Rubbish leachate biological nitrogen removal process and device

A technology for landfill leachate and biological denitrification, which is applied in the field of high-concentration organic sewage treatment processes and devices, can solve the problems of many experimental studies and few practical applications, and achieves simplified treatment process, avoidance of secondary pollution, and removal of strong ammonia nitrogen. effect of function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

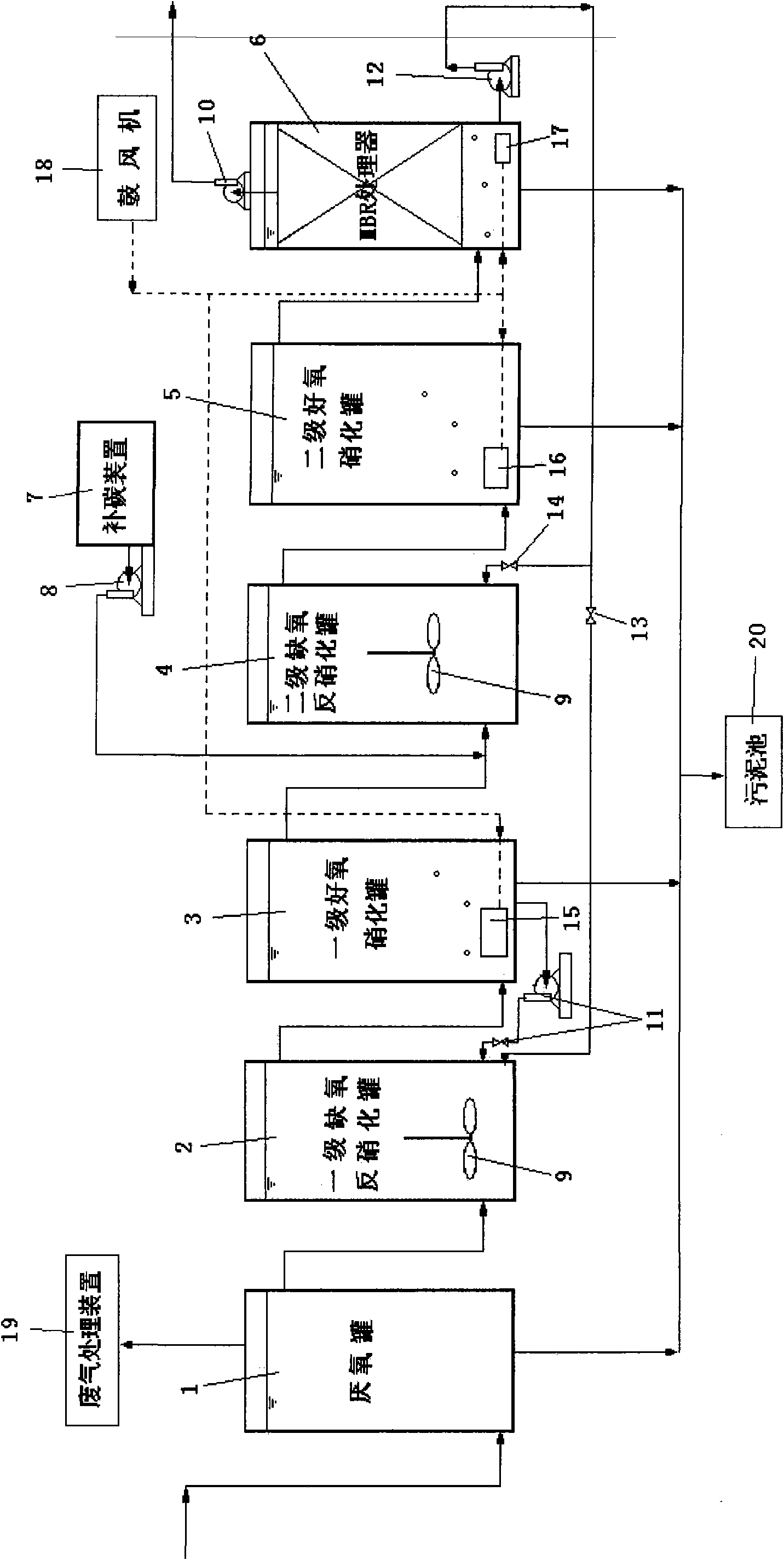

[0043] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

[0044] Such as figure 1As shown, in the GB16889-1997 "Standards for Pollution Control of Domestic Waste Landfill", the biological denitrification process of landfill leachate generally adopts the first-level denitrification to meet the standard requirements. The basic process is: anaerobic biochemical → anoxic reaction Nitrification→aerobic nitrification→MBR treatment→subsequent (nanofiltration membrane) treatment, namely:

[0045] 1) Use a pump to send the landfill leachate into the anaerobic tank for anaerobic biochemical treatment;

[0046] 2) Deodorize the biogas generated during the anaerobic biochemical treatment, recycle it or ignite it, and discharge the sludge generated during the anaerobic biochemical treatment;

[0047] 3) Perform anoxic denitrification treatment → aerobic nitrification treatment → MBR membrane treatment on the effluent a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com