Microwave aftertreatment modifying method for polymer precursor-derived ceramics

A technology of precursors and polymers, applied in the field of microwave post-treatment modification of polymer precursors and ceramics, to avoid oxidation, realize volume heating, and promote mass transfer.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0035] A microwave post-treatment modification method for polymer precursor ceramics in this embodiment includes the following steps:

[0036] 1) in N 2 Under protection, mix polysilazane and thermosetting agent at a mass ratio of 95:5, and stir at 80°C for 1 hour to obtain a mixture; the structure of polysilazane is shown in Formula 1; the thermosetting agent is diisoperoxide Propylbenzene;

[0037] 2) Under vacuum conditions, solidify the mixture obtained in step 1) in a scintillation vial at 140°C for 3 hours to obtain a cured product; after milling the cured product with a high-energy ball mill for 30 min, press it into a circle with a diameter of 20 mm and a thickness of about 2.4 mm piece;

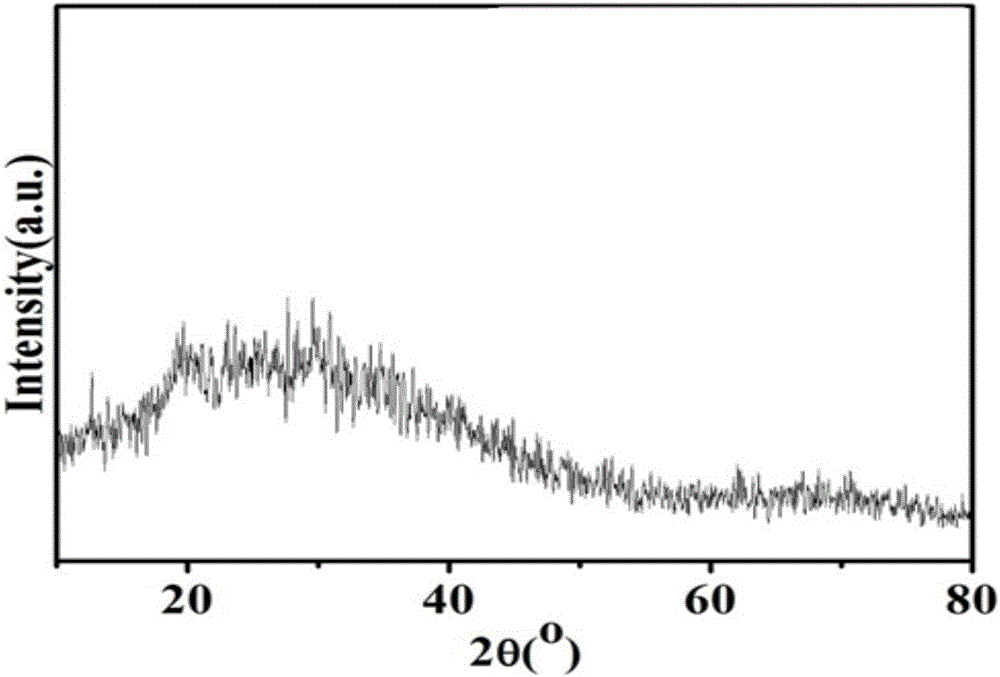

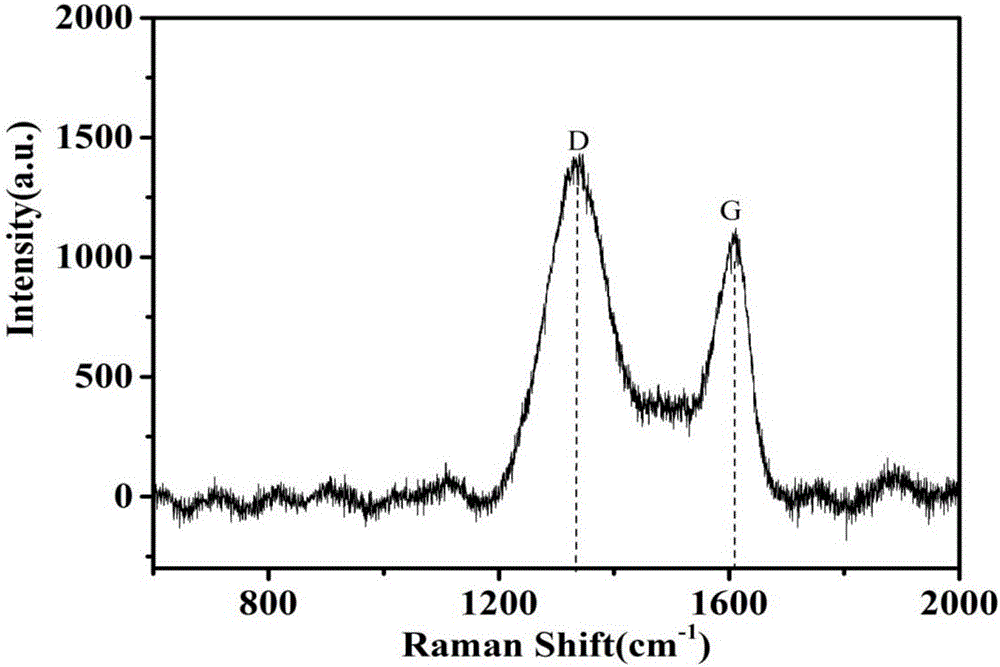

[0038] 3) Under the protection of nitrogen, place the wafer in a tube furnace and pyrolyze it at 1000°C for 4 hours to obtain a precursor ceramic;

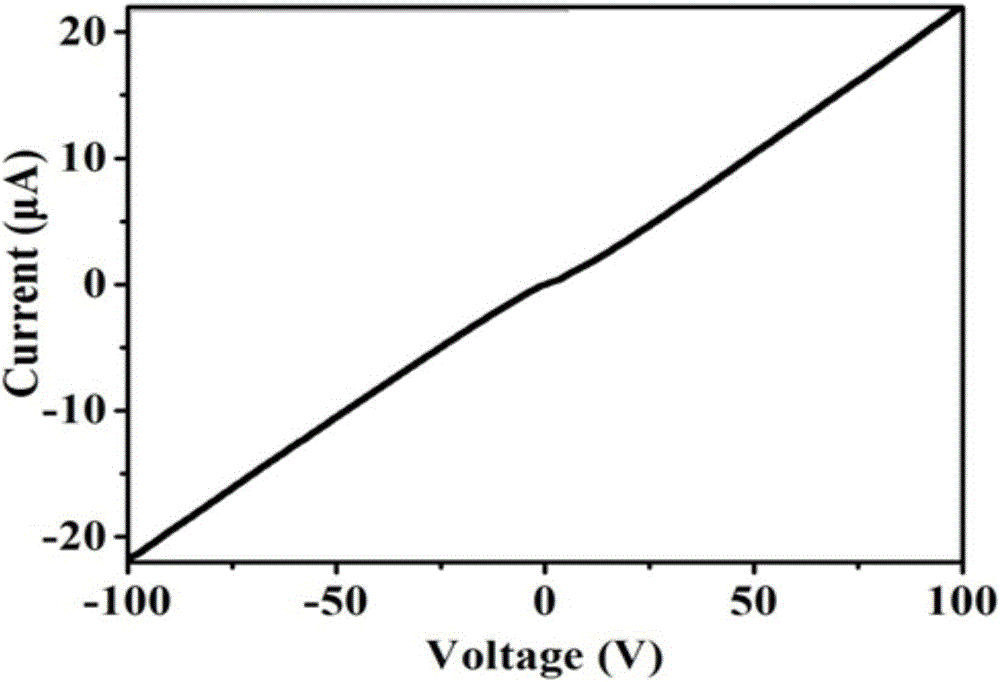

[0039] 4) Under the protection of nitrogen, put the precursor ceramics in the heat preservation device, put them into the microwave ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com