Method for manufacturing liquid lens array capable of discretely zooming

A technology of liquid lens and manufacturing method, which is applied in the fields of lenses, optics, instruments, etc., and can solve the problems of no integrated manufacturing method, uncompact structure, and difficult realization of arrays, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

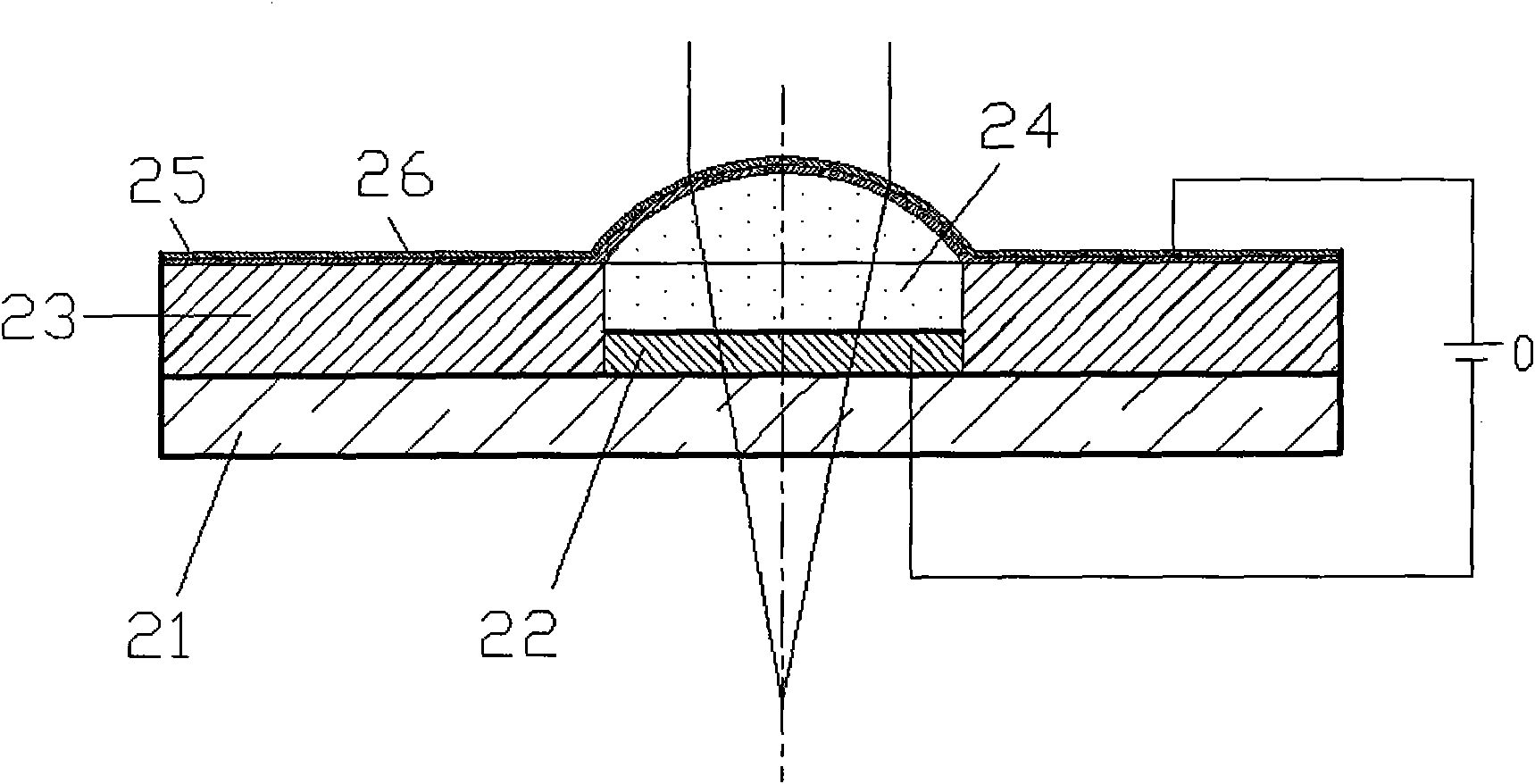

[0031] like image 3 , as shown in 8, the liquid lens array of the present invention that can be separated and zoomed is coated with a layer of transparent conductive film (such as ITO film) 22 as the first electrode on the glass substrate 21, and makes it into a certain discrete by the method of photolithography. A mesh-like distribution with pins, on which a layer of hydrophobic insulating medium 23 is coated, and a mesh-like distribution corresponding to the shape of the first electrode is made on the insulating medium, and the transparent conductive film. Inject a non-volatile insulating liquid 24 into the hole, and deposit a layer of transparent paralene elastic film 25 on the liquid by chemical vapor deposition to encapsulate the liquid in a closed space and control the Parylene The thickness of the forest film 25 makes it have proper elasticity...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com