Biodegradation method of methyl tert-butyl ether in ground water

A technology of methyl tert-butyl ether and biodegradation, applied in the direction of contaminated groundwater/leachate treatment, water pollutants, sustainable biological treatment, etc., can solve problems such as limited lifespan, and achieve low cost and high oxygen release rate Gentle, high total oxygen release effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] Embodiment 1 Preparation of permeable bioreaction grid and its application in degrading MTBE in groundwater

[0057] 1.1 Materials and instruments

[0058] Calcium peroxide: industrial grade, 40% purity, the main impurity is Ca(OH) 2 (Tianjin Chilong Chemical Co., Ltd.);

[0059] Bentonite: Natural bentonite produced in Lin'an;

[0060] Sand: natural river sand, particle size less than 2mm;

[0061] Cement: 325# ordinary slag portland cement;

[0062] NH 4 Cl: industrial grade;

[0063] K 3 PO 4 : Industrial grade;

[0064] Microorganisms: Microbial sources obtained from the oily soil of a gasoline-contaminated site in Hebei Province, using glucose as a carbon source, and obtained after cultivation.

[0065] 1.2 Permeable bioreaction grid

[0066] Weigh bentonite / CaO 2 / cement / sand (or fly ash) / water (mass percentage: 10:20:25:15:30) is placed in a container and stirred evenly; then the resulting mixture is made into cubes with a side length of 3cm, Air dry un...

Embodiment 2

[0069] Example 2 Performance Research of Concrete Materials Containing Oxygen-releasing Compounds

[0070] 2.1 Materials and Instruments

[0071] Calcium peroxide: industrial grade, 40% purity, the main impurity is Ca(OH) 2 (Tianjin Chilong Chemical Co., Ltd.);

[0072] Bentonite: Natural bentonite produced in Lin'an;

[0073] Sand: natural river sand, particle size less than 2mm;

[0074] Cement: 325# ordinary slag portland cement;

[0075] JJ-4A six-connected electric mixer.

[0076] 2.2 Preparation of two different concrete materials

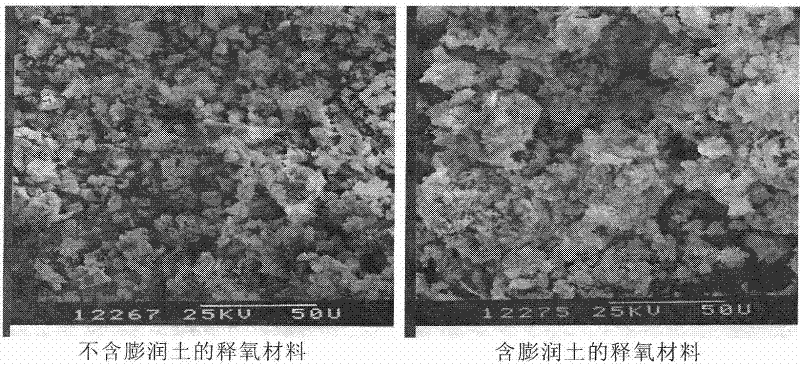

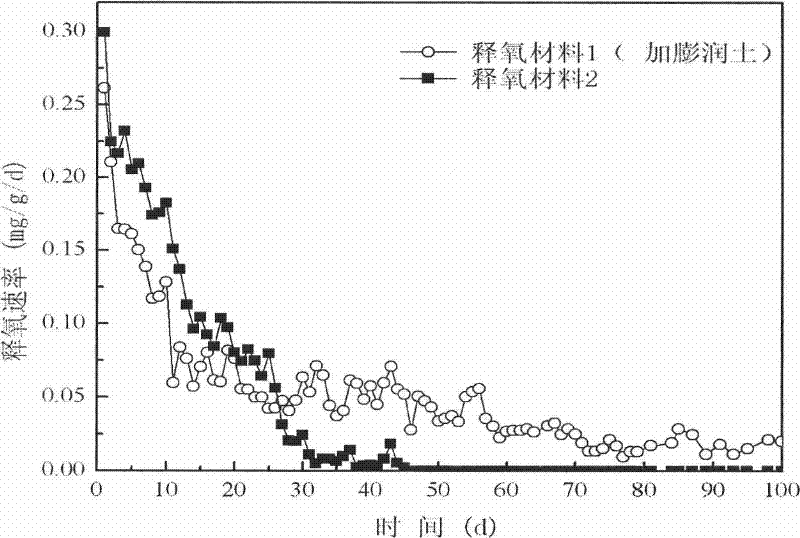

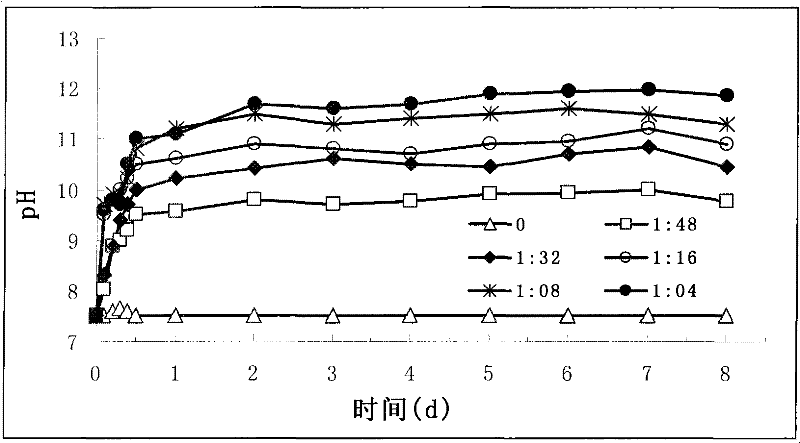

[0077] 2.2.1 Preparation of concrete material 1 (without bentonite)

[0078] As shown in Table 1-1, weigh the set ratio of CaO 2 / cement / sand / water is placed in a container and stirred evenly (water can be tap water), made into cubes with a side length of 3cm, and air-dried under natural conditions.

[0079] 2.2.2 Preparation of concrete material 2 (including bentonite)

[0080] (1) As shown in Table 1-1, weigh calcium peroxide and b...

Embodiment 3

[0101] Example 3 Performance Research on Bioreaction Grid for Degrading MTBE

[0102] 3.1 Experimental instruments and materials

[0103] Oily soil: taken from a gasoline-contaminated site in Hebei;

[0104] Sand: natural river sand, particle size less than 2mm;

[0105] Oxygen-releasing material: oxygen-releasing material 2 prepared in Example 2;

[0106] Groundwater: taken from the self-prepared well of China University of Geosciences (see Table 1 for composition), pH=7.38;

[0107] Glucose: Beijing Beihua Fine Chemicals Co., Ltd.;

[0108] Sodium azide (NaN 3 ): Tianjin Yuanli Chemical Co., Ltd. (analytical pure);

[0109] Methyl tert-butyl ether (MTBE): imported chromatographically pure (US Tedia Company), content> 99%;

[0110] Tert-butanol (TBA): imported chromatographically pure (USA Tedia Company), content > 99%;

[0111] Acetone (acetone): imported chromatographically pure (U.S. Fisher Company), content> 99%;

[0112] Purified water: commercially available 550...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com