Impregnation method of non-woven fabric

A technology of non-woven fabrics and base fabrics, applied in textiles and papermaking, fiber types, fiber treatment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

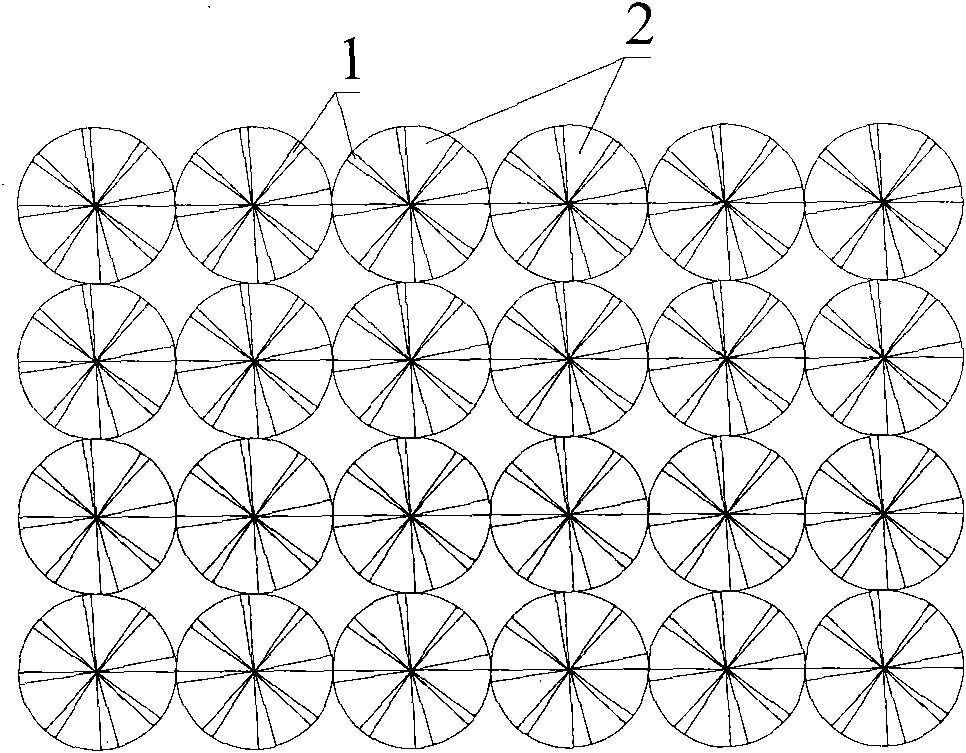

Image

Examples

Embodiment 1

[0053] 1. Preparation of bicomponent composite fibers:

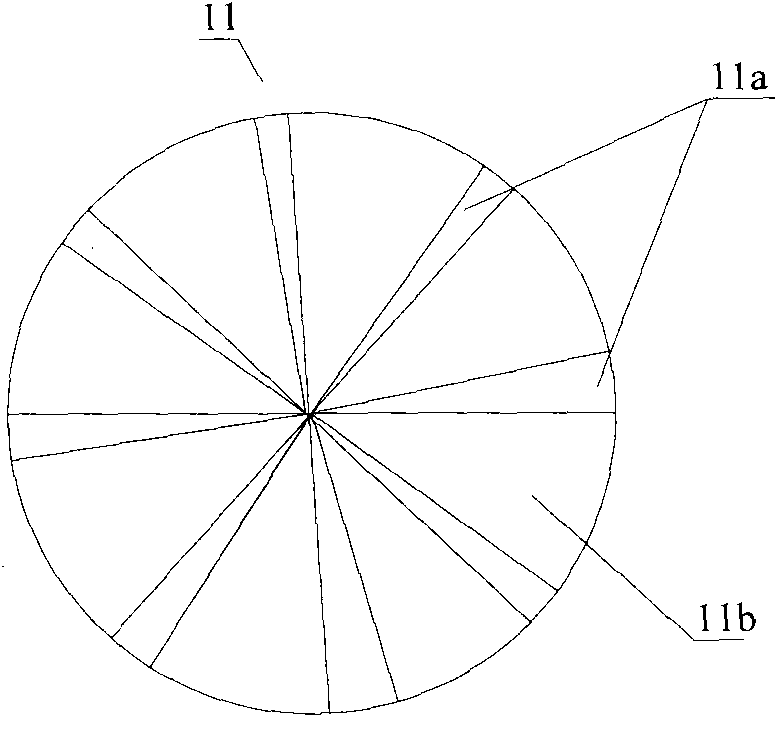

[0054] Take 25 parts of polyethylene terephthalate slices and put them into a polyester spinning screw extruder to melt and knead at 280 °C; take 75 parts of polycaprolactam chips into a polyamide spinning screw extruder to melt at 280 °C kneading. The mixed products of two screw extruders were subjected to figure 2 The 8-split spinneret shown is extruded, and the following examples all use this spinneret extrusion molding to obtain 8-split as-spun fibers, and the as-spun fibers are filled between the fiber skeleton and the fiber skeleton. The lobes between the fibers are composed of polyethylene terephthalate and the lobes are polycaprolactam;

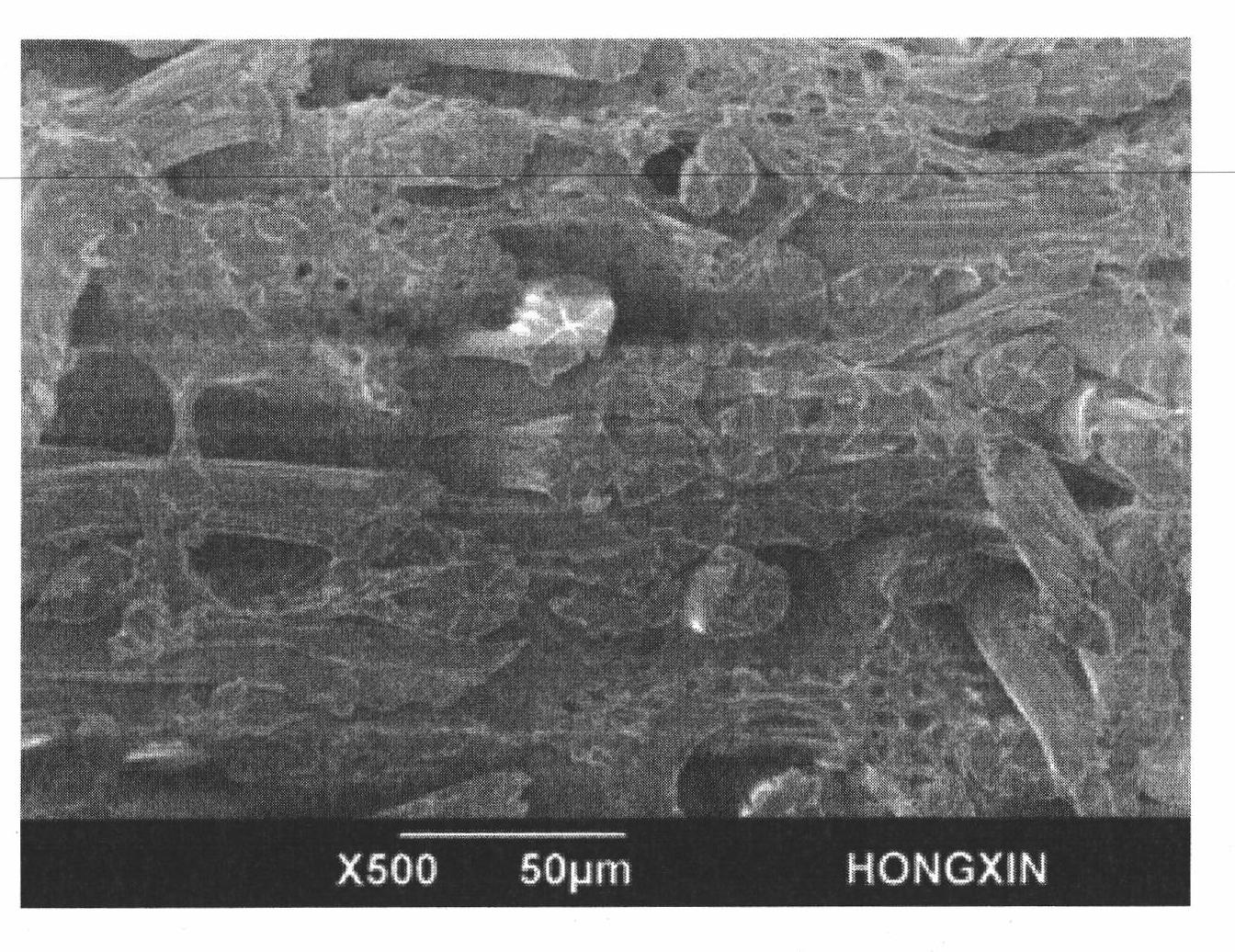

[0055] The as-spun fibers were stretched sequentially by 1.8 times and 1.7 times, oiled with 4wt% silicone oil, and heat-set at 70°C to obtain composite fibers, then cut into composite fibers of 50mm, and sampled the composite fibers The tests were carried out and the result...

Embodiment 2

[0066] 1. Preparation of split-type composite fibers:

[0067] In this example, 28 parts of polybutylene terephthalate chips and 72 parts of polyhexamethylene adipamide chips are taken as spinning raw materials, and the rest of the preparation process is the same as in Example 1. The backbone component is polybutylene terephthalate, and the split component is polyhexamethylene adipamide. The composite fiber was sampled and tested, and the results are listed in Table 1.

[0068] 2. Preparation of non-woven fabric:

[0069] Unpack the split-type composite fiber obtained in step 1, card and needle punch it to make a density of 0.24g / cm 3 , Gram weight is 565h / cm 2 The non-woven fabrics, the measured properties of the non-woven fabrics are listed in Table 2.

[0070] 3. Impregnated non-woven fabric;

[0071] Import the non-woven fabric prepared in step 2 into a PVA impregnating machine for impregnation. The PVA impregnating solution includes: 2.4% polyvinyl alcohol in terms of...

Embodiment 3

[0077] 1. Preparation of split-type composite fibers:

[0078] Take 16 parts of polyethylene terephthalate chips and 0.5 parts of fiber additives and put them into the polyester spinning screw extruder, take 73.5 parts of polycaprolactam chips and put them into the polyamide spinning screw extruder, and put them in the Melt and knead at 275°C, and extrude the kneaded product through a spinneret to obtain 8 lobes of nascent fibers. The nascent fibers are composed of a fiber skeleton and a split part filled between the fiber skeletons. The skeleton part is polyethylene terephthalate, and the split part is polycaprolactam;

[0079] The as-spun fibers were stretched sequentially by 1.6 times and 1.5 times, oiled with 4wt% silicone oil, and heat-set at 70°C to obtain composite fibers, which were then cut into short fibers of 50 mm and sampled for the composite fibers The tests were carried out and the results are listed in Table 1.

[0080] 2. Preparation of non-woven fabric:

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fineness | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com