Novel anaerobic membrane bioreactor

A technology of anaerobic membrane organisms and anaerobic biofilms, applied in the field of new anaerobic membrane bioreactors, can solve the problems of anaerobic membrane bioreactors, such as reducing the treatment efficiency, reducing floor space, pollution, etc., and prolonging the cleaning cycle and service life, simple operation and control, and low economic investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

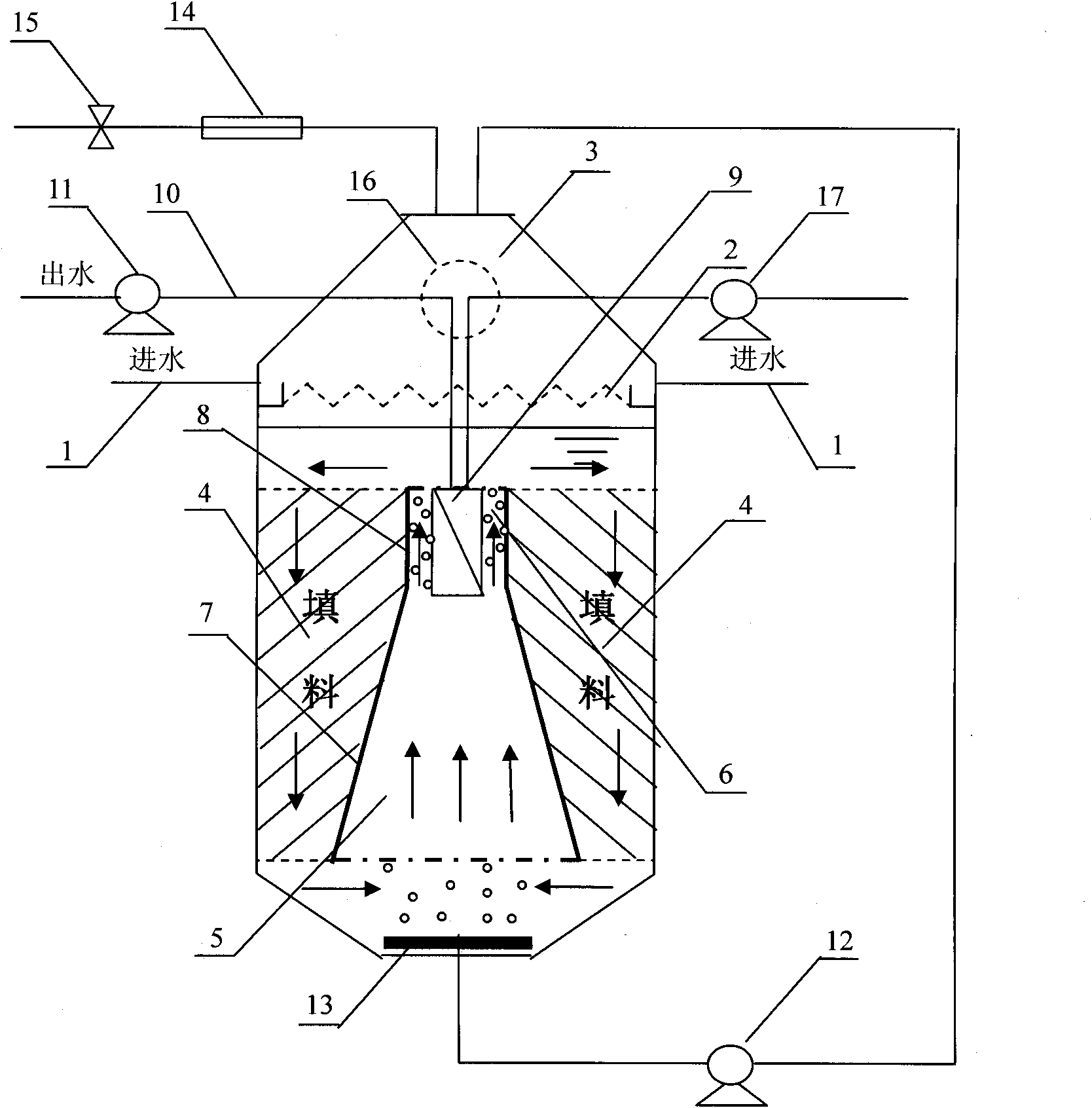

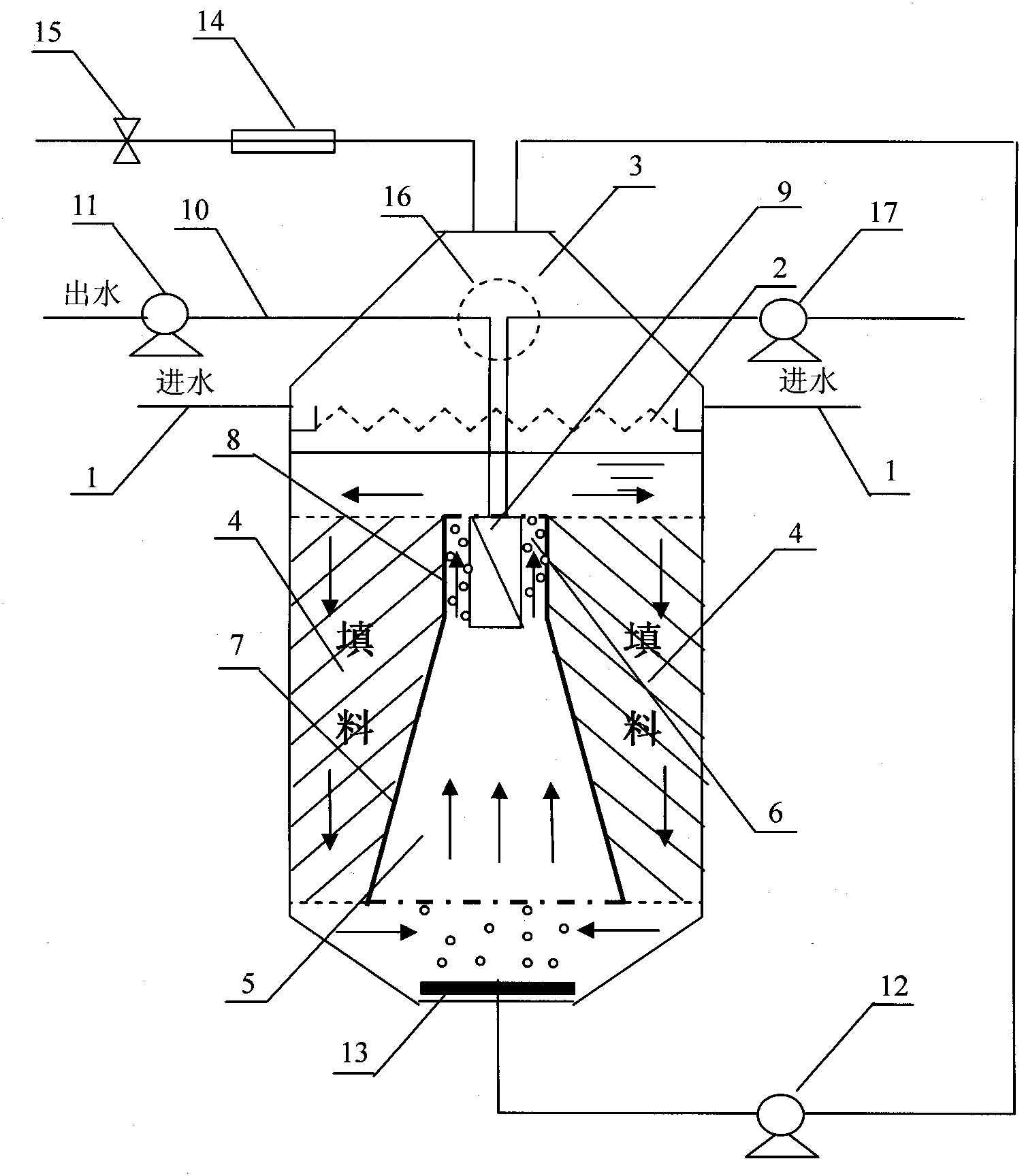

[0015] The present invention is further described in conjunction with the accompanying drawings.

[0016] In the new anaerobic membrane bioreactor, the water is fed through the upper water inlet pipe 1, and after the water is evenly distributed by the triangular overflow weir 2, it first flows into the biofilm area 4, which is a circular platform partition installed in the center of the reactor. 7. The space between the outer wall of the cylindrical partition 8 and the inner wall of the reactor, the upper and lower parts can be sealed with iron nets or fences, and filled with film-hanging fillers; water flows into the bottom of the reactor through the biofilm area, and the bottom is equipped with an exposure device. Aeration device 13, under the influence of aeration, water and activated sludge flow upward from the inside of the partition along with the gas. Due to the blocking effect of the circular platform partition, a large amount of activated sludge will stay in this area,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com