Hydraulic wedge-shaped wire clamp installer

A wedge-shaped wire clip and installer technology, applied in the direction of overhead line/cable equipment, etc., can solve the problems of high use cost, insufficient front impact force, noise pollution, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to better understand the technical solution of the present invention, the following will be described in detail through specific examples:

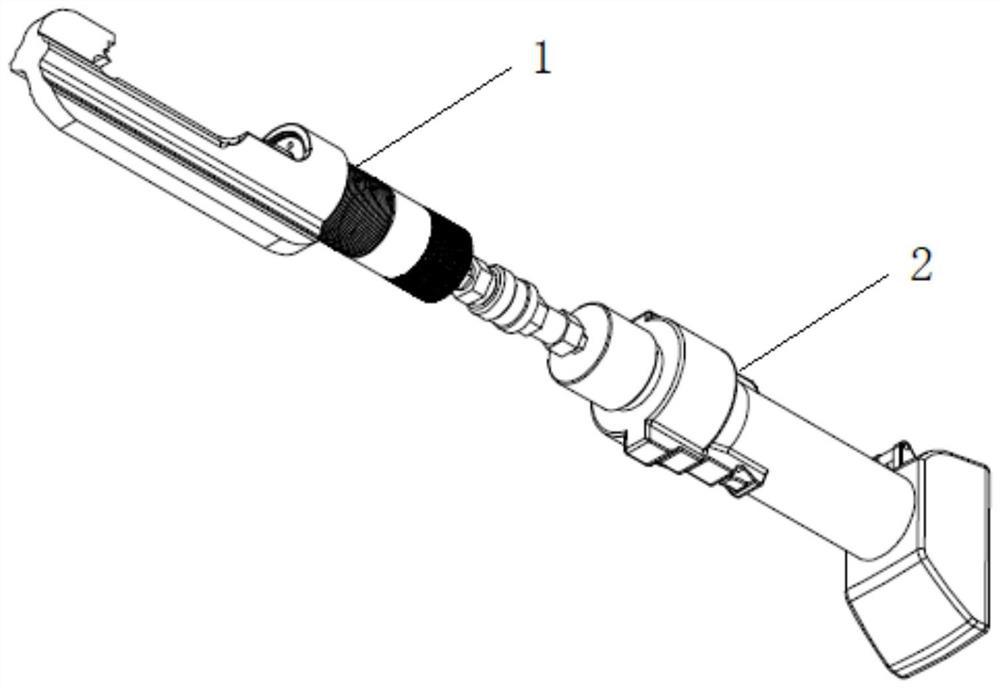

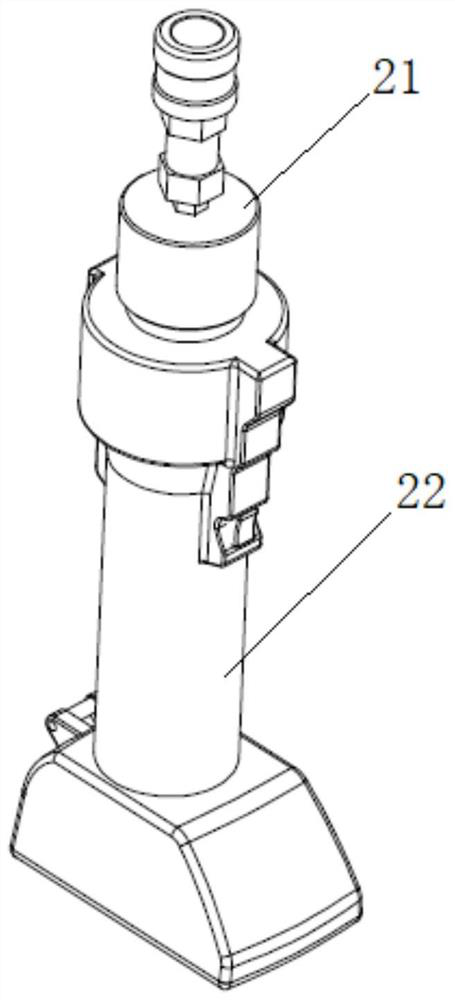

[0020] see Figure 1 to Figure 3 , a hydraulic wedge wire clamp installer of the present invention includes a wire clamp mounting base 1 and an electro-hydraulic power system 2 .

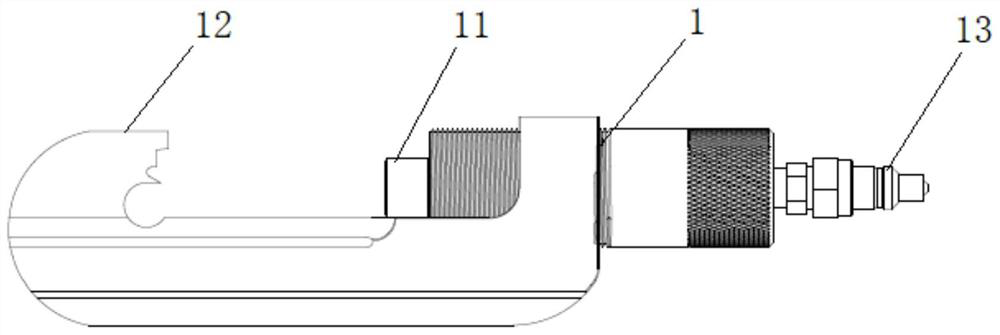

[0021] see figure 1 1. On the top of the wire clamp mounting base 1, a push rod 11 and a hook-shaped wire clamp clamp 12 are provided, and the push rod 11 and the hook-shaped wire clamp clamp 12 form a clamping structure for the C-shaped wire clamp. The hook-type wire clamp clamp 12 is threaded on the top of the wire clamp mounting bracket 1, so that its relative position with the push rod 11 can be adjusted to adapt to different cables, wire clamp models and different installation angles. The inside of the hook-shaped structure of the hook-shaped wire clamp fixture 12 is provided with an irregular tooth-shaped structure, which is used to caus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com