Method for preparing lead magnesium niobate-lead titanate thick film

A technology of lead magnesium niobate and lead titanate is applied in the field of thick film preparation, which can solve the problems of poor surface compactness of lead magnesium niobate-lead titanate thick film, and achieve the effect of improving surface compactness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

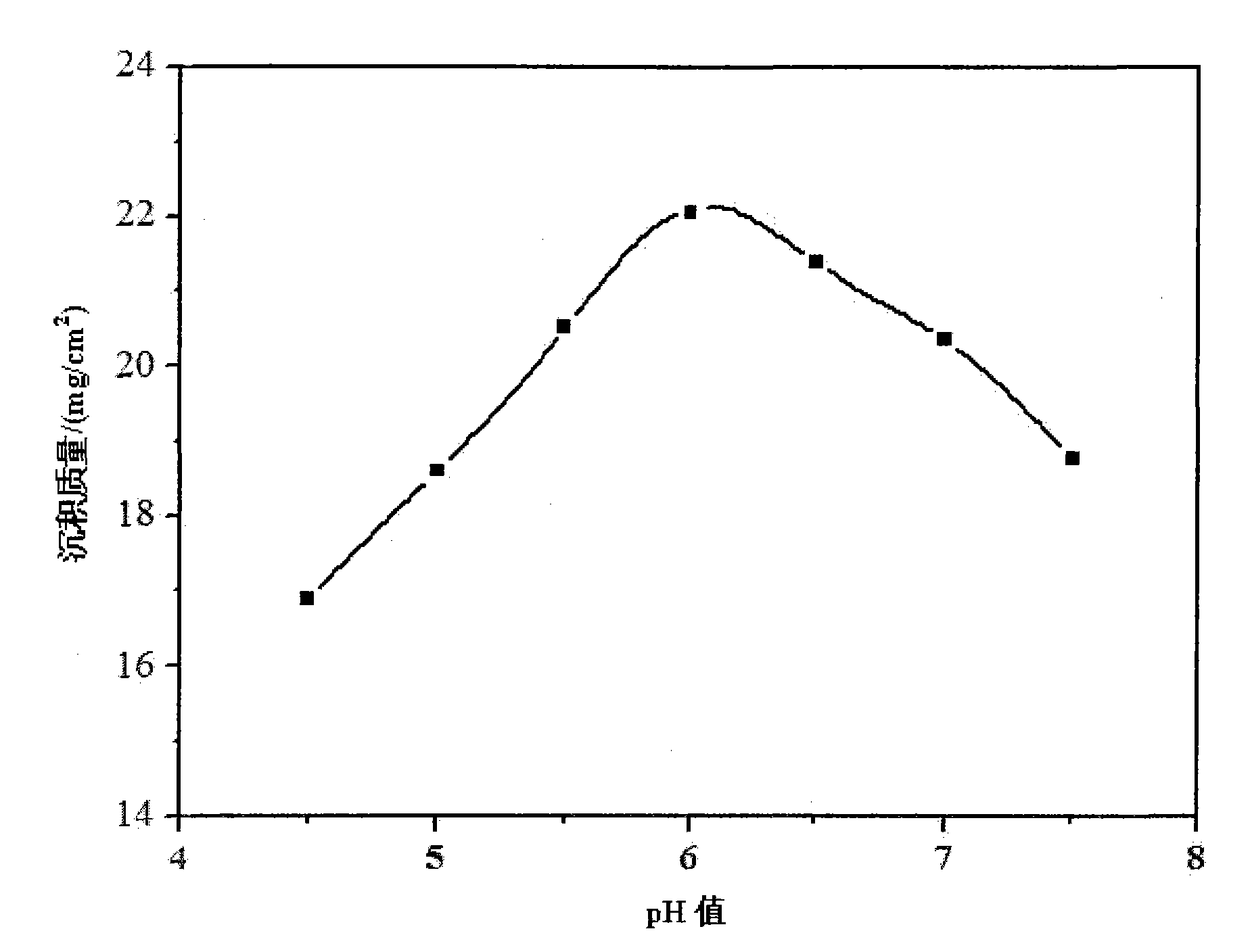

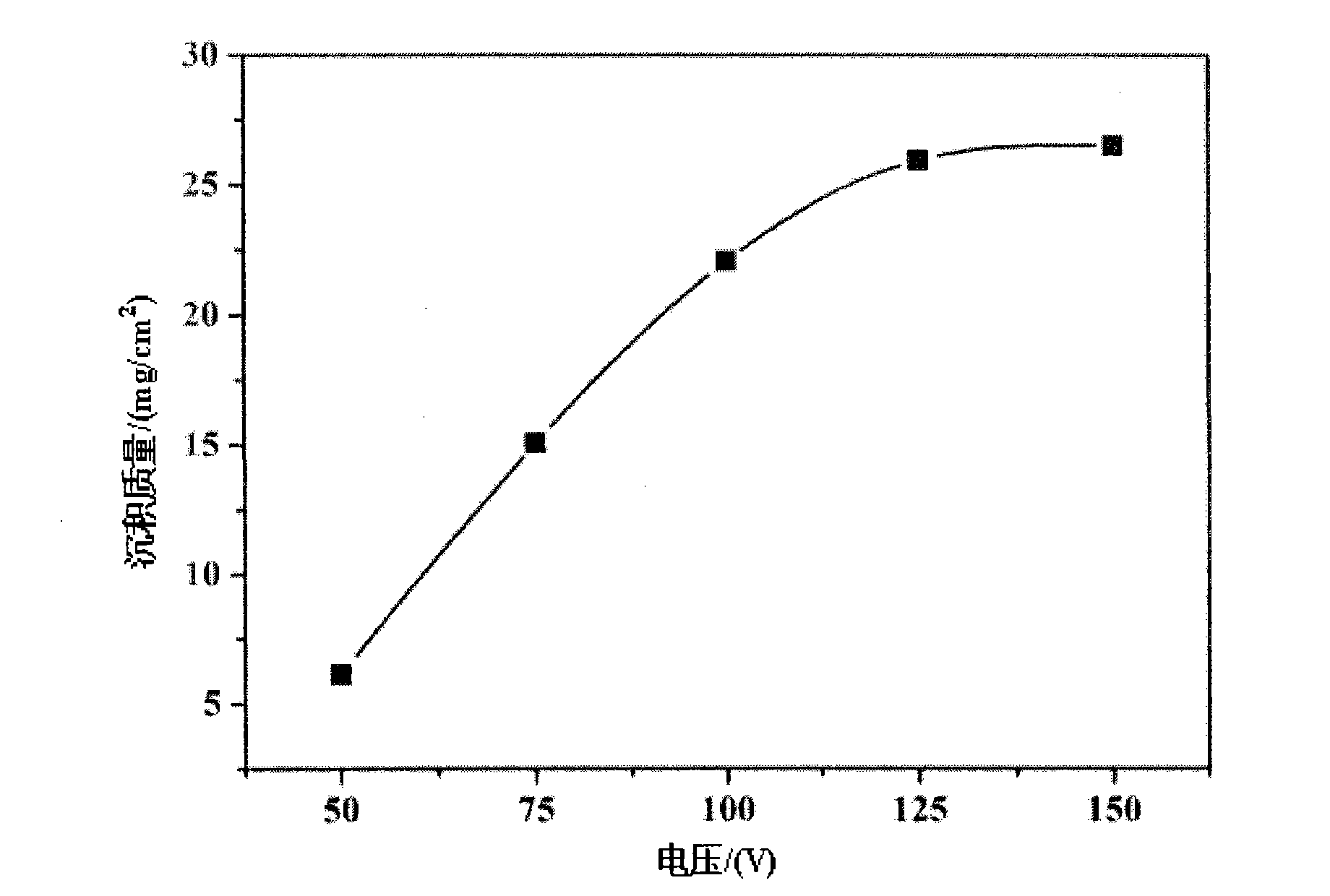

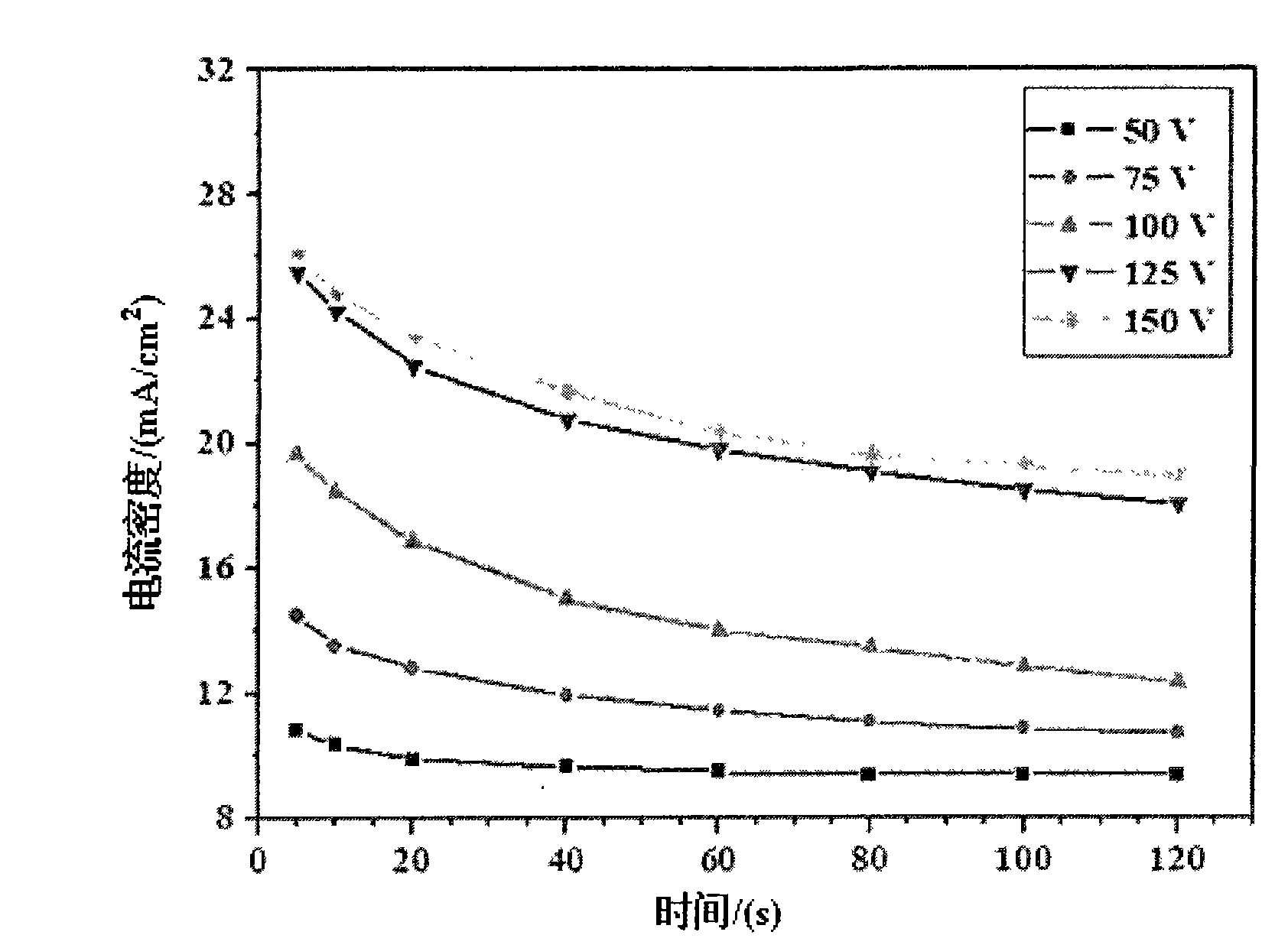

Embodiment 1

[0019] Example 1: Magnesium nitrate hexahydrate was dissolved in deionized water, niobium pentoxide powder was added to its aqueous solution, the mixture was subjected to ultrasonic vibration for 10 minutes and then stirred for 30 minutes to obtain a uniformly mixed suspension; slowly dropwise into the suspension to dilute The pH value of the ammonia water was adjusted to 9, the magnesium hydroxide in the solution was precipitated and adsorbed on the niobium pentoxide particles, and the stirring was continued for 30min; lead oxide powder was added to the solution, and an appropriate amount of titanium dioxide was added according to the stoichiometric ratio. Continue to stir for 60 min and then dry by rotary evaporation; the obtained pale yellow powder is ball-milled with acetone as a medium for 20 h and then dried; the obtained powder is calcined at 500 °C for 3 h; (1-x)Pb( Mg 1 / 3 Nb 2 / 3 )O 3 -xPbTiO3 powder is used as raw material, anhydrous ethanol is used as solvent, plat...

Embodiment 2

[0020] Example 2, magnesium nitrate hexahydrate was dissolved in deionized water, niobium pentoxide powder was added to its aqueous solution, and the mixture was subjected to ultrasonic vibration for 5 minutes and then stirred for 20 minutes to obtain a uniformly mixed suspension; in the suspension, slowly drip into the diluted solution The pH value of the ammonia water was adjusted to 8, the magnesium hydroxide in the solution was precipitated and adsorbed on the niobium pentoxide particles, and the stirring was continued for 20 min; the lead oxide powder was added to the solution, and an appropriate amount of titanium dioxide was added according to the stoichiometric ratio. Continue to stir for 50 min and then dry by rotary evaporation; the obtained pale yellow powder is ball-milled with acetone as a medium for 18 h and then dried; the obtained powder is calcined at 400 °C for 1 h; (1-x)Pb( Mg 1 / 3 Nb 2 / 3 )O 3 -xPbTiO 3 Powder is used as raw material, anhydrous ethanol is ...

Embodiment 3

[0021] Example 3, magnesium nitrate hexahydrate was dissolved in deionized water, niobium pentoxide powder was added to its aqueous solution, and the mixture was subjected to ultrasonic vibration for 20 minutes and then stirred for 50 minutes to obtain a uniformly mixed suspension; in the suspension, slowly dropwise to dilute The pH value of the ammonia water was adjusted to 12, the magnesium hydroxide in the solution was precipitated and adsorbed on the niobium pentoxide particles, and the stirring was continued for 40 min; then lead oxide powder was added to the solution, and an appropriate amount of titanium dioxide was added according to the stoichiometric ratio. Continue to stir for 80 min and then dry by rotary evaporation; the obtained pale yellow powder is ball-milled with acetone as a medium for 24 h and then dried; the obtained powder is calcined at 900 °C for 1 h; (1-x)Pb( Mg 1 / 3 Nb 2 / 3 )O 3 -xPbTiO3 powder is used as raw material, anhydrous ethanol is used as sol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com