Technological method for preparing Cr-doped beta-FeSi2 films

A process method and thin-film technology, applied in metal material coating technology, ion implantation plating, coating, etc., can solve the problems that the thin film does not have semiconductor properties, it is difficult to control the content of impurities in the thin film, and achieve the reduction of lattice parameters Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

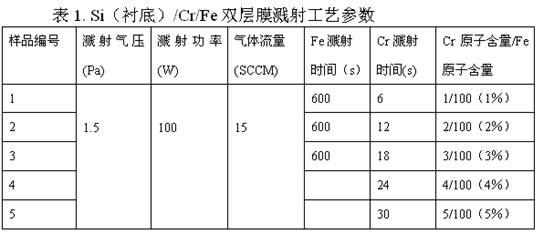

[0024] Embodiment of the present invention: implementing the technical solution of the present invention, using Si (substrate) / Cr / Fe double-layer film structure to prepare Cr-doped β-FeSi 2 The process of the thin film is as follows: the substrate adopts a p-Si (100) single wafer polished on one side, and the resistivity is 7-13 . Before the substrate Si chip was loaded into the sample chamber, it was ultrasonically cleaned in acetone, absolute ethanol, and deionized water for 10 minutes each, and washed with a diluted HF solution (HF:H 2 O=1:50) Soak for 30s-1min, rinse with deionized water, and use N 2Blow it dry, put it into the sampling chamber, and backsplash for 8-10 minutes to further clean the Si chip. The cleaned Si sheet is sent into the sputtering chamber through the magnetic transfer rod, and the preliminary vacuum is drawn to 2×10 -5 Pa.

[0025] Pass the working gas Ar gas into the sputtering chamber, adjust the sputtering pressure to 2.0Pa and maintain this...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| band gap | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com