Novel antistatic acrylic fiber and preparation method of antistatic acrylic fiber

An antistatic and manufacturing method technology, applied in the direction of conductive/antistatic filament manufacturing, wet spinning, etc., can solve the problems of fiber mechanical properties decline, fiber spinnability reduction, etc., to improve electrical conductivity, simplify manufacturing process, The effect of improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

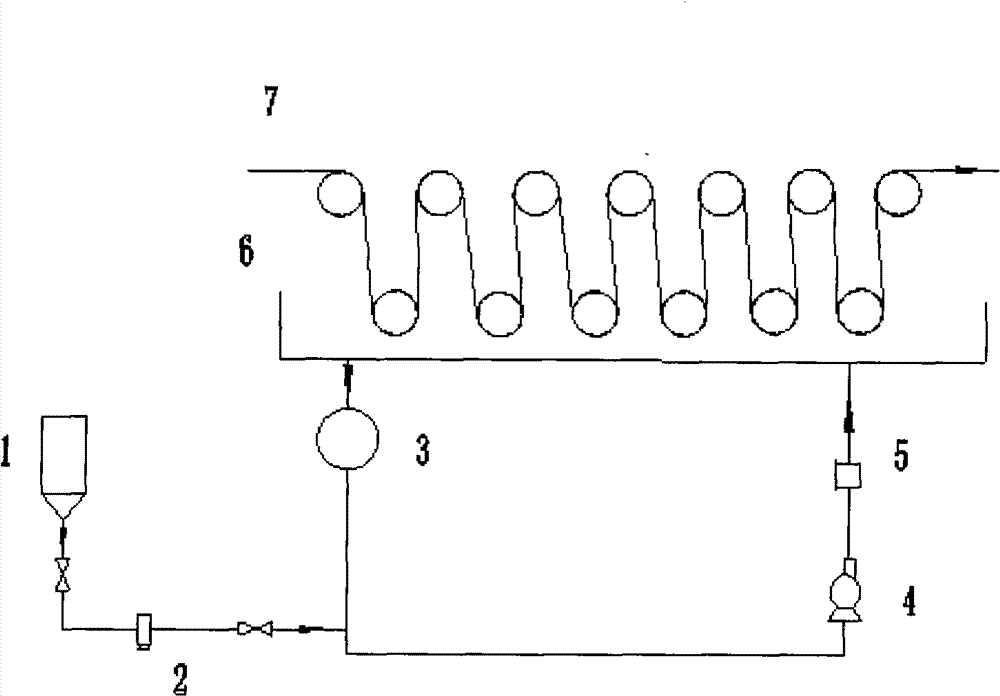

[0032] as attached figure 1 As shown, it is a schematic diagram of an antistatic acrylic fiber processing technology. The acrylic fiber is spun into acrylic fiber by a wet spinning method. The number average molecular weight of the polyacrylonitrile is 5 to 100,000, and the carbon nanotubes are sequentially prepared through an antistatic agent. Tank 1, metering pump 2, and then the circulation pump 4 and filter 5 reach the coagulation bath 6, and then return to the antistatic agent tank 3 and continue to be transported by the circulation pump 4 to form an antistatic agent circulation system. The acrylic fiber spinning stock solution is extruded from the spinneret hole to form a thin stream, and is coagulated into a primary fiber through a coagulation bath 6 containing carbon nanotubes with a rotating drum 7, wherein the carbon nanotubes account for 20% by weight of the coagulation bath, The diameter of the carbon nanotube is 1nm, the length is 2 microns, and the number of the ...

Embodiment 2

[0034] as attached figure 1 As shown, it is a schematic diagram of an antistatic acrylic fiber processing technology. The acrylic fiber is spun into acrylic fiber by a wet spinning method. The number average molecular weight of the polyacrylonitrile is 5 to 100,000. The antistatic agent preparation tank 1, the metering pump 2, the circulation pump 4 and the filter 5 reach the coagulation bath 6, and then return to the antistatic agent tank 3 and continue to be transported by the circulation pump 4, forming an antistatic agent circulation system. The acrylic fiber spinning dope is extruded from the spinneret hole to form a thin stream, and is coagulated into a primary fiber through a coagulation bath 6 containing carbon nanotubes and carbon black with a rotating drum 7, wherein the weight percentage of the carbon nanotubes in the coagulation bath is 25%, carbon nanotube diameter is 20nm, and length is 4 microns, and the tube wall number of carbon nanotube is 10, and carbon blac...

Embodiment 3

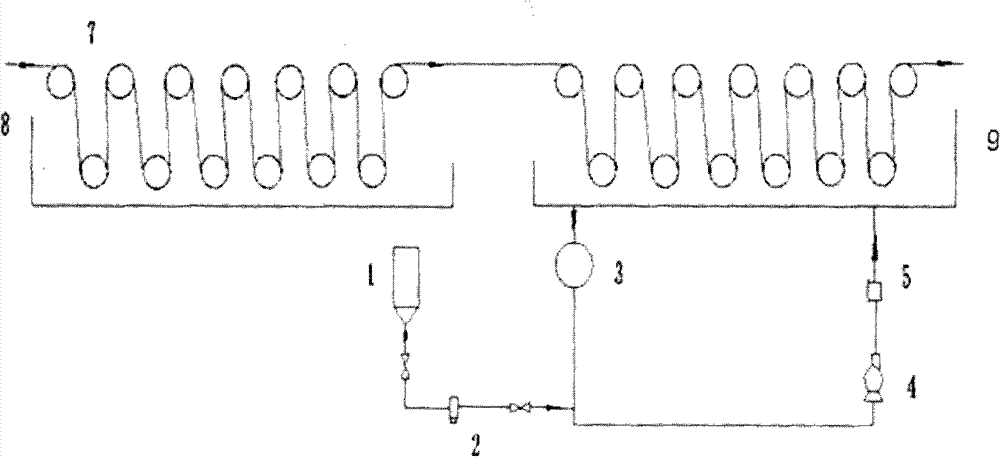

[0036] as attached figure 2As shown, it is a schematic diagram of an antistatic acrylic fiber processing technology. The acrylic fiber is spun into acrylic fiber by a wet spinning method. The number average molecular weight of the polyacrylonitrile is 5 to 100,000. Extrude to form a fine stream, and pass through the coagulation bath and the rotating drum 7 to solidify and form as-spun fibers. The coagulation bath includes two parts, the first coagulation bath 8 and the second coagulation bath 9 containing an antistatic agent, and the carbon nanotubes pass through in turn. The antistatic agent preparation tank 1, the metering pump 2, and then the circulation pump 4 and the filter 5 reach the second coagulation bath 9, and then return to the antistatic agent tank 3 and continue to be transported by the circulation pump 4, forming an antistatic agent circulation system. The first coagulation bath is an aqueous solution containing 10% polyacrylonitrile by weight, and the temperat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com