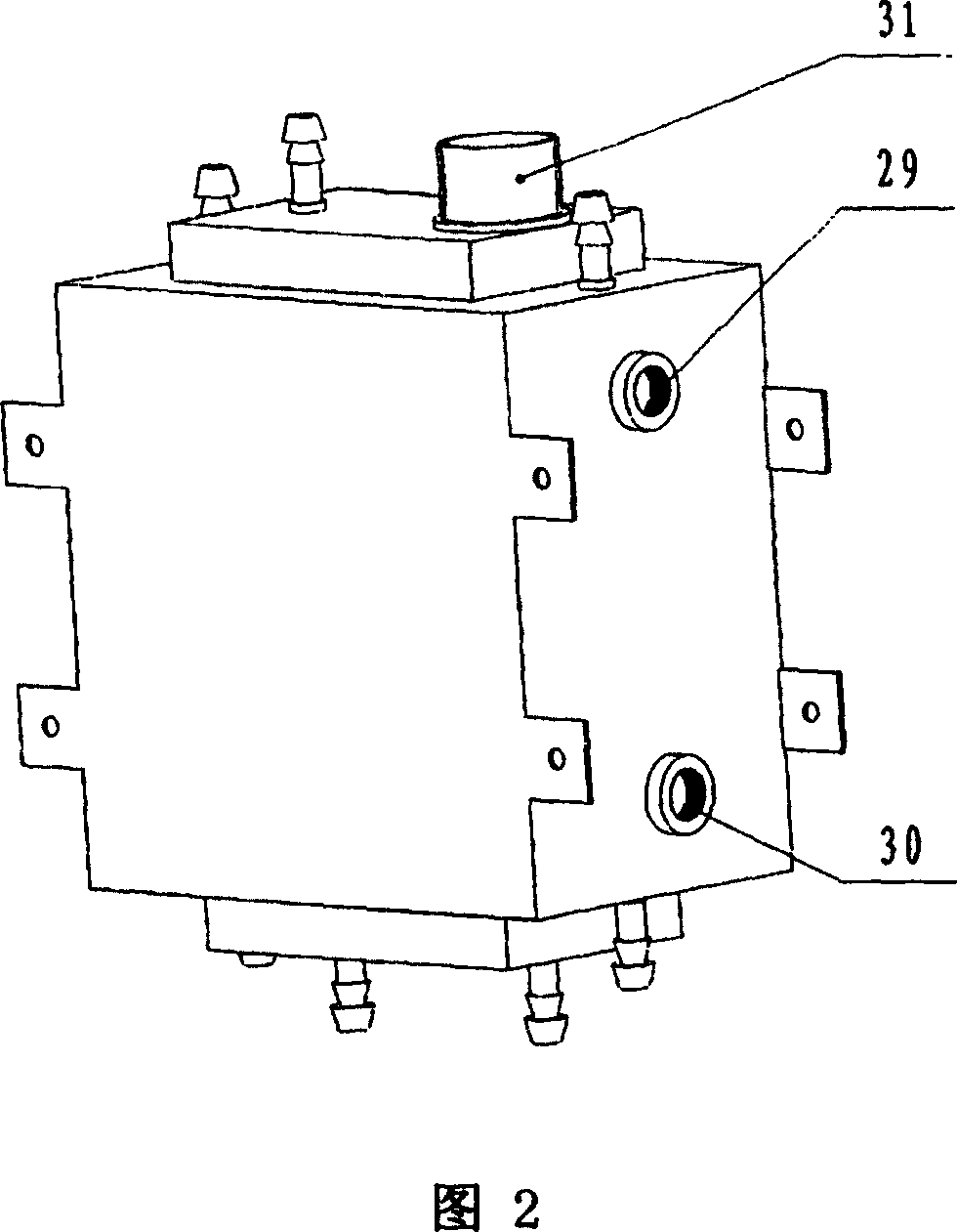

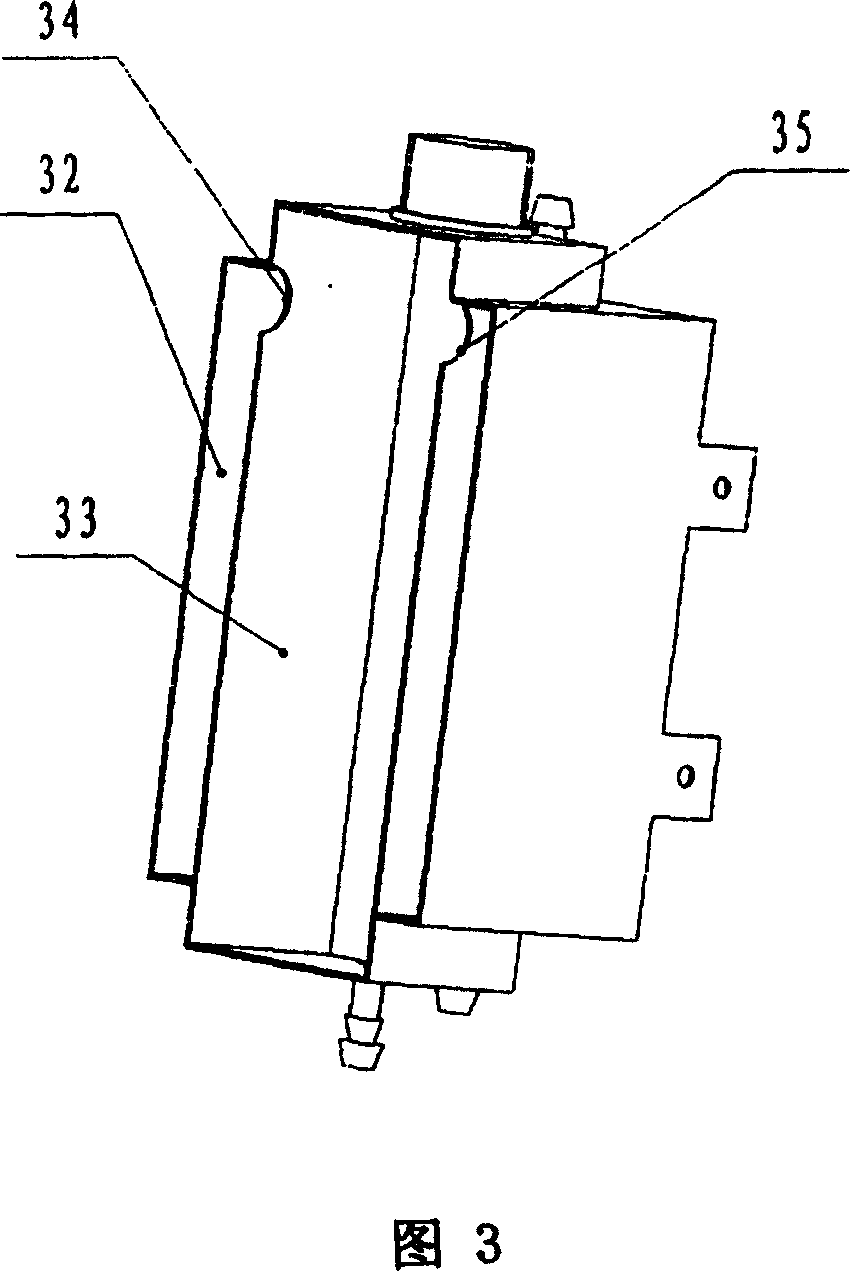

[0043] The following is a detailed description of the accompanying drawings for the embodiment of the process and wound disinfection and cleaning equipment of the present invention, so that those skilled in the art can understand the characteristics and advantages of the present invention more clearly.

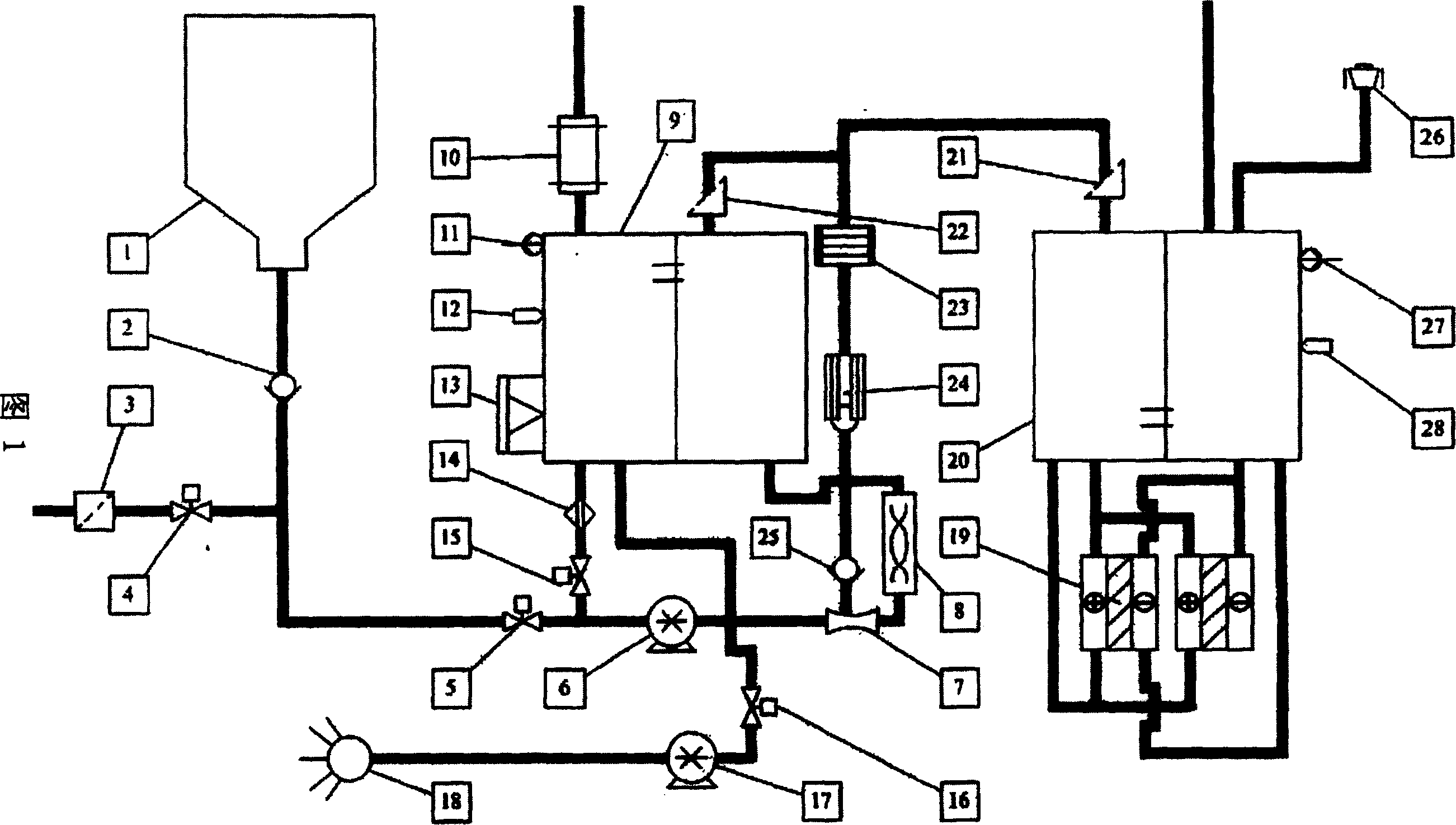

[0044] The detailed workflow of process method of the present invention is as shown in Figure 1:

[0045] A. a plurality of electrolytic type ozone generators (19) connected in parallel are opened to generate ozone gas, and then enter the high-voltage corona type ozone generator (24) after making the gas dry and dehumidified, further improving the output and concentration of ozone;

[0046] b. Open the main water inlet valve (5) first, the disinfectant stock solution is sucked by the circulating pump (6), and the ozone gas is inhaled when passing through the high-pressure jet negative pressure absorption device (7), and then enters the disinfectant through the static mixer (8) ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com