Bidirectional cylinder recoiling mechanism for firework cylinder

A technology of unwinding and fireworks, which is applied in pyrotechnics, cardboard winding products, attacking equipment, etc. It can solve the problems of affecting the processing efficiency of paper cans, unfavorable automation of unwinding cans, and damage of paper cans, so as to realize the cutting of paper cans Automated and assembly line operations, improving the efficiency of paper tube cutting, ensuring the effect of roundness and strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

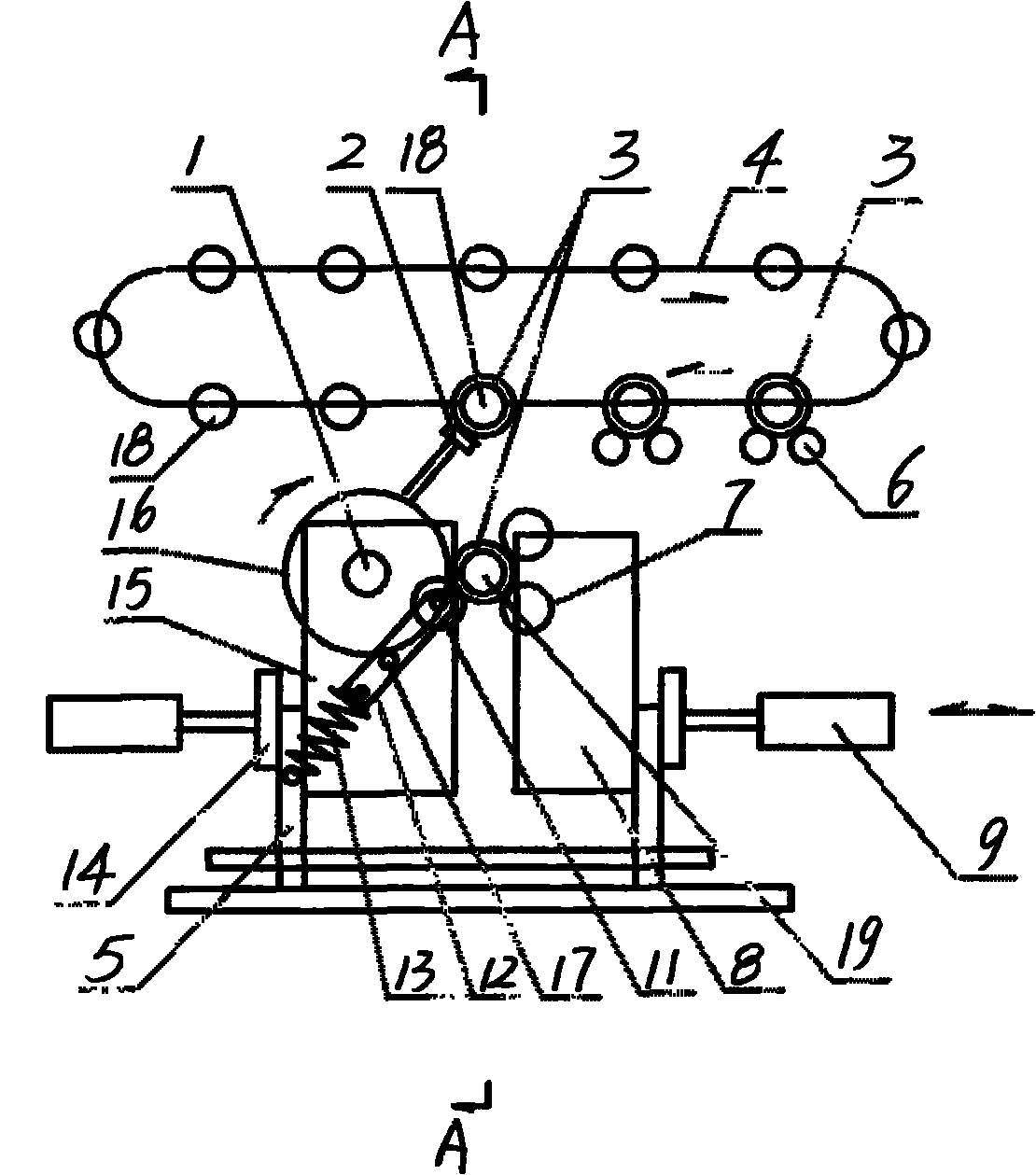

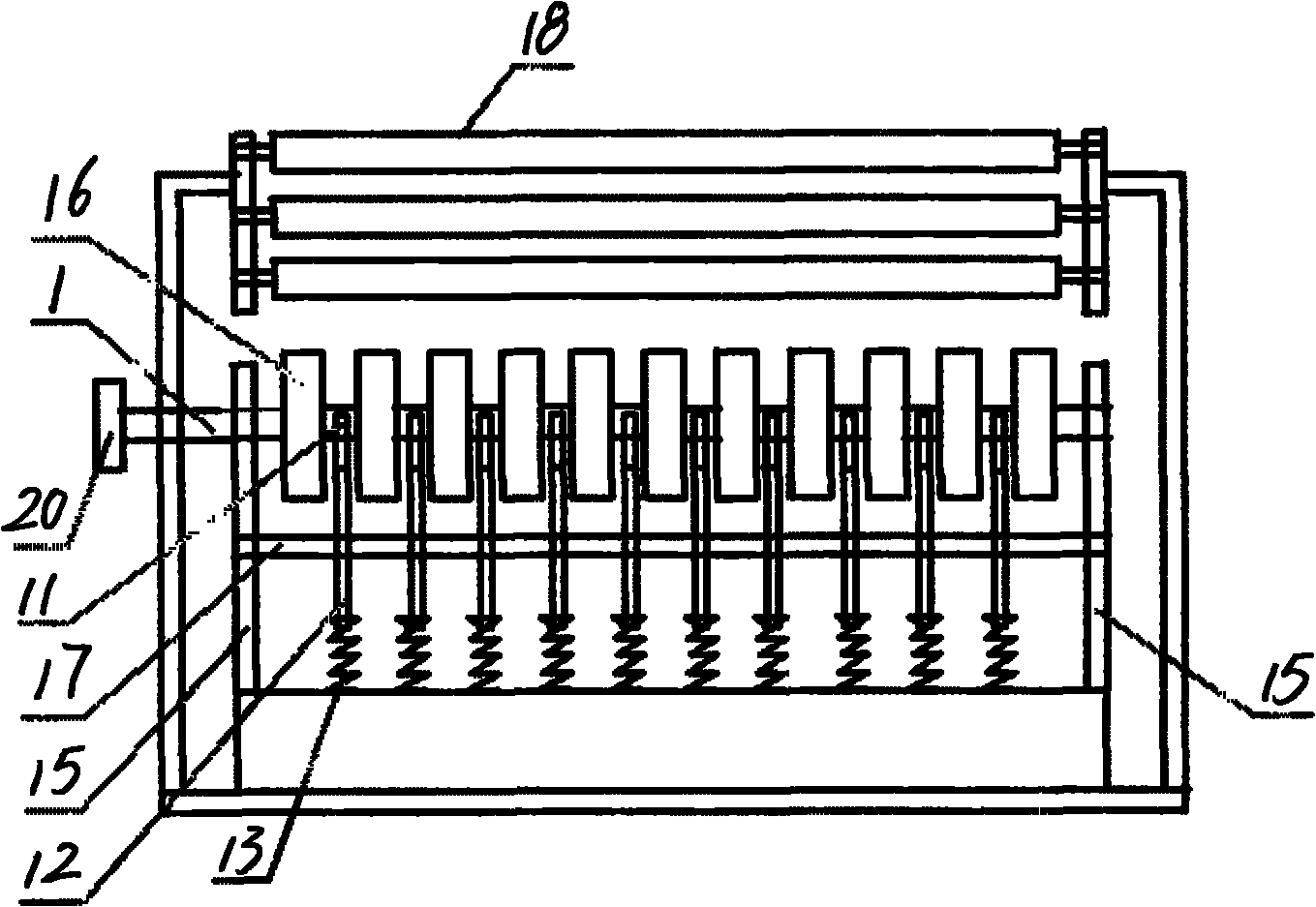

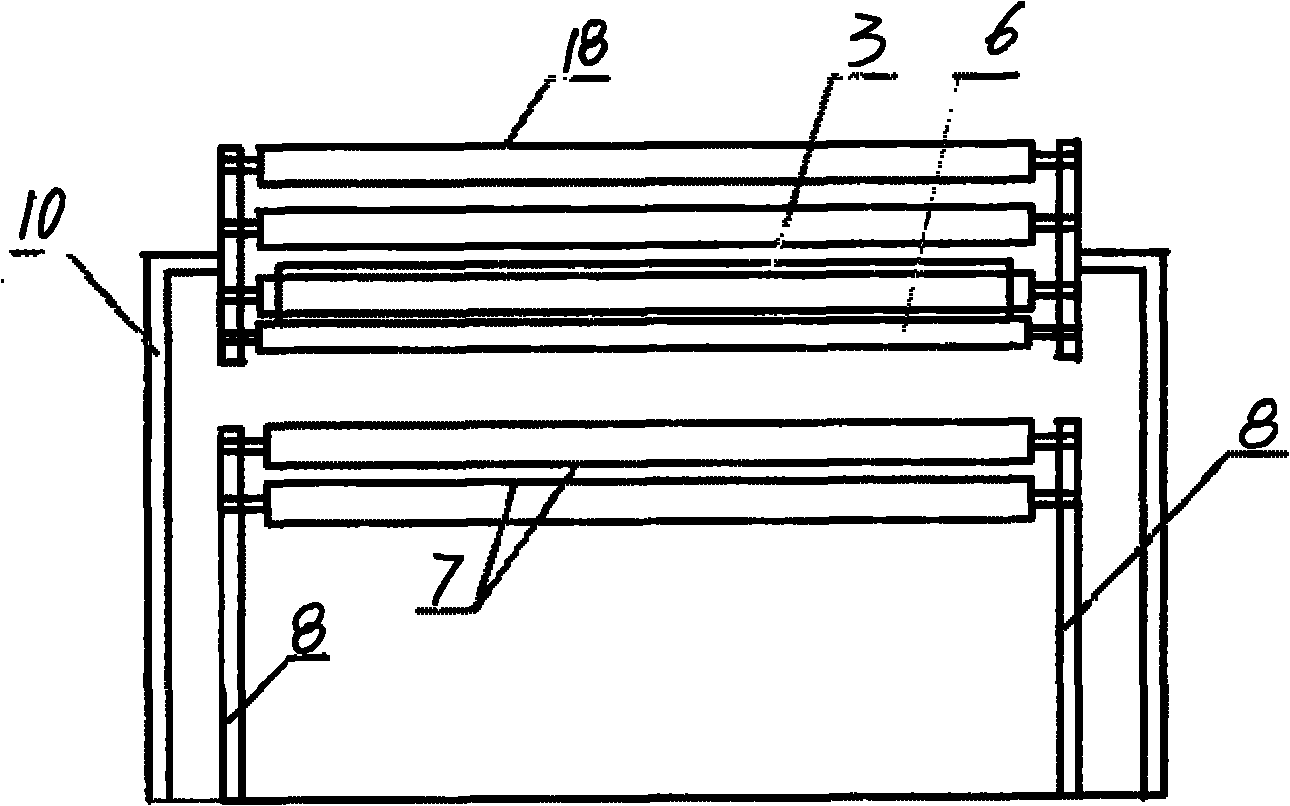

[0012] exist figure 1 , figure 2 , image 3 and Figure 4 Among them, the two-way unwinding mechanism for fireworks tubes is located under the upper clutch mandrel 18 in the tube rolling mechanism, which includes a lower clutch mandrel 19, a main idler 16, a paper cutting idler 7 and a cutter 11, The coiling mechanism is a circular operation mechanism driven by the transmission chain 4. There are 12 upper clutch mandrels 18 arranged at intervals on the transmission chain. The upper clutch mandrels can move in a circle with the transmission chain. Below the two upper clutch mandrels are respectively provided with two roll tube support rollers 6, wherein the two roll tube support rollers at the first position and the upper clutch mandrel form a base paper roll tube forming device, and the two roll tube support rollers at the second position are connected with the upper clutch mandrel. The upper clutch mandrel forms the rolling tube rolling device. When the rolled paper tube ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com