Perfluorosulfonic composite proton exchange membrane for fuel cell

A proton exchange membrane and perfluorosulfonic acid technology, which is applied in fuel cells, fuel cell parts, battery pack parts, etc., can solve the problem of providing membrane dimensional stability and proton conductivity at the same time, and affecting the overall performance of composite membranes and other issues, to achieve good mechanical strength and proton conductivity, benefit performance, and improve the effect of heat treatment temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

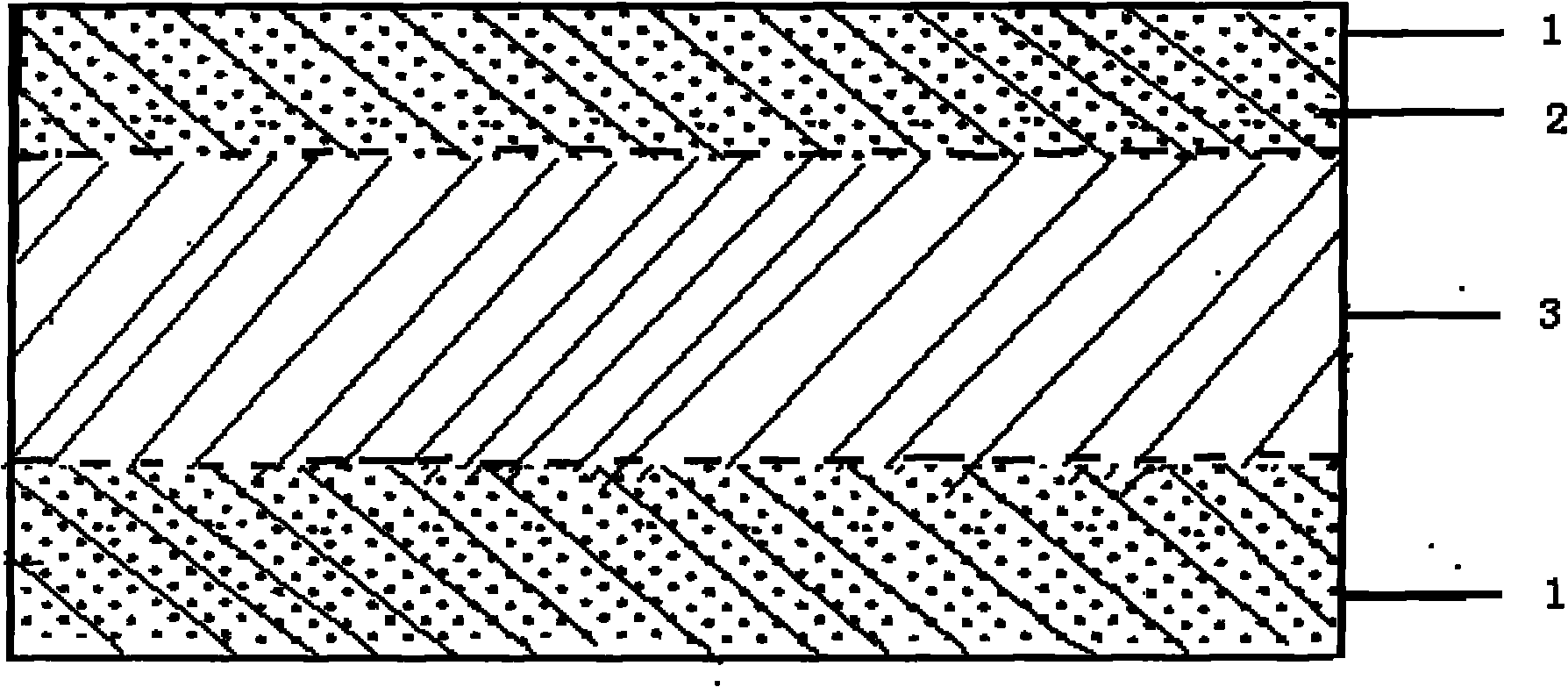

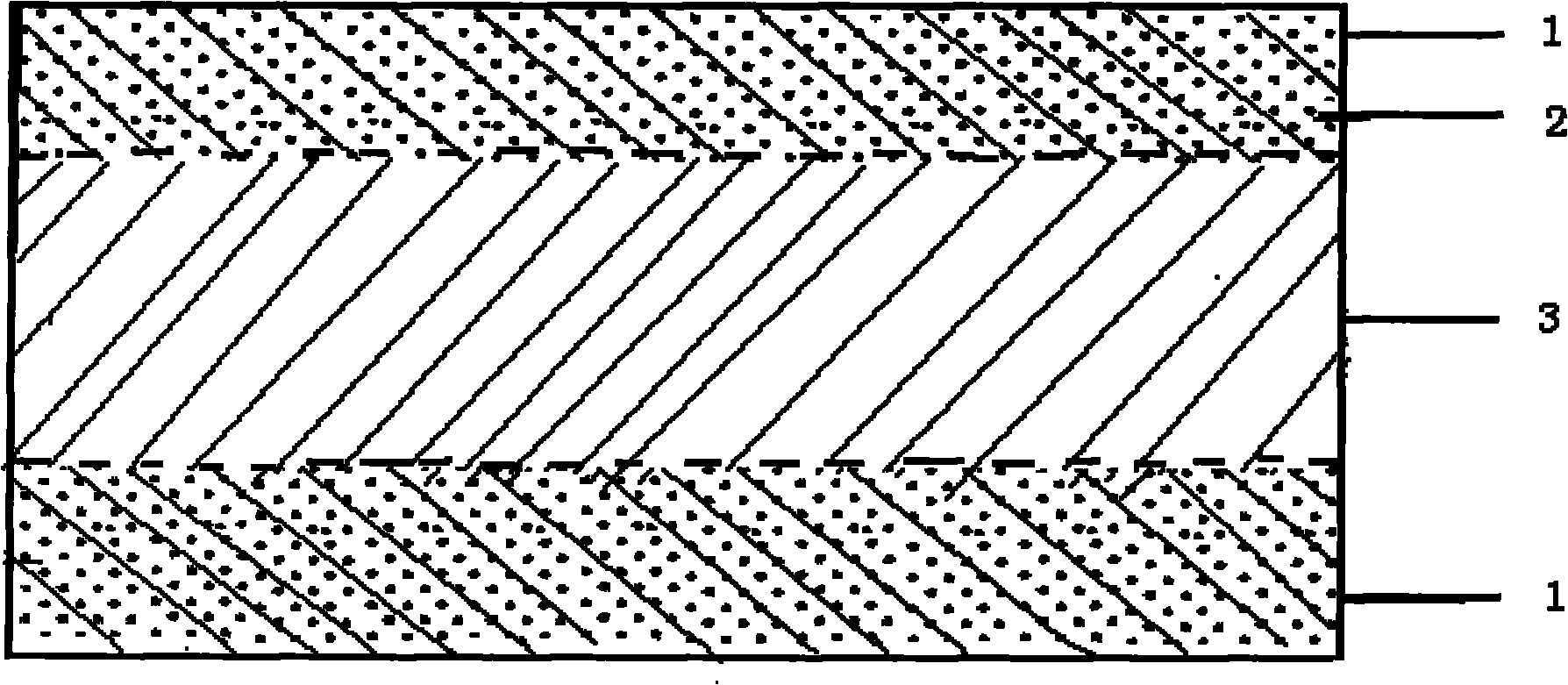

[0037]8g manganese nitrate is dissolved in 200 milliliters of ethanol-water mixed solution, wherein ethanol and water volume ratio are 1: 1, stirring and mixing make it form homogeneous solution, obtain the alcohol-water mixed solution of manganese nitrate; Get 10g perfluorosulfonic acid resin ( Chinafion, EW900), was dissolved in 200 milliliters of dimethyl sulfoxide, and prepared perfluorosulfonic acid resin solution; Adopted manganese nitrate ethanol water mixed solution to titrate the prepared perfluorosulfonic acid resin solution to a pH value of 7.5, obtained Manganese ion-type resin solution; a clean thickness of 20 microns porous polytetrafluoroethylene (PTFE) film (80% porosity) is placed in this manganese ion-type resin solution and soaked for 5 minutes, and then the excess resin on the surface of the wet film is easily removed, Place in a vacuum drying oven, adjust the temperature to 260°C, and heat-treat for 8 minutes; in order to completely block the internal pores...

Embodiment 2

[0041] Dissolve 8 g of manganese nitrate in 60 ml of ethanol-water mixed solution, wherein the volume ratio of ethanol and water is 1:1, stir and mix to form a uniform solution, and obtain the alcohol-water mixed solution of manganese nitrate; take a certain weight Shandong Dongyue Shenzhou Company The produced perfluorosulfonic acid resin (chinafion, EW900) is dissolved in N,N-dimethylacetamide to prepare a perfluorosulfonic acid resin solution with a mass percent concentration of 14.5%; the alcohol-water mixed solution of manganese nitrate is used The obtained perfluorosulfonic acid resin solution of titration is to pH value 7.5, obtains manganese ion type perfluorosulfonic acid resin ethanol aqueous solution; Clean thickness 18 micron porous polytetrafluoroethylene (PTFE) film (porosity 40% is placed in Immerse in this manganese ion-type perfluorosulfonic acid resin solution for 5 minutes, then remove excess resin solution on the surface of the wet film, place it in a vacuum...

Embodiment 3

[0045] Dissolve 8g of manganese nitrate in 1130 milliliters of methanol-water mixed solution, wherein the volume ratio of methanol to water is 1:1, stir and mix to form a uniform solution to obtain manganese nitrate solution; take a certain weight of perfluorosulfonic acid resin (chinafion, EW900) is dissolved in N, N-dimethylformamide, and the perfluorosulfonic acid resin solution that the mass percentage concentration is 0.7% is prepared to obtain; The perfluorosulfonic acid resin solution that adopts manganese nitrate solution titration to pH 7.5, obtain the manganese ion type resin alcohol aqueous solution; Place the clean porous polyhexafluoropropylene film (PTFE) with a thickness of 20 microns and a porosity of 60% in this manganese ion type resin solution and soak for 5 minutes, then remove excess water from the surface of the wet film After removing the resin solution, place it in a vacuum drying oven, adjust the temperature to 260°C, and heat-treat for 8 minutes; in or...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Proton conductivity | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com