Solid combination switch device

A compound switch and solid-state technology, applied in reactive power compensation, reactive power adjustment/elimination/compensation, etc., can solve problems such as arcing, poor real-time performance of reactive power compensation, thyristor breakdown and burning, etc., to reduce the number of switching times, The overall structure is simple and the effect of increasing the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

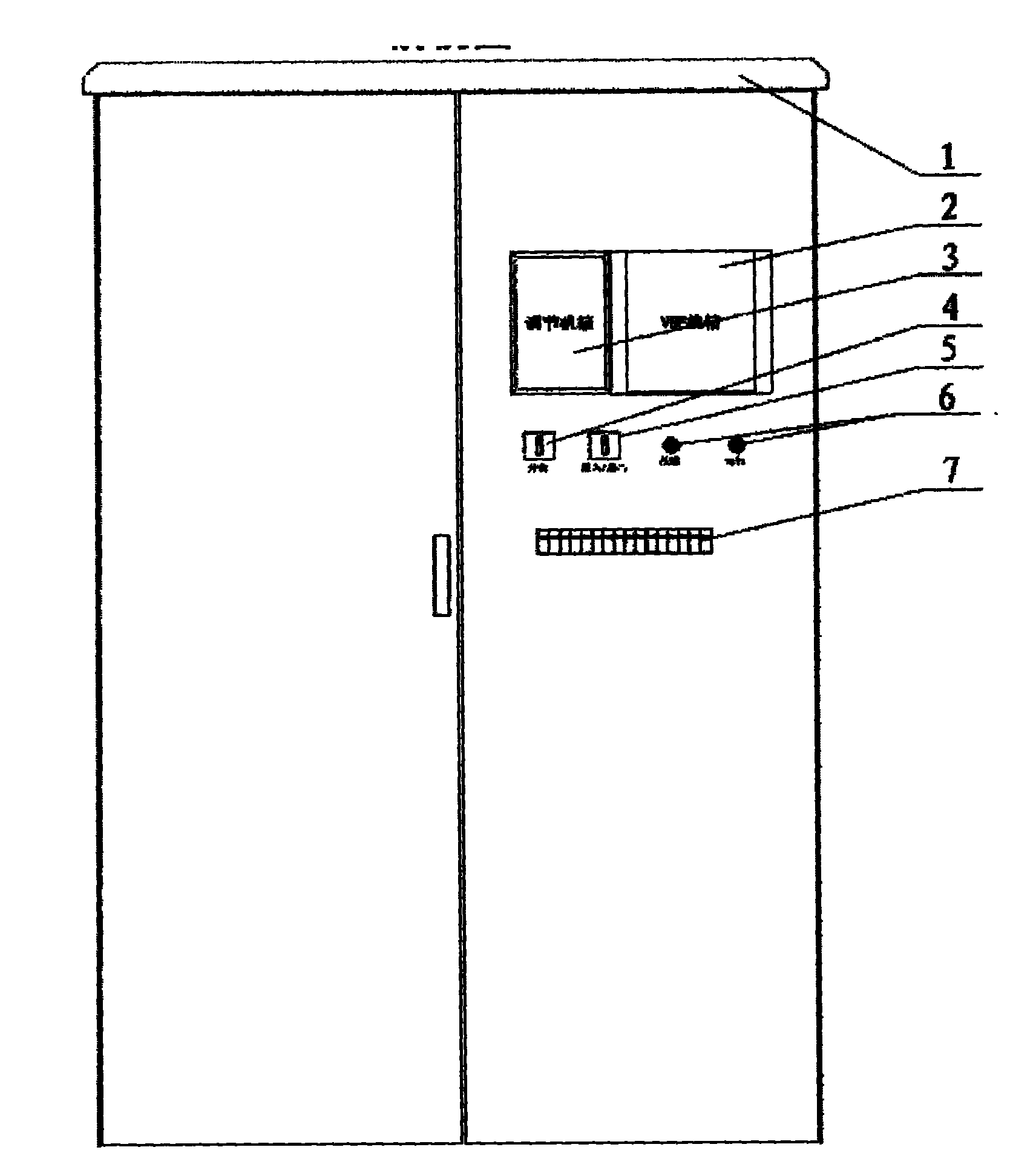

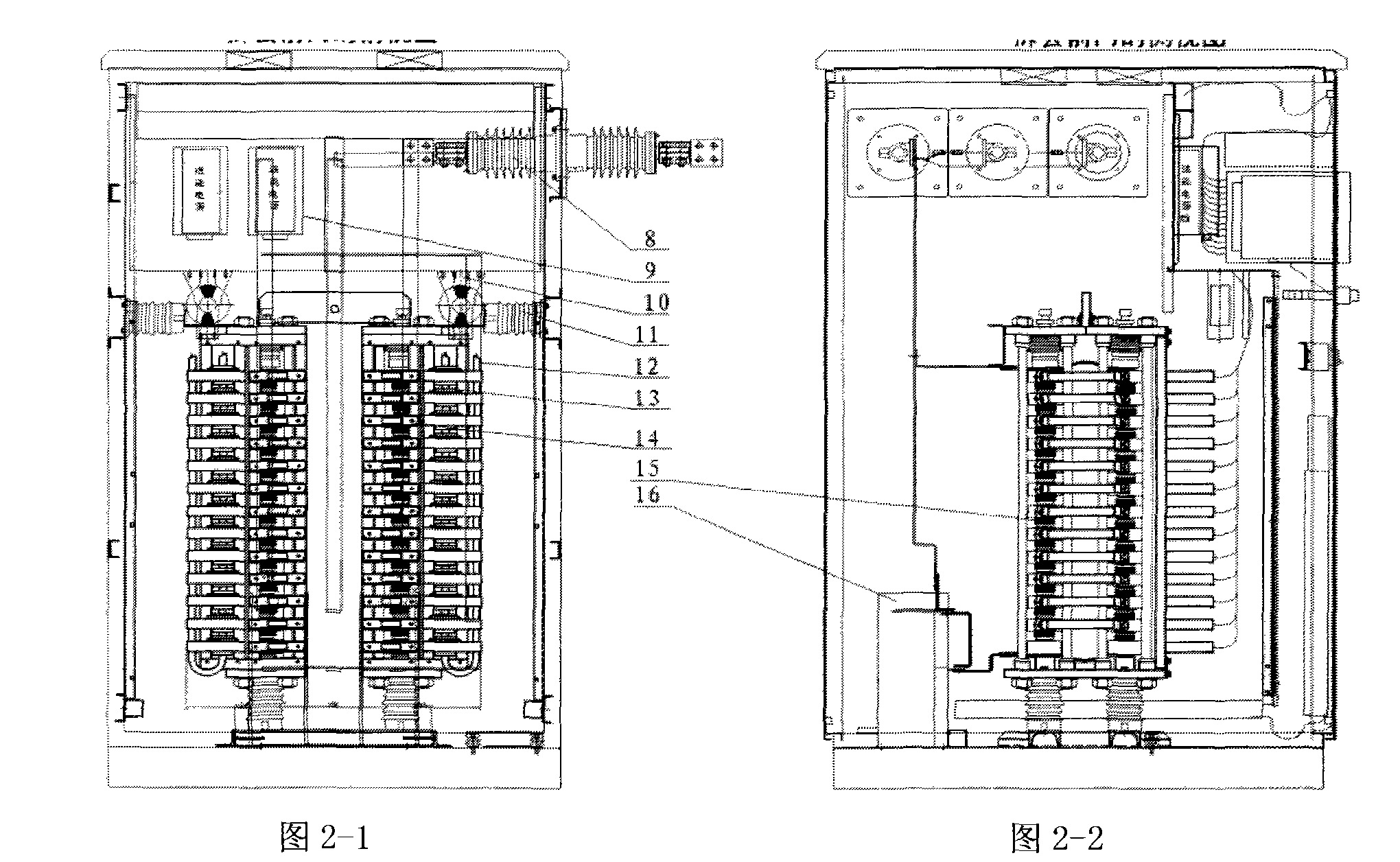

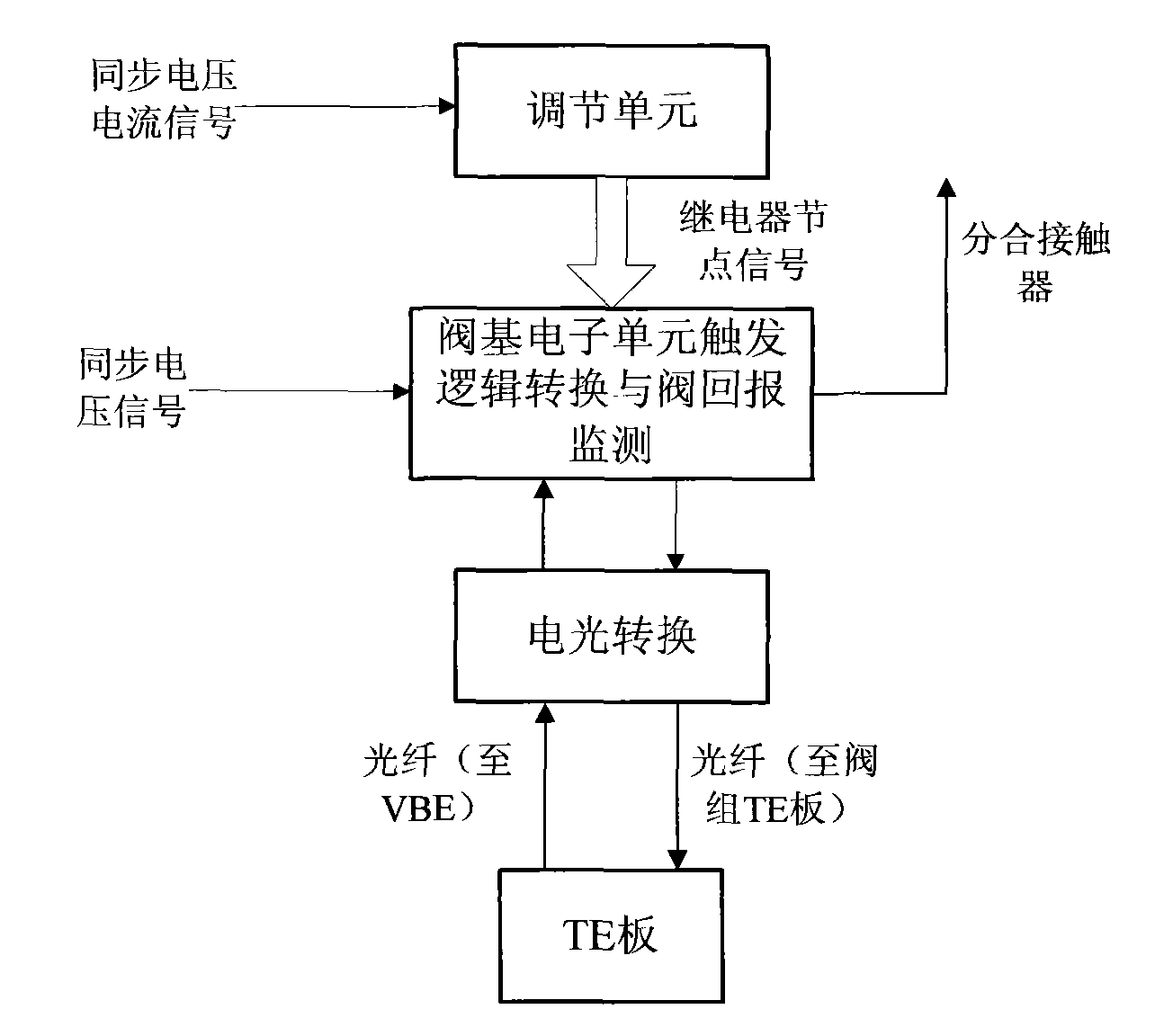

[0022] Next, the solid-state composite switch device of the present invention will be further described in conjunction with the accompanying drawings.

[0023] The solid-state composite switchgear of the present invention is installed in a power distribution cabinet as a whole, including a two-phase thyristor valve string, a three-phase contactor, a thyristor trigger board, a thyristor trigger board energy-sending inverter power supply, a high-frequency converter, and a step-up transformer , adjustment unit, valve base electronic unit, trigger and return optical fiber, working status wrench, contactor opening and closing wrench, AC and DC air switch, contactor opening and closing indicator light.

[0024] According to different voltage levels, the solid-state composite switchgear is divided into a high-voltage primary system part and a low-voltage secondary system part. Primary system solution: In a cuboid distribution cabinet, the three-phase voltage is connected to the bus b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com