Production method of cobaltous oxide for power battery

A cobaltous oxide and power battery technology, which is applied in cobalt oxide/cobalt hydroxide, battery electrodes, products, etc., can solve the problems of high-performance and high-power power batteries, poor chemical purity, and high production costs. Improve chemical purity and physical properties, excellent chemical and physical indicators, and prolong service life

Active Publication Date: 2010-07-28

周红阳

View PDF0 Cites 1 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

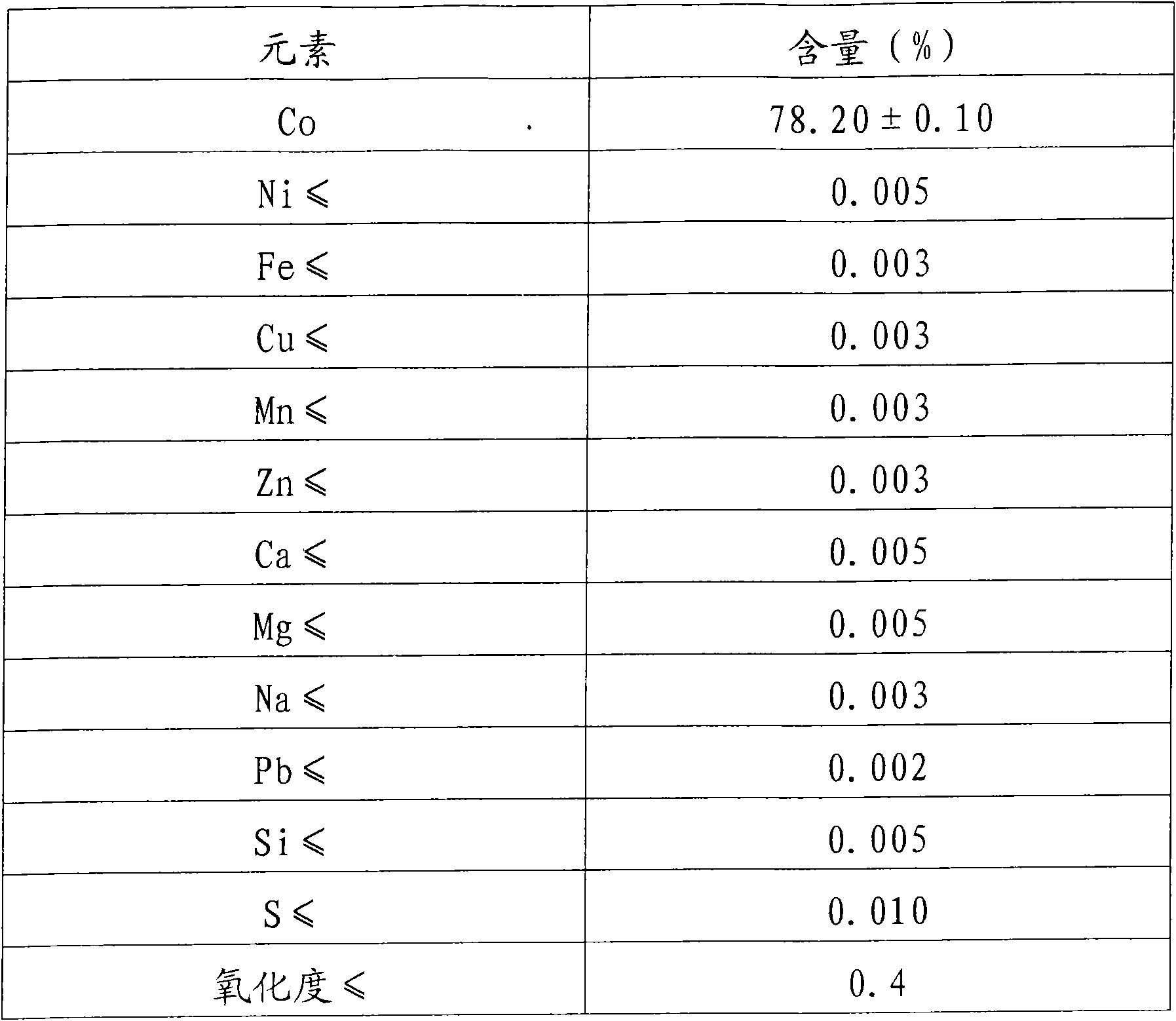

[0002] Although the invention patent "Production Method of Subcobalt Oxide" with publication number 101200309 can produce a kind of cobaltous oxide with high cobalt content, the chemical purity of the product is not good, and the product contains nickel, iron, calcium, copper, manganese, zinc, The content of magnesium and other elements is too high, which cannot meet the requirements of various indicators for high-performance and high-power power batteries for battery materials

In addition, one needs to heat the reaction tank that produces the intermediate product cobalt carbonate and control the temperature to 50-55°C, which requires a lot of energy consumption; the other is to continuously fill the reduction furnace that decomposes and produces cobaltous oxide-hydrogen, And hydrogen is relatively expensive, so this invention patent also has the disadvantage of high production cost

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

[0027] The production steps are the same as above, and will not be repeated here. The inert gas used in this example is nitrogen.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

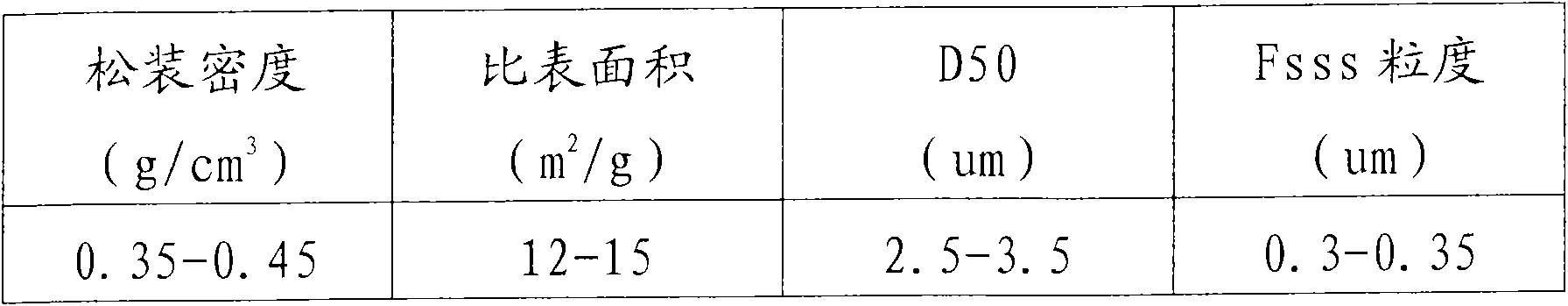

The invention relates to a production method of cobaltous oxide for a power battery, comprising the following steps of: firstly reacting a cobalt chloride solution with an ammonium acid carbonate precipitant through a third-order reaction tank to generate basic cobaltous carbonate slurries; then filtering the slurries, slurrying, washing, drying, and protecting and crashing by an inert gas to obtain basic cobaltous carbonate powder; then decomposing through a positive pressure atmosphere, wherein a decomposing furnace is internally provided with 10 computer temperature control areas, air inside the decomposing furnace is driven by the inert gas before feeding, then a CO2 gas is continuously charged, and a material boat loaded with the basic cobaltous carbonate powder passes through the 10 computer temperature control areas at the speed of 5 minutes per time so that basic cobaltous carbonate is decomposed to generate the cobaltous oxide for the power battery in the positive pressure atmosphere. The invention saves the energy and has low production cost; in addition, the cobaltous oxide has great high chemical purity and physical performance and can be used as powder materials of the power high-performance and high-power battery.

Description

technical field [0001] The invention relates to a production method for powder materials used in the battery industry, in particular to a production method for preparing cobaltous oxide powder for power batteries. The international classification number is C01G51 / 04. Background technique [0002] Although the invention patent "Production Method of Subcobalt Oxide" with publication number 101200309 can produce a kind of cobaltous oxide with high cobalt content, the chemical purity of the product is not good, and the product contains nickel, iron, calcium, copper, manganese, zinc, The content of magnesium and other elements is too high, which cannot meet the requirements of various indicators for high-performance and high-power power batteries for battery materials. In addition, one needs to heat the reaction tank that produces the intermediate product cobalt carbonate and control the temperature to 50-55°C, which requires a lot of energy consumption; the other is to continuou...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C01G51/04H01M4/52H01M4/04

CPCY02E60/12Y02E60/10Y02P20/141

Inventor 周红阳

Owner 周红阳

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com