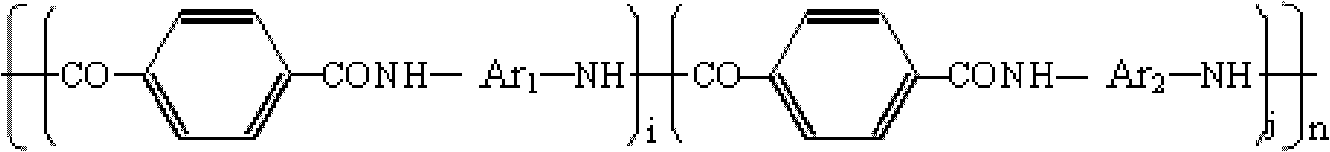

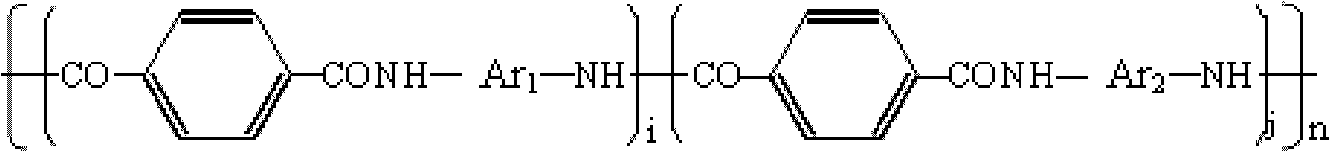

Method for synthesizing nomex resin containing fluorine and synthesized resin thereby and application

A technology of fluorine-containing aramid and polyarylamide, applied in polyamide coatings, single-component polyamide rayon, chemical instruments and methods, etc. Problems such as high-strength engineering materials and synthetic fiber technology fields cannot be applied to achieve the effect of high degree of polymerization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0051] Put 600g of anhydrous NMP into a three-necked glass bottle, then add 28g of anhydrous calcium chloride at 30-60°C to dissolve, add 14.4g of 2,5-difluoro-p-phenylenediamine and 2 at 15-30°C, 11.2g of 5'-diaminobenzimidazole, then add 30.4g of TPC at -15°C to 10°C at one time, remove the heat of chemical reaction with ice water under strong stirring, and then raise the temperature to 40°C after 2 hours The reaction was continued for 1 hour at ℃~70℃ to obtain a fluorine-containing aramid resin solution, and 44.8 g of fluorine-containing aramid resin was isolated. The intrinsic viscosity of the resin was 6.7 g / dl after testing.

example 2

[0053] Put 600g of anhydrous DMAC in a three-neck glass bottle, add 8.1g of PPDA and 10.8g of 2,5-bisfluoro-p-phenylenediamine at 15-30°C, stir to dissolve, and then put it at -15°C-5°C once more Add 21.5g of TPC, remove the heat of chemical reaction with ice water under strong stirring, and then raise the temperature to 50°C-80°C for 2 hours to continue the reaction for 1 hour to obtain a fluorine-containing aramid resin solution. The intrinsic viscosity of the resin is tested. It is 7.3g / dl.

[0054] Coat the resin on a 200mm×50mm polypropylene template with an applicator, volatilize at 20°C to 60°C to form a film, wash with water, and dry at 100°C to 130°C and 150°C to 180°C for 1 hour respectively. into a film of 30-50 μm. After testing, its dielectric strength reaches 80-105MV / m, and its surface energy is 21.5mJ / m 2 , The water absorption rate in boiling water for 1h is 0.8%.

example 3

[0056] Put 577g of anhydrous NMP into a three-neck glass bottle, then add 43g of anhydrous calcium chloride at 30-50°C to dissolve, add 11.3g of PPDA and 2,2'-trifluoromethylbiphenyl diphenylene at 15-30°C 14.4g of amine, and then add 30.4g of TPC at one time at -15°C to 5°C for reaction, use ice water to remove the heat of chemical reaction under strong stirring, and then raise the temperature to 50°C to 80°C to continue the reaction 1 hours, a fluorine-containing aramid resin solution was obtained, and the intrinsic viscosity of the resin was detected to be 8.9 g / dl.

[0057] After vacuum defoaming the resin solution, it is wet-spun in a coagulation bath composed of NMP, water and calcium chloride; then plasticized and stretched, the filaments are washed with water, and dried at 110-130°C to obtain fluorine-containing aromatic resin. Amid fiber precursors. The strength of the monofilament is 8.6cN / dtex, and the limiting oxygen index is 48.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Dielectric strength | aaaaa | aaaaa |

| Surface energy | aaaaa | aaaaa |

| Strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com