Modified activated carbon, modifying method and application of modified activated carbon

A technology of activated carbon and activated carbon column, applied in the field of chemical engineering, can solve environmental pollution and other problems, achieve the effect of solving environmental pollution problems and increasing adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

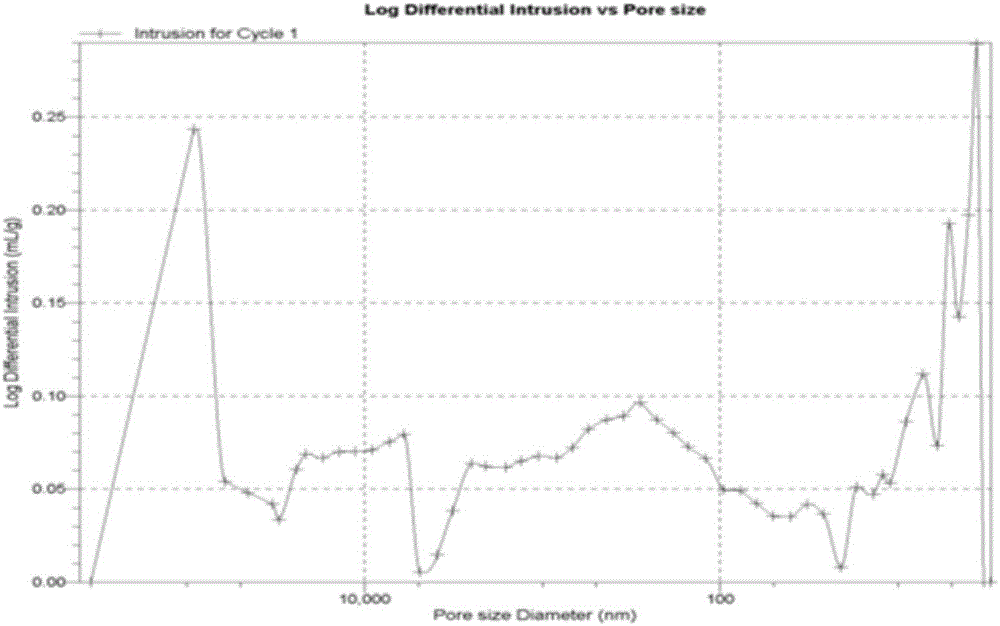

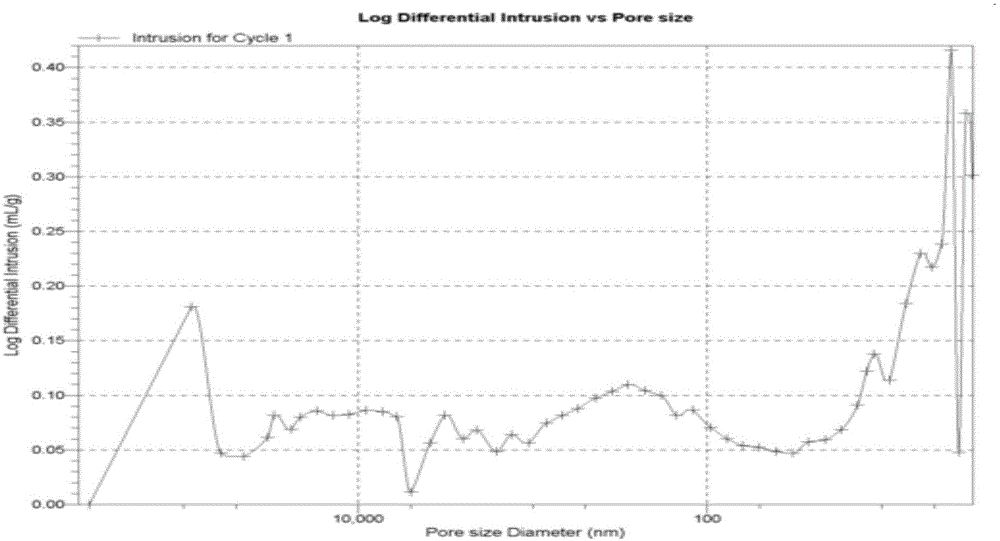

Image

Examples

Embodiment 1

[0028] (1) Activated carbon modification treatment: Take 2 g of activated carbon with a particle size of 0.5-1.0 mm, dry it at 105 ° C to constant weight, and completely immerse it in saturated copper sulfate solution for modification after cooling to room temperature. The modification time is 1 h. After impregnation, dry again at 105°C to constant weight.

[0029] (2) Water-carrying treatment of modified activated carbon: take 2 g of modified activated carbon, and perform steam atomization treatment on it, so that the water-carrying rate of activated carbon is 7%.

[0030] (3) Preparation of modified activated carbon column: Fill the water-carrying modified activated carbon into a glass tube with a length of 20 cm and a diameter of 6 mm*9 mm to prepare a modified activated carbon column, and plug both ends of the column with absorbent cotton.

[0031] (4) Desulfurization by modified activated carbon: desulfurize the biogas containing hydrogen sulfide concentration of 500-750p...

Embodiment 2

[0035] (1) Activated carbon modification treatment: Take 2 g of activated carbon with a particle size of 0.5-1.0 mm, dry it at 105 ° C to constant weight, and completely immerse it in saturated copper sulfate solution for modification after cooling to room temperature. The modification time is 2 hours. After impregnation, dry again at 105°C to constant weight.

[0036] (2) Water-carrying treatment of modified activated carbon: take 2 g of modified activated carbon, and perform steam atomization treatment on it, so that the water-carrying rate of activated carbon is 10%.

[0037] (3) Preparation of modified activated carbon column: Fill the water-carrying modified activated carbon into a glass tube with a length of 20 cm and a diameter of 6 mm*9 mm to prepare a modified activated carbon column, and plug both ends of the column with absorbent cotton.

[0038] (4) Desulfurization by modified activated carbon: desulfurize the biogas containing hydrogen sulfide concentration of 500...

Embodiment 3

[0041] (1) Activated carbon modification treatment: Take 2 g of activated carbon with a particle size of 0.5-1.0 mm, dry it at 105 ° C to constant weight, and completely immerse it in saturated copper sulfate solution for modification after cooling to room temperature. The modification time is 3 hours. After impregnation, dry again at 105°C to constant weight.

[0042] (2) Water-carrying treatment of modified activated carbon: take 2 g of modified activated carbon, and perform steam atomization treatment on it, so that the water-carrying rate of activated carbon is 15%.

[0043] (3) Preparation of modified activated carbon column: Fill the water-carrying modified activated carbon into a glass tube with a length of 20 cm and a diameter of 6 mm*9 mm to prepare a modified activated carbon column, and plug both ends of the column with absorbent cotton.

[0044] (4) Desulfurization by modified activated carbon: Desulfurize the biogas containing hydrogen sulfide concentration of 500...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com