An Array Rod Laser Amplifier

A laser amplifier and array technology, used in lasers, laser devices, laser parts, etc., can solve the problems of inability to make large-diameter gain media, complex auxiliary circulation system structure, uneven gain distribution, etc., to improve energy The utilization rate, thermal management effect is good, and the effect of improving the utilization rate of energy storage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the embodiments and accompanying drawings, but the protection scope of the present invention should not be limited thereby.

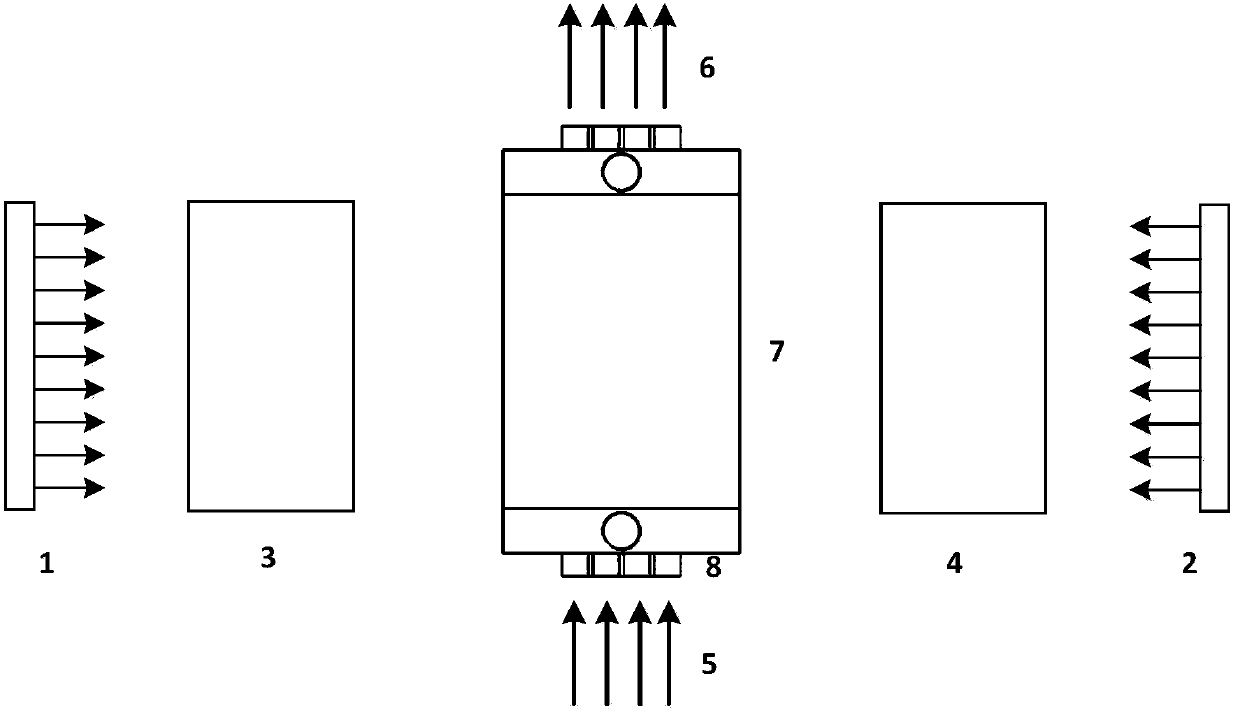

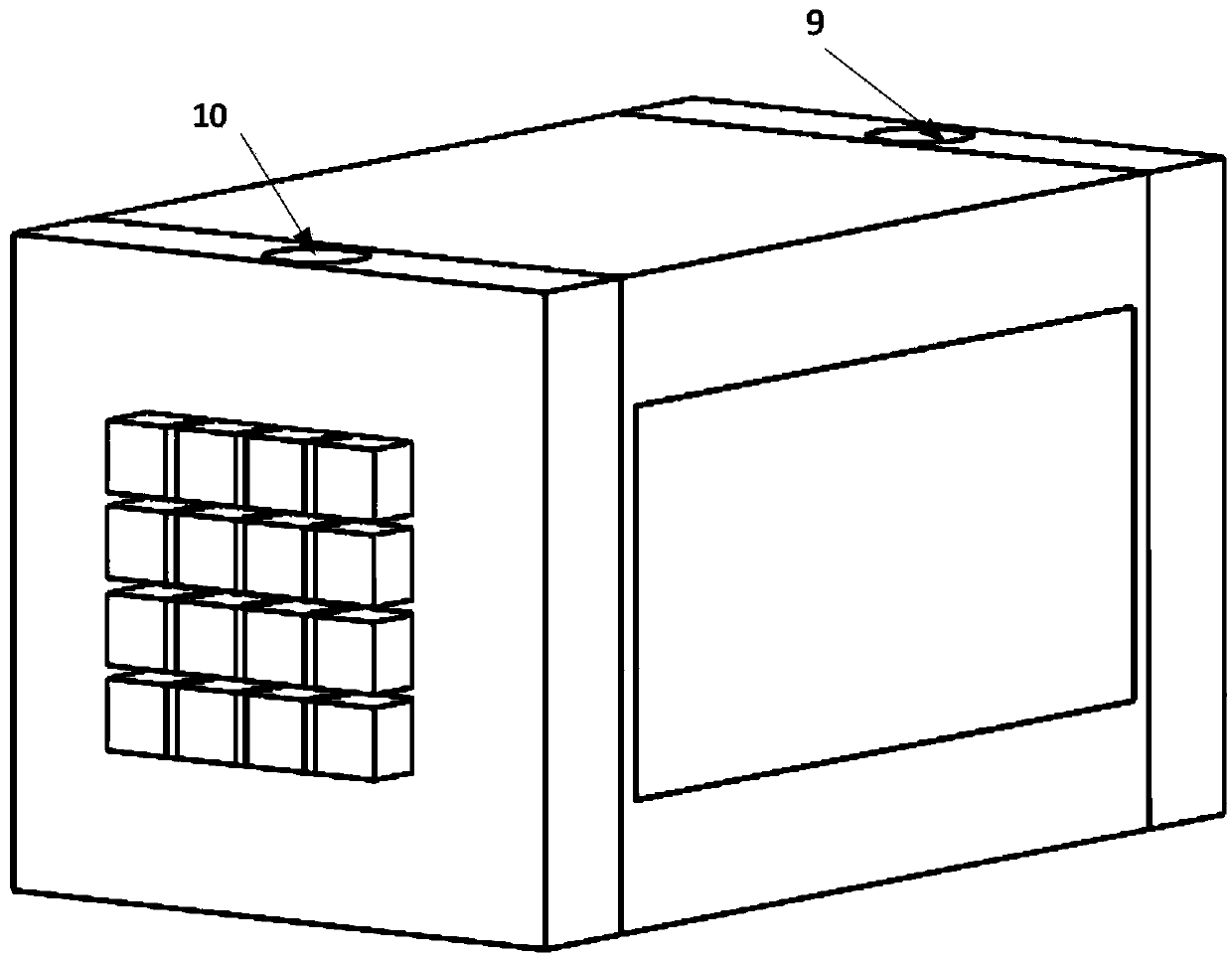

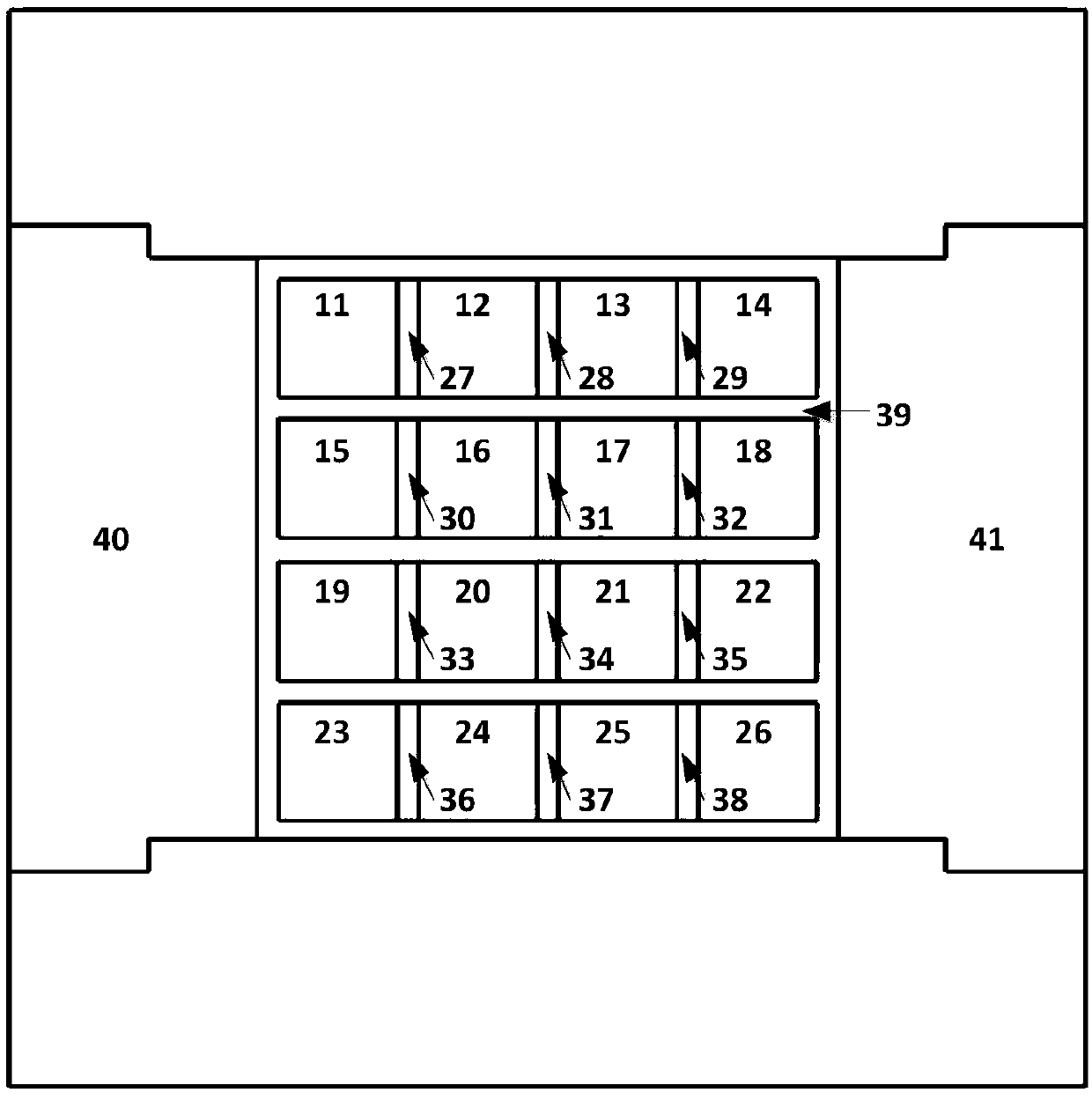

[0027] see first figure 1 , figure 1 It is a block diagram of the overall structure of the array rod laser amplifier of the present invention. Depend on figure 1 It can be seen that the array rod laser amplifier consists of four parts: pump source, coupling lens group, laser gain medium and mechanical structure. The pumping source includes two parallel and oppositely placed laser diodes 1, 2, the described coupling lens group is composed of two parallel and oppositely placed coupling lenses 3, 4, and the mechanical structure 7 has a positive effect on the laser gain The medium 8 provides a clamping and fixing effect. In the direction vertical and parallel to the side of the laser gain medium 8, there are light-transmitting windows 40 and 41 that are larger than the size ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com