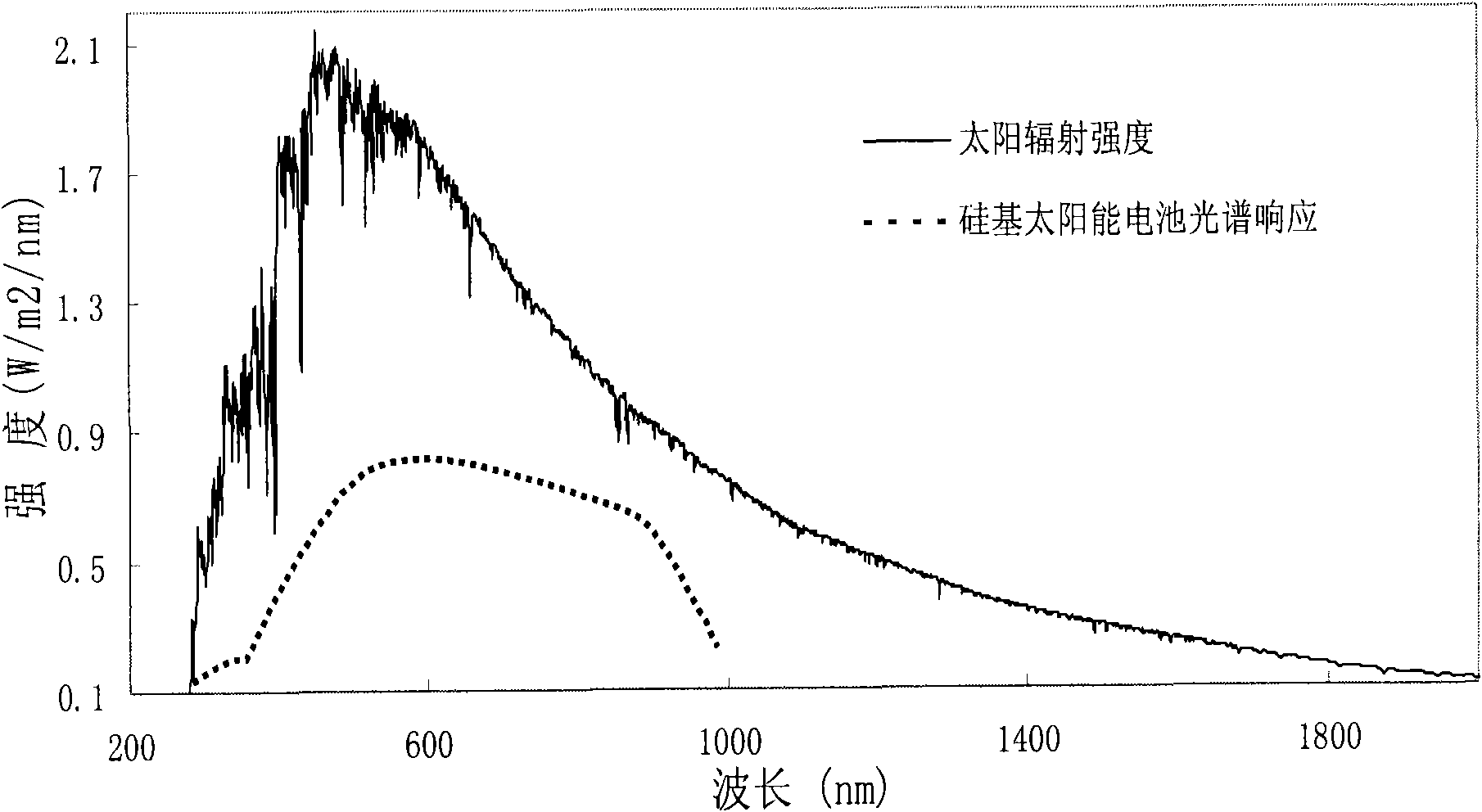

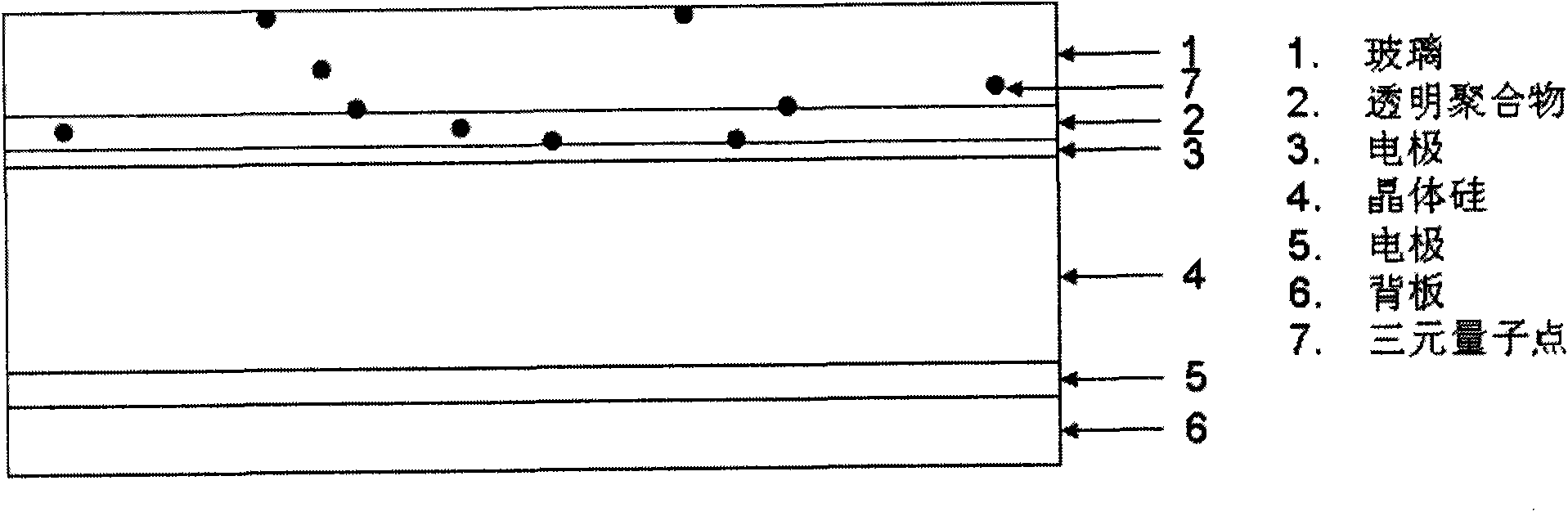

Quantum dot optical wavelength converting layer for solar cell

A technology of solar cells and quantum dots, applied in optics, circuits, photovoltaic power generation, etc., can solve the problems of reduced fluorescence efficiency and stability, limited practical application, etc., and achieve the effects of superior fluorescence stability, improved efficiency, and high fluorescence efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

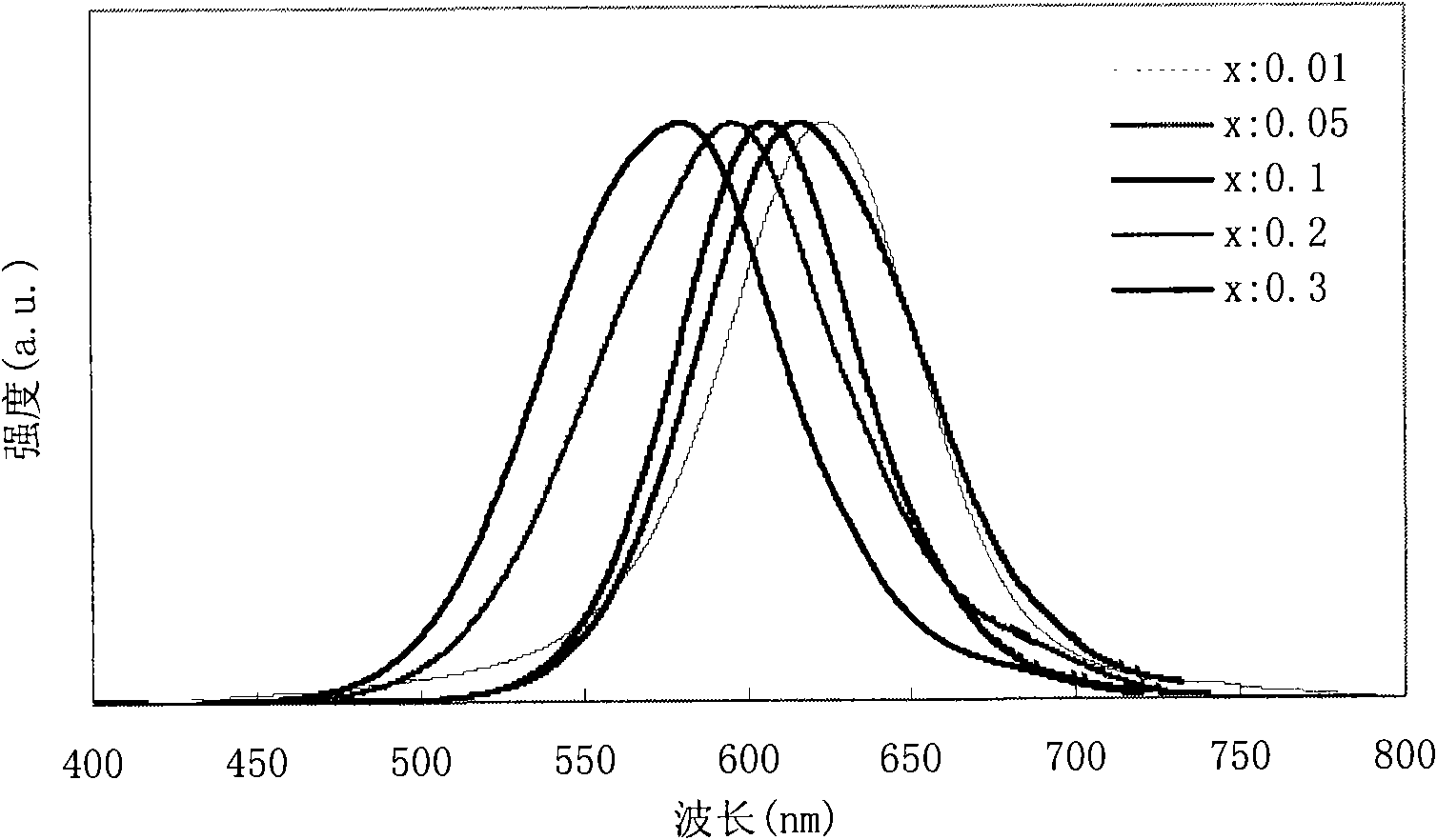

Embodiment 1

[0084] Preparation of ternary alloy quantum dots CdSe 0.2 S 0.8 : Dissolve 2mmol Se and 8mmol S in 10ml trioctylphosphine (TOP) and 10ml octadecene (ODE) under magnetic stirring at room temperature to form a SeS precursor solution; dissolve 10mmol chromium oxide (CdO) in 10ml In oleic acid and 10ml oleylamine, a Cd precursor solution was formed under magnetic stirring at 300°C. The above two precursor solutions with equal volumes were mixed, stirred magnetically, and then heated to 300°C to rapidly nucleate. Then cool down to room temperature, the reaction is quenched, the growth process is interrupted, and CdSe is generated 0.2 S 0.8 Ternary alloy quantum dots, the particle size is about 5nm.

Embodiment 2

[0086] Preparation of ternary alloy quantum dots Zn 0.5 Cd 0.5 S: Dissolve 1 mol of sulfur and 30 μmol of vulcanizing agent in 6 g of octadecene (ODE) and sonicate for 1 hour; Carbene (ODE), then mix the two solutions and transfer them to a three-necked flask, heat to 120°C for 2 hours with magnetic stirring to obtain a clear solution, and then heat to 240°C to generate Zn by thermal annealing under nitrogen atmosphere 0.5 Cd 0.5 S ternary alloy quantum dots, the particle size is about 4nm.

Embodiment 3

[0088] Preparation of ternary alloy quantum dots Zn 0.01 Cd 0.99 Se: A mixed solution of 5 mmol of chromium oxide, 5 ml of octyl phosphonium and 15 ml of tetradecenylphosphonic acid was magnetically stirred at 300° C. for 6 hours, cooled to room temperature and left for 48 hours. Dissolve 5 mmol of selenium in 10 ml of trioctylphosphine. The two solutions were then mixed and heated to 280 °C for 40 min to generate CdSe nanoparticles. Dissolve 50 μmol diethylzinc and 50 μmol selenium in 0.5ml trioctylphosphorus solution, then raise the temperature to 300°C and inject the prepared CdSe nanoparticle solution, heat for 3 hours and then cool down rapidly, dilute with chloroform to form ternary alloy quantum dots Zn 0.01 Cd 0.99 Se, the particle size is about 4nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com