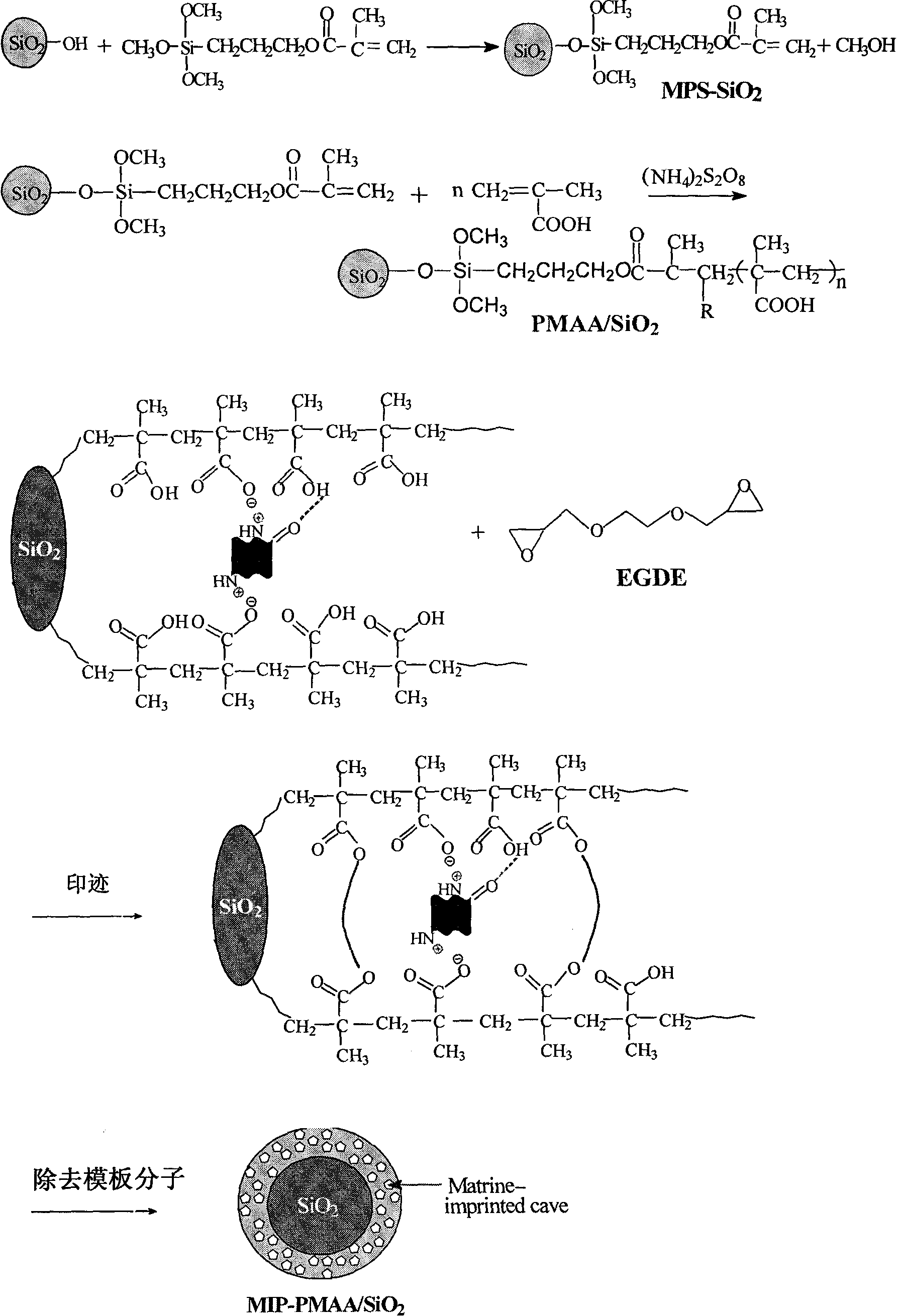

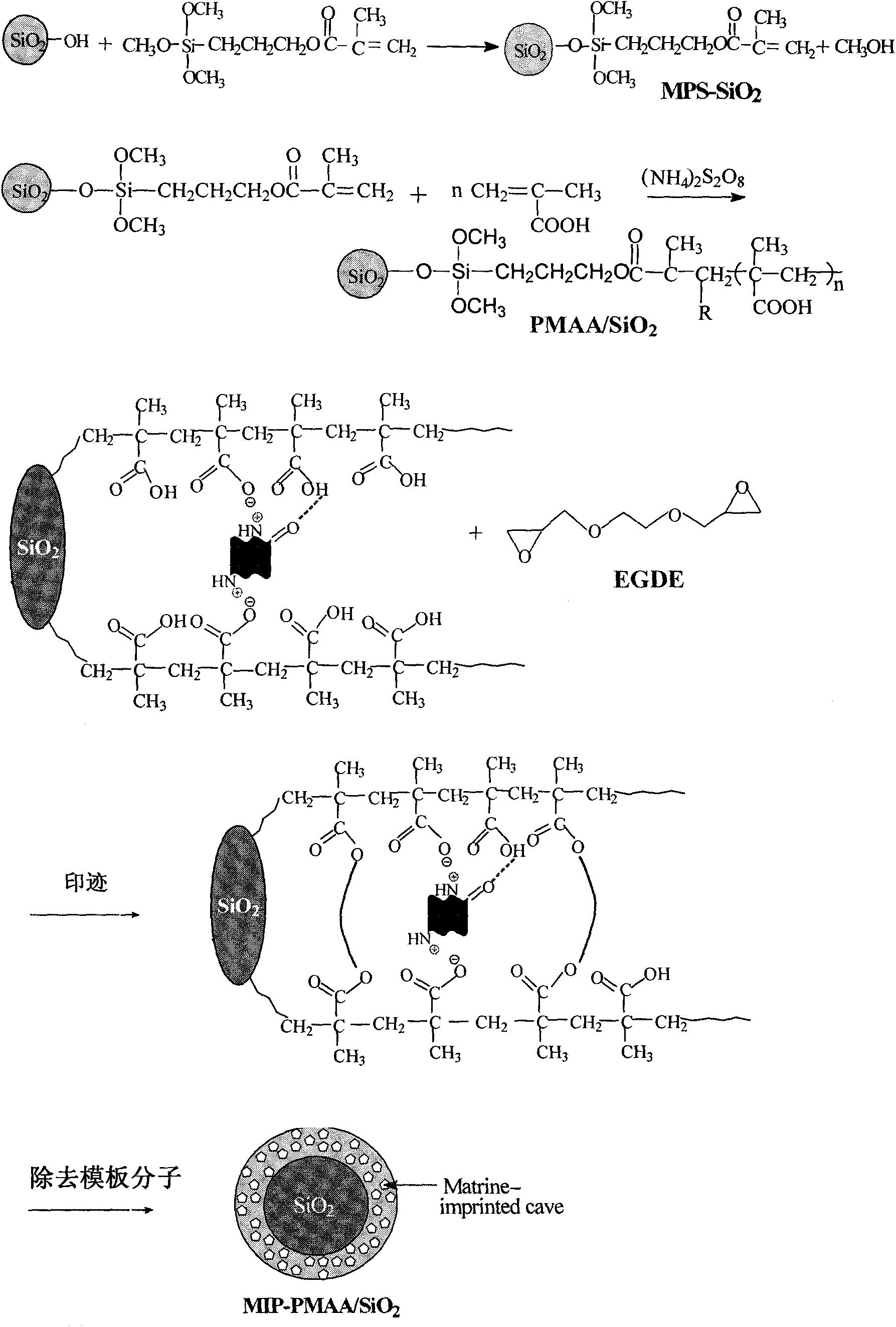

Preparation method of surface imprinted material for matrine substance separation and purification

A technology of surface imprinting and substance separation, applied in the field of preparation of ionic surface imprinting materials, can solve the problems of low efficiency of surface imprinting materials, and achieve the effects of low cost, strong identification selectivity and good selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Add 30g of silica gel particles to 150mL of 9% hydrochloric acid aqueous solution, stir and activate at reflux temperature, so that the surface of the silica gel particles has more hydroxyl groups, after 8 hours of activation, filter, fully wash the filter cake with distilled water, and finally put it in a vacuum oven Dry in a medium vacuum for 26 hours to obtain activated silica gel particles. Add 10g of activated silica gel particles into a four-necked flask, then add 360mL of ethanol and water mixed solvent with a volume ratio of 1:1 and stir, then add 10mL of γ-(methacryloyloxy)propyltrimethoxysilane KH-570, react at 48°C for 27h, after the reaction, wash the product with ethanol in a Soxhlet extractor to remove unreacted γ-(methacryloyloxy)propyltrimethoxysilane KH- 570, and finally vacuum-dried in a vacuum oven for 24 hours to obtain silica gel particles MPS-SiO modified by γ-(methacryloyloxy)propyltrimethoxysilane KH-570 2 . Add 200mL of water and 5g of silica ...

Embodiment 2

[0039] Add 28g of silica gel particles into 140mL of 5% hydrochloric acid aqueous solution, stir and activate at reflux temperature, so that the surface of silica gel particles has more hydroxyl groups, after 10 hours of activation, filter, fully wash the filter cake with distilled water, and finally put it in a vacuum oven Dry in a medium vacuum for 28 hours to obtain activated silica gel particles. Add 9g of activated silica gel into a four-neck flask, then add 330mL of ethanol and water mixed solvent (volume ratio: 1:1) and stir, then add 8mL of trimethoxyallylsilane, and react at 47°C for 24h , after the reaction, the product was washed with ethanol in a Soxhlet extractor to remove unreacted trimethoxyallylsilane in the system, and finally vacuum-dried in a vacuum oven for 30h to obtain modified silica gel particles MPS-SiO 2 . Add 230mL water, 4g modified silica gel particle MPS-SiO 2 and 10g methacrylic acid, with N 2 Exhaust the air for 30min, and in N 2 Stir under ...

Embodiment 3

[0041] Add 25g of silica gel particles into 145mL of 8% hydrochloric acid aqueous solution, stir and activate at reflux temperature, so that the surface of silica gel particles has more hydroxyl groups, after 9 hours of activation, filter, fully wash the filter cake with distilled water, and finally put it in a vacuum oven Dry in medium vacuum for 30 hours to obtain activated silica gel particles. Add 8g of activated silica gel to a four-neck flask, then add 300mL of ethanol and water mixed solvent (volume ratio: 1:1) and stir, then add 9mL of trimethoxyallylsilane, and react at 45°C for 26h , after the reaction, the product was washed with ethanol in a Soxhlet extractor to remove unreacted trimethoxyallylsilane in the system, and finally vacuum-dried in a vacuum oven for 28 hours to obtain modified silica gel particles MPS-SiO 2 . Add 250mL water, 3g modified silica gel particles MPS-SiO 2 and 12g methacrylic acid, with N 2 Exhaust the air for 30min, and in N 2 Stir under...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com