Light intensity distribution analogy method of heavy-rubber ultraviolet light oblique incidence back etching process

A technology of light intensity distribution and ultraviolet light, which is applied in the direction of microlithography exposure equipment, photolithography process exposure device, special data processing application, etc., can solve the problem that it is impossible to simulate the light intensity of SU-8 adhesive ultraviolet light oblique incident backside lithography process Distribution and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

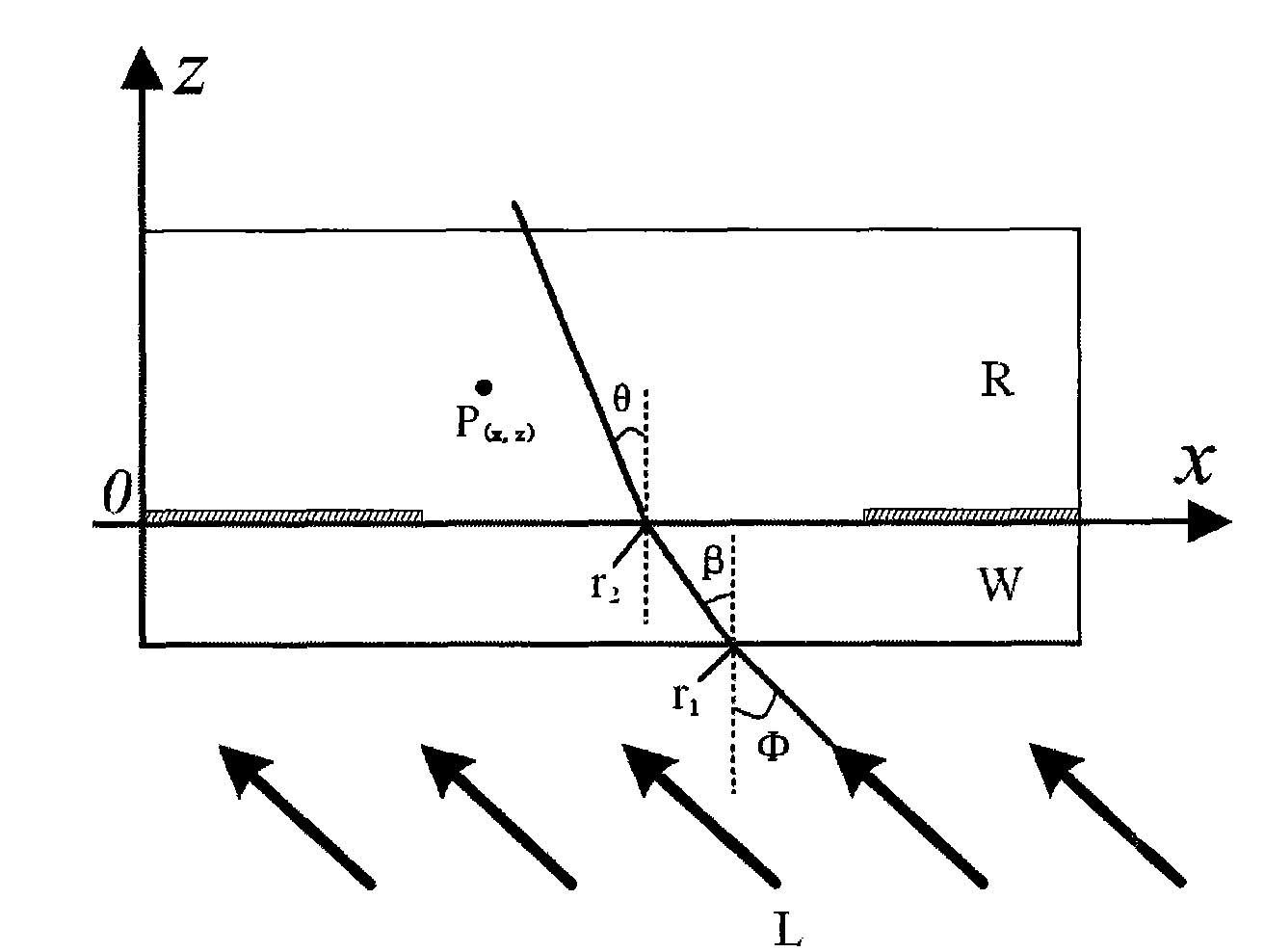

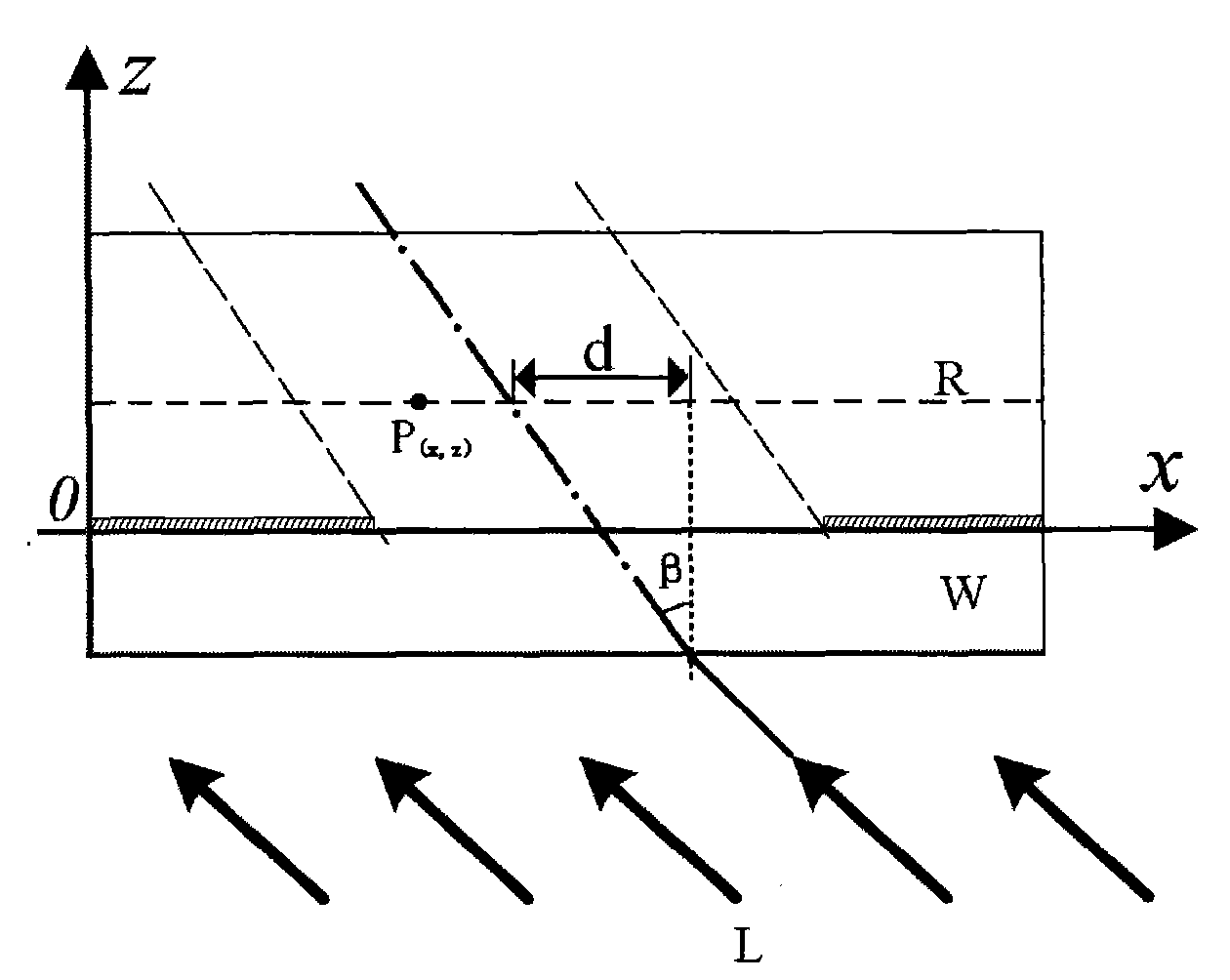

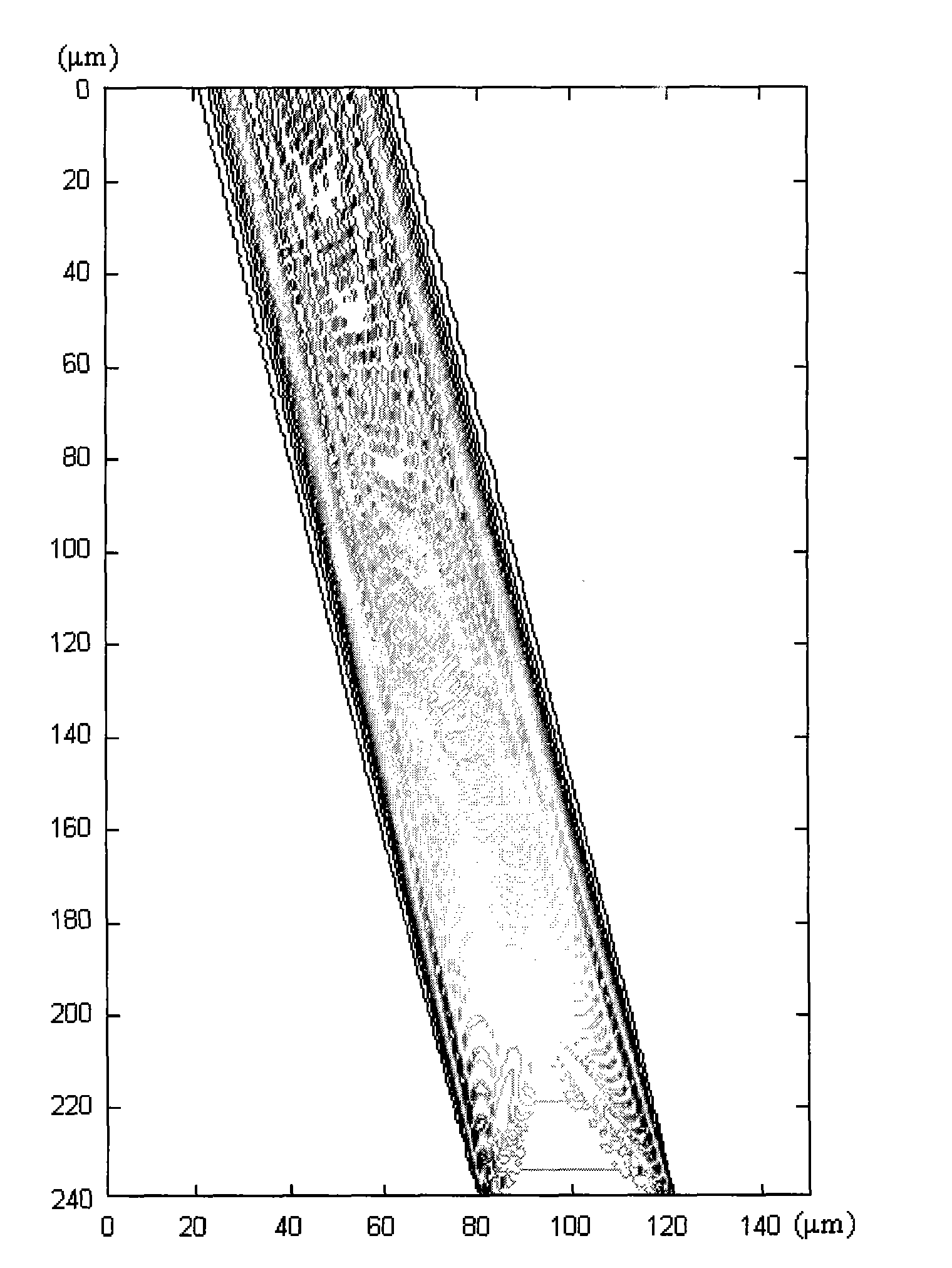

[0025] On the basis of scalar diffraction theory, the invention adopts the paraxial approximation technology of oblique incidence of ultraviolet light to process and simplify the Fresnel-Kirchhoff diffraction integral equation. At the same time, the refraction and reflection of obliquely incident ultraviolet light from the back at the interface of air / reticle, reticle / SU-8 glue, and the attenuation of obliquely incident ultraviolet light from the back inside SU-8 glue were considered. It can quickly and accurately simulate the light intensity distribution inside the SU-8 glue during the oblique incident backside photolithography process of SU-8 glue ultraviolet light. The basic steps of this method are as follows:

[0026] (1) According to the photolithography process conditions and parameters, input the left and right boundary coordinates of the mask hole (x 1 , x 2 ), the incident angle Φ of obliquely incident ultraviolet light in air from the back, and the wavelength λ of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com